The Covid chronicles of a gen-next die-maker

Raju Kutty of Purandara Laser Technologies shares how his company survived the onslaught of the pandemic. He shares with Ramu Ramanathan how he forged his path in the craftsmanship of die-making

29 Jul 2021 | By PrintWeek Team

Nothing could have prepared Raju Kutty for 2020-21. The managing director of Kochi-based die-making company Purandara Laser Technologies (PLT) braced himself for the struggles. Keeping up-to-date with the complex government regulations proved to be a major part of what the company was doing during the pandemic months.

“We were spending all our time and energy figuring out how the company should do the most basic things such as paying salaries, statutory liabilities such as PF, ESI, GST and so on,” says Kutty. All things considered, it is surprising to know that the company did better than expected. “I have learnt that keeping your cost structure frugal is really important to improve the overall efficiency,” says Kutty.

History has shown that an organisation that prepares itself is better equipped to outperform the unprepared during a turbulent time. “There is going to be a boom once the Covid pandemic phases out. It’s better to preserve your energy, your precious working capital and your team for that,” says Kutty. “Now is the time to have a closer look at the health of our balance sheet and ruthlessly cut down costs and liabilities.”

He believes that one should not opt for moratoriums or any perceived short-term reprieves if one can ride through the tough phase. “The most important thing is, do not cut corners with your most precious resource – your people,” says Kutty firmly.

Die makers need to boost their technology and automise their workflow. Raju Kutty feels that this is the most effective way of flourishing in the die business

Taking the challenge head-on

Last 12 months had been especially challenging for businesses in the Kerala market. The companies didn’t even know what was going to transpire in the next six hours, let alone the next day or next week. Kutty says that PLT and its extended family in the industry had to reboot to cope.

“Most of us were, and even today are focussed on the basics right now. How to pay your employees on time, how much to pay them, what to do with your commitments to banks, whether to restructure your loans or tough it out and keep paying them, how to pay your suppliers so that they do not suffer on account of your cash flow problems – these were the basic things to focus on,” says Kutty.

PLT stuck to its tried and tested business model. “Not much of digital marketing unfortunately. Since we deal with a steady base of long-term customers, it has worked for us, so far,” says Kutty.

Measured optimism is something that provides hope according to Kutty. A thing most of the companies and individuals in Kochi have been doing is to cheer each other up. This is proving tougher in 2021 as compared to 2020. “If we can somehow see through this phase, just keep our heads above water, then better days are bound to come sooner or later,” says Kutty.

PLT faced quite a few challenges during the two lockdowns. It affected the business in a big way. And along with it came a system in place “for rotating teams, arrangements for our people to stay, routine things such as permissions and police passes. This year we were able to replicate exactly what we were doing last year during the lockdown.”

Today, the core company Purandara has 120 employees working across its offices in Kerala and Tamil Nadu

Packaging hub in Kochi

PrintWeek has reported how innumerable commercial printing ventures in Kochi have diversified into packaging. This trend accelerated in 2020. “It worked in our favour. And most of the packaging jobs were in the domain of food and medicine packaging,” says Kutty.

The converters were able to penetrate the market during the period of lockdown when customers started looking out to scale up local vendor supply chains. This worked in favour of the converters in Kochi and all this led to a development in the packaging business.

Kochi now sees more customers preferring corrugated micro fluted boxes and rigid boxes for packing their products. “This could be due to the effect of eCommerce. When it comes to printing such products, UV becomes the preferred method due to the instant drying property of the inks as well as the strength of the adhesion of the ink,” says Kutty. “I also believe flexography would start getting more popular as the days go by; due to the

increased level of quality that is achievable using the flexographic process.”

The Purandara tech team is led by tech director NR Premkiran plus senior directors KD Rajarathnam and R Shanmugasundaram. Along with Raju Kutty they are the four pillars upon which the business has been built

Packaging and areas of discontent

The boom in packaging brought along with it the concern areas, which are prevalent in the packaging industry of India. “There is a tremendous paucity of manpower that can understand the tricky areas of packaging; how to optimise the usage of a folder gluer for instance. This is the reason for many of the challenges in folding cartons,” says Kutty.

Areas such as adhesives or UV printing or coatings are subjects in which in-depth understanding can lead to improvements. “When a problem arises in the application or formulation of a coating or adhesive, those protective, enhancing and functional substances can be the sole reason for a job’s rejection,” feels Kutty.

Plus, the post-Covid-19 scenario has led to a reversal for design innovation in packaging. Kutty found that there was “very little interest” in developing unique designs in packaging and “customers were sticking to tried and tested typical carton designs”.

“For instance, before Covid-19 customers used to experiment with innovative designs for even simple products like Christmas cakes or jewellery boxes. Now even such customers confine themselves to what works best. They do not want to spend money or time designing new stuff,” says Kutty.

Humble beginnings

Whenever you meet Raju Kutty, he will always remind you of PLT’s humble start. His father MV Narayanan Kutty started this company as a trading house for printing materials in the 1987. The small room at Thrissur where his father and his partner Gopinathan Nair established Purandara Trading continues to be the branch office at Thrissur.

“It is a place which I never feel tired of visiting (Kutty calls it his tharavad - ancestral house).” Even today, PLT tries to host most of the company functions in Thrissur; even though the company has branched off in Coimbatore and Kochi.

Kutty owes his career to his father. “He mentored me pretty much every step of the way and still does,” says Kutty. “The way he is able to see things in a larger picture is a big reason we are able to make a mark in the verticals that we have invested in.”

This gets exemplified by the fact that PLT makes special colour inks for challenging packaging jobs; along with the precision dies needed for the same jobs. The company prides in this rare combination of doing both together. Kutty says that it was one such thing that was “an outcome of my father’s motto of true happiness comes from giving, not receiving. And he proved this by example, every step of the way.”

When PLT was starting out, most of the companies doing this business in India were hard core die-makers who then added machines and to automise their work flow. Kutty feels that this is the most effective way of flourishing in the die business. He doffs his hat to his fellow travellers in the die-making business: Pandiyan Yadav of Ashok Punch Arts, Biren Naykpura of Son N Naykpura or Vishwanath Sanil of Zenith Die Makers.

“I have a great admiration for these gentlemen who live and breathe the subject. We are more of a die-maker by accident and it happened when we identified a gap in the market and decided to fill it,” says Kutty.

PLT has always been an organisation with shared values. It led to a people-oriented approach. “We invest heavily in our people, making sure that they understand the intricacies of die-design and tooling. Most of our designers and toolmakers have garnered a hands-on approach simply by working with our customers through their production process,” says Kutty. It has enabled them to build a team of focussed, committed individuals

that has been able to survive in this tough business for the past 12 years. Today, PLT has 120 employees.

Personal story of learning

Experience has been a great teacher for Kutty who graduated with a Bachelor of Science in Chemistry and Post Graduate Diploma in Business Management. The initial days at the company were spent doing the most basic stuff, such as selling material to the printers and collecting money from them.

“We were also selling equipment and the association with Proteck gave me the opportunity to learn things from V Vaidyalingam of Suba Solutions whose zeal for work and ability to convince customers left a profound mark.” Kutty fondly recalls the pride he felt after the first purchase order for a Proteck plate exposing system and handing it over to Vaidyalingam. He was 23 years old at that time.

Similarly the work with the TechNova team, represented by R Shanmugamsundaram in Coimbatore – another teacher in the journey of Kutty and also a co-director at Purandara today – represent some of his best memories. “TechNova did a lot of focussed tech-work, introducing the use of proper chemistry which was considered a luxury in those days – they invested a lot of their resources in making printers understand the use of

fountain solutions and washes,” recalls Kutty.

For Kutty, the above two instances have represented the most fun element of salesmanship. He is a great admirer, and also a staunch practitioner of “the art of convincing a customer of the value that you bring to the table.” Till date, what remains as the most exciting aspect of his work “is going to a prospect’s place with my bag and coming out with the expectation that I have probably won a new customer.”

PLT in 2021

For PLT, the pandemic restrictions resulted in people getting more tolerant of each other. “When half your team is prevented from attending work, how is it possible to be as productive as usual? And we have learnt to work remotely,” says Kutty.

A simple application such as Team Viewer was a boon for PLT and it managed to provide customer care, design and accounts working from home. “Initially it was a fascinating sight to simply see our computers working on their own, because our people were working remotely. So we have largely been able to retain our customers and our product design/development cycles are as robust as before,” says Kutty.

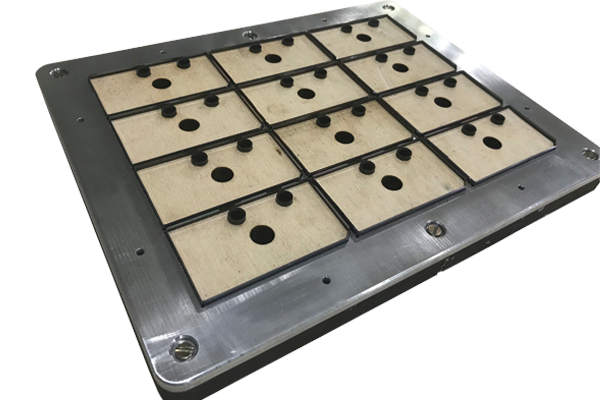

PLT operates in two states of Kerala and Tamil Nadu. Its verticals are typical to any other die-maker and it manufactures normal dies, stripping dies, embossing/foiling dies and special application dies for products such as gaskets and medical devices.

“We earn better revenue on specialised work such as multiple level embossing, micro foiling and special application dies. These dies involve more craftsmanship at our end,” says Kutty. The bulk of the revenue comes from “simple bread and butter packaging dies, which can be completed in volumes,” says Kutty.

PLT has a cordial relationship with Bobst, Suba Solutions and other brands working in die-cutting domain. Another notable partner is Autoprint. Kutty says, “Autoprint has a very interesting solution for small time printers/die-cutters looking for their first automatic die-cutter. We see a lot of printers benefitting from their solutions. Our work involves us working hand in hand with the engineers mainly when it comes to designing and fine-tuning dies for the customers.”

PLT has held it head high in the midst of a reeling effect of business getting affected owing to lockdowns. On a personal note, Kutty finds that the absolute fear of the disease is where things start to change. “The second wave played havoc with our psyche and seeing the news became the most painful thing of the day.” He suspects that the biggest damage suffered in 2021 was more mentally and it will take some time for us to feel normal again.

“Hearing about losing someone or actually losing relatives and friends was a nightmare that we lived on a daily basis,” says Kutty. Personally, it has been painful for Kutty to lose friends in the pandemic. Furthermore, he says that he is afraid that “we have not seen the whole of it yet and I only hope it doesn’t get much worse than this.”

Books and Netflix proved to be a balm for him. Lockdown forced him to reconnect with some of his old friends from school and college. It acted as great source of support “Personally I consider myself very fortunate, as compared to lakhs who have suffered a lot,” concludes Kutty.

Raju Kutty’s tech-talk about die-making

On the advantage of CNC Engraving technology for a converter: CNC Engraving technology enabled us to make this special high precision die for high precision gaskets. The technology is flexible and can be used for cutting wide variety of materials.

On sandwich dies: After extreme long runs the rules of the die might bend a little resulting in a minute deformation of the gaskets and in one such case the customer could not afford that. So we thought of reinforcing the blanks with a metal on top. Companies such as Marbach specialise in such dies which are called – sandwich dies. These are used in applications like cigarette cartons mainly, where extreme long runs and high precision are the norm.

On the benefits of special mirror finished rules: Mirror finish rules, ground finish rules come with special coatings on the rule edge and these typically enable you to achieve cleaner cuts with less problems of angel hairs and dust. Of course these have to be accompanied with the right hardness of ejector rubber also to achieve optimum cuts.

On whether brands should be aware of mirror finished rules: Brands will benefit if they know about it. In the case of dies it is better to pay a bit more for a better quality rule since the cost of the die is amortised over long runs. Most converters who are our customers instinctively understand this.

On the one thing every packaging designer in India should know about a die: The thickness of a laser beam is 0.7 mm. So do not place your blanks at a distance less than double of that.

On what is the new normal in the design of a dies: In the design of dies there is no such thing as a new normal. It is all the same. There are new manufacturers cropping up for things like masks and sanitisers and all of them stick to the most basic of packaging.

On the plan for the raw materials of dies in these uncertain times: This has been really tough and getting supplies has always been one of our top worries. On the other hand, we found that more suppliers are entering the business for the raw material as there are more die-makers around now.

See All

See All