Flex Films launches two new advanced BOPET film

Flex Films, the global film manufacturing arm of Uflex, has launched two new state-of-the-art BOPET films, at its manufacturing centre in Kentucky, USA. The first, FlexMetProtect-F-HBP-M is an aluminium foil replacement metallised high-barrier BOPET film. The second, FlexPet F-HPF is a puncture resistant, nylon replacement BOPET film.

24 Sep 2018 | By Rahul Kumar

FlexMetProtect-F-HBP-M is a metalised biaxially-oriented polyester (BOPET) film with a superior gas barrier that offers high moisture and oxygen barrier for virtually all applications, including aluminium foil replacement. High barrier comes from patented BOPET film technology, with high optical density specifically suitable for most flex pack product offerings. This film is 100% web inspected; using our advanced web metalised surface inspection system.

Speaking on the key highlights of the launched gas barrier, BOPET film F-HBP-M, Steven J Sargeant, general manager, technology at Flex Films, said, “With very high optical density, F-HBP-M film has superior tangible advantages. It is one side highly surface modified and other side metalised on corona treatment providing superior gloss, high tensile strength and advanced gas barrier properties. This film is suitable for extended shelf-life applications, including the replacement of Al foil in many flex pack configurations. Converters are able to generate less scrap and have less down-stream customer rejections due to improved film machinability and handling properties when compared to legacy solutions.”

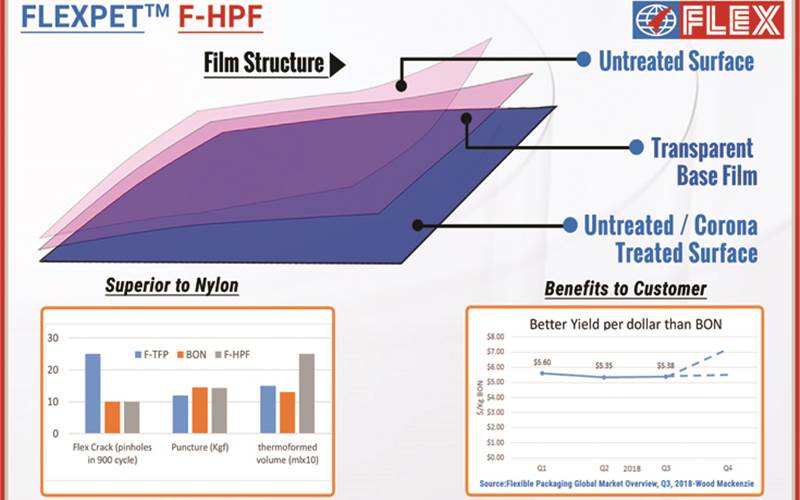

FflexPet F-HPF, a first-of-its kind biaxially oriented nylon replacement (BON) film made with a newly developed patent pending technology, offers important features of thermoforming performance, high puncture resistance and flexural fatigue strength. This technology is suitable for many applications, thereby providing a replacement for biaxially oriented nylon (BON) in many applications.

Explaining the properties of the puncture resistant BOPET film F-HPF, Sargeant said, “F-HPF is a transparent polyester film having the options of either both sides being untreated or one side being left untreated and other side being corona treated. Due to the enhanced flexibility of the film, it offers pinhole resistance, along with enhanced puncture and crack robustness. These class-leading properties enable this film grade to withstand aggressive handling. In addition, this grade avoids the typical pitfalls of BON like moisture absorption and other converter handling problems.”

Elaborating on the features of this product, Vijay Yadav, business head, Flex Films, said, “F-HPF Film is far more superior to nylon (BON) with fewer pin holes in terms of thermoform-ability whereas its puncture and flex crack resistance is at par with BON. Moreover, value proposition like better water resistance availability and compatibility with wide range of inks and adhesives makes it cost effective with greater yield per unit area as compared to BON, thereby remarkably accelerating our customers’ revenue.”

Anantshree Chaturvedi, vice-chairman and CEO, Flex Films International, said, “The biggest challenge that the packaging film industry faces currently is reducing food wastage through enhanced shelf life of food products, and reducing packaging material consumption through laminate rationalisation. F-HBP-M, with minimum bond strength of 200gm/ 25mm, has improved product efficiency with lower weight as compared to aluminimum foil. Features of it being compatible with a wide range of inks and adhesives; better availability and handling; good flex crack resistance and an advanced inline inspection mechanism in place to ensure consistency in barrier properties, will lend it a strong competitive edge.”

On F-HPF advantages, Anantsharee added, “We adopt a customer-first approach and by providing superior quality assurance, we enable our consumers to achieve better revenues. Developing F-HPF film with excellent thermoformability and availability is in sync with our endeavour to constantly keep inventing ourselves and provide value creation to the brand owners we work with.”

See All

See All