CDC’s Drupa shopping bag has a Cron CTCP

Kolkata-based CDC Printers has invested in a Cron CTCP UVP4648GI with a Shangzun TPD 1100 plate processor. The kit was ordered during Drupa 2016.

20 Jul 2016 | By Noel D'Cunha

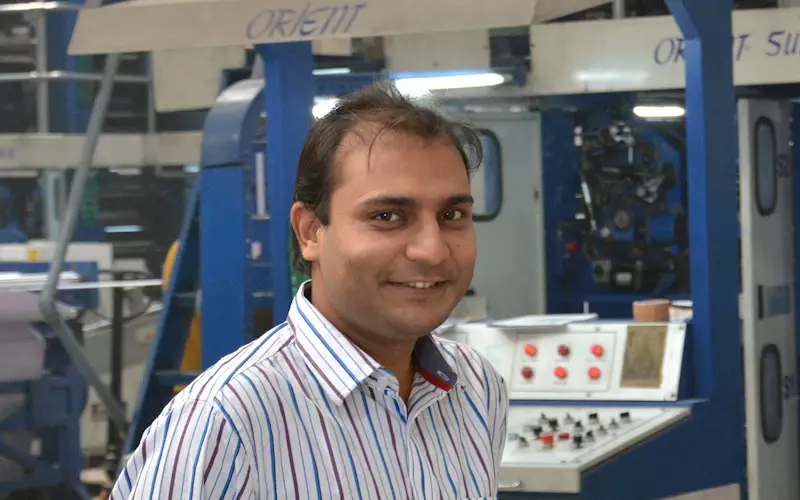

The father-son duo, Chittaranjan Choudhury and son Manu, owners of CDC, said they are looking to make their second plant, a book printing unit setup four-years ago, self-sufficient. “Here we are using coldset web offset as the print method, and plates required are sent from our city office in Kolkata,” said the younger Choudhury.

CDC converts around 800 tonnes of paper during peak season. The screen ruling that the types of books produced by CDC require around 100-120lpi, where Manu said, the dot gain/loss would be under 1 percent. “Since all the plates would require around that lpi, we thought of putting a CTCP, which would reduce our plate cost. Between the Cron and other CTCPs, we opted for Cron because of the price advantage.”

CDC presently fires around 15,000 plates on a Kodak Trendsetter 8-up CTP, and with the new CTCP, Manu said that number may not necessarily increase. “We are happy with the production of plates using the Kodak platesetter, but as I said earlier, the primary reason we opted for this CTCP was to make the other unit self-sufficient.”

For CDC though, the cost comparison between a CTP and CTCP was not much, but the running expense was what mattered. “We are expecting at least a 20% growth with the book printing unit this year, and I am sure Cron would be sufficient to meet this growth. I am also hoping for a very less downtime and of course a very good return on investment,” said Manu.

Mumbai-based Nippon Color facilitated CDC’s Cron buy. Besides CDC, Nippon signed seven more deals – six Cron and a Kodak thermal CTP.

|

See All

See All