Siegwerk's blending centre targets growth market in Bangladesh

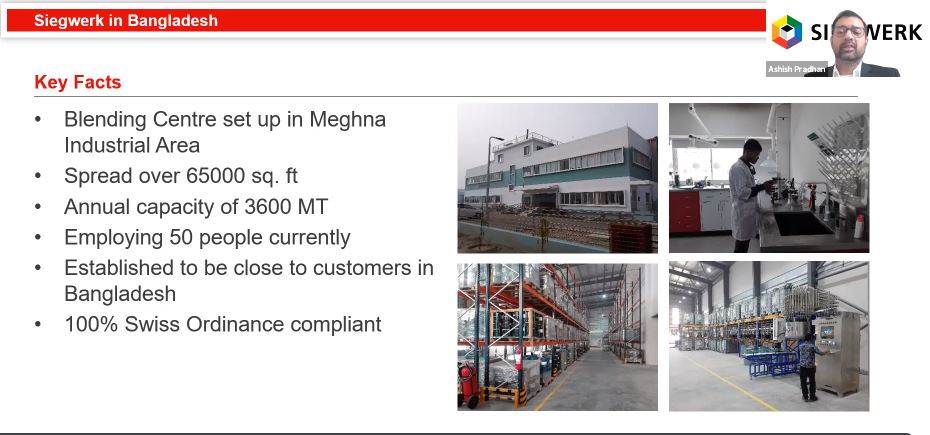

Siegwerk, the Germany headquartered leader in printing and packaging ink manufacturing is targeting the 900 MT packaging inks per month Bangladesh market. During a virtual press conference, Ashish Pradhan, the president of Siegwerk in Asia shared details of the new blending centre which has an annual capacity of 3,600 MT and will have close to 50 employees working in it.

13 Apr 2021 | By Rahul Kumar

Siegwerk inaugurated a new blending centre - spread over 65,000sq ft - in the Dhaka region in Bangladesh. The centre which employs 50 people in Bangladesh will reduce inventory costs to customers and allow Siegwerk to provide immediate technical support for local customers. With the addition of this centre in Bangladesh, Siegwerk currently has more than 31 blending centres worldwide.

Siegwerk has been supplying printing ink in Bangladesh since the mid-nineties. Ashish Pradhan, the president of Siegwerk in Asia said, "Siegwerk used to supply inks from its plant in India until recently." The centre has been commissioned and has been supplying blended inks since February 2021. This facility will help us solve technical issues locally and provide additional technical support with less turnaround time. Our customers now have the advantage of receiving faster response to their technical issues and selecting custom-made solutions that match their printing requirements.

Pradhan said, "The blending centre will supply Toluene free safe inks and is at par with global standards." This resonates with Siegwerk's aim of manufacturing and supplying toluene-free inks across the globe. Toluene or any raw materials containing Toluene, won’t be used as intentionally added ingredients in this facility. The inks produced will be compliant with global regulatory and brand owner requirements to ensure products are safe for end-use packaging applications.

Pradhan answered a query from WhatPackaging? magazine about monitoring "contamination of food items due to packaging inks and monitoring of raw materials supplies". Pradhan said, "The raw materials and intermediate products are as close to identical as possible, ensuring consistent product quality." He added, "Siegwerk has been aware of the need for safe printing inks for packaging applications from the beginning and has made ink safety one of its guiding principles. Siegwerk’s product safety guidance includes global regulatory compliance, brand owner requirements, and risk assessments. This ensures products are safe for the end-use applications. "

Pradhan mentioned that the Bangladesh blending centre will adhere to Sigewerk's global standards for the raw material process. He alluded "to a future" where formulation of inks will be made possible without mineral oils.

The operations for Siegwerk in Asia are headed by Ashish Pradhan, the president Asia, Siegwerk with Indian operations led by Ramakrishna Karanth as the CEO of Siegwerk India. Both of whom attended the press conference.

Siegwerk and Kotkamills partnership to benefit Indian converters

Ashish Pradhan took the opportunity to highlight Siegwerk's joining hands with Kotkamills, a Finnish paper and paperboard manufacturer. He said, the collaboration is based on the potential of water-based dispersion barrier coated paperboard to replace traditional polyethylene (PE) coated board. Pradhan said test trials have begun with converters on the Indian subcontinent. He said the switch in coating will reduce the environmental impact of the packaging.

Since 2018, Kotkamills has been producing barrier boards for hot cup and food packaging end uses, in addition to folding boxboard grades. The new water-based dispersion barriers make the paperboard compostable, repulpable and easy to recycle; the fibres used are from sustainable PEFC and FSC-certified sources.

See All

See All