Valco Melton showcases adhesive solutions for Indian industry

There are many ways to palletise. And the US-based Valco Melton demystifies the importance of adhesive dispensing systems to ensure stabilisation in palletising

16 Sep 2019 | By WhatPackaging? Team

Palletising with adhesives is a low-cost alternative to methods such as tape, cord, strapping, and shrink, stretch or paper wrapping. Using hotmelt or cold glue formulations which have been specifically developed for palletising and readily available from most adhesive suppliers, the average pallet load can be stabilised for about Rs 3.5, says Valco Melton

When considering palletising adhesives, you essentially have two types: hotmelt and cold glue formulations:

- Non-skid adhesives that remain tacky after application. This means the bond can be broken and rejoined without damage to cartons or loss of adhesives strength

- Breakaway adhesives that require time for drying after application. They can be separated without damaging the carton. However, once the bond is broken, the adhesive loses its characteristics and another application is necessary to provide pallet stabilisation.

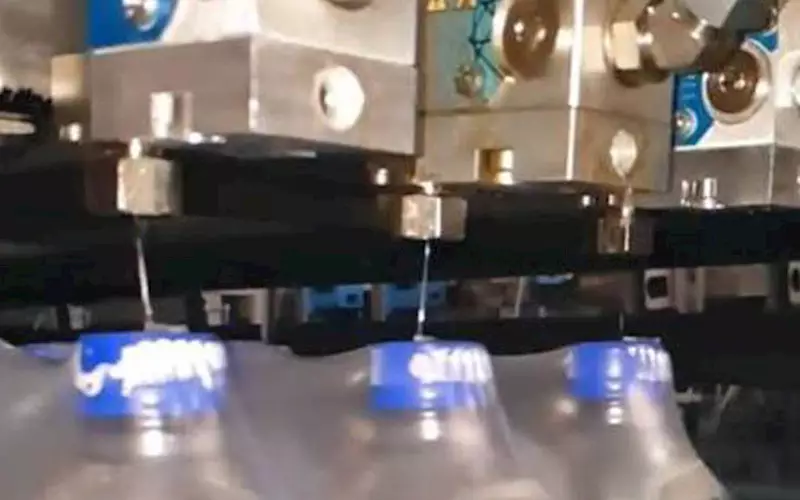

Bad palletisation – Pallet collapses during transit due to being used for conventional methods

The merits of pallet stabilisation

The improvement in the stability of the pallet will provide greater returns in the form of reduced damaged products, reduction in the use of stretch wrap and any additional interlayer sheets that might be being used.

The adhesive applied forms a layer and provides antiskid properties to the cases keeping them from falling and in place while transportation. This is especially beneficial for places with poor road conditions. The unloading process is simple and does not require any extra machinery for case separation.

In addition, the Valco Melton engineering team ensures that the application is integrated into the existing production line with almost no downtime giving complete flexibility and immediate improvement.

Valco Cold Glue and Melton Hot Melt have joined forces to provide an extensive selection of adhesive dispensing equipment. Container weight, the open time before stacking, materials handling procedures, required type of bond, the environment and the packaging material, all are factors in determining which method to choose. Each type of adhesive application, whether extruded or spray, has its particular benefits.

Valco Melton is a manufacturer of adhesive dispensing systems and quality inspection machinery who work with OEMs and end-users to find successful solutions. A Valco Melton consultant can help determine which method is best for a specific application

See All

See All