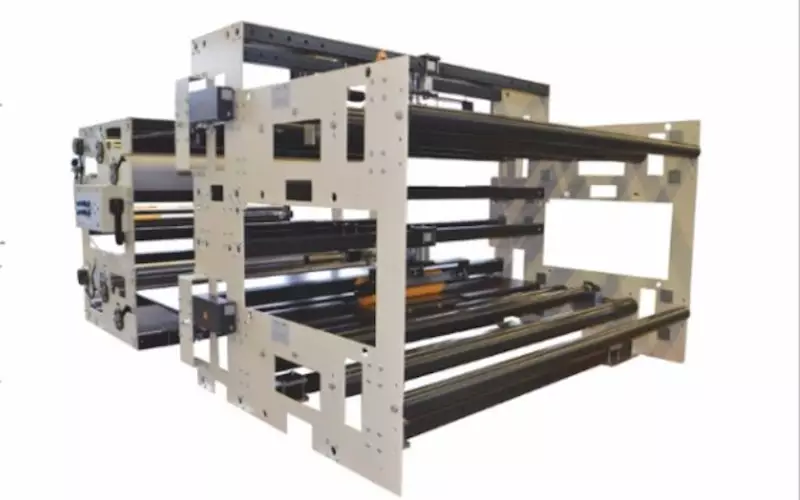

ProductWatch: Erhardt & Leimer’s web alignment system - Corraligner

During the IndiaCorr show at Bombay Exhibition Centre, Mumbai, Erhardt & Leimer showcased its web alignment and web tension controller system. Amit Gupta, sales manager, India, briefed the WhatPackaging? team members

18 Nov 2022 | By WhatPackaging? Team

WhatPackaging? (WP): Name of the product:

Erhardt & Leimer (EL): Corraligner (web alignment system) and Tension Master (web tension controller)

WP: What does it do?

EL: The Corraligner maintains the alignment of paper before lamination and the Tension Master maintains the tension of the web.

WP: Explain what it's suitable for?

EL: It is suitable for proper alignment on an automatic corrugation line before the application of a triple heater.

WP: When was it launched?

EL: It was launched in 1988 in Europe and in 2008 in India.

WP: What market is it aimed at?

EL: The Corraligner is targetted at the automatic corrugation machines market.

WP: In what way is the product relevant for Indian packaging in the SME sector?

EL: As paper is a basic material in the corrugation industry, it helps save paper wastage and reduces the dwell time of the machine. This product also helps to improve the quality of the corrugated boards.

WP: How does it differ from similar products in the market?

EL: It has DCS technology which provides high accuracy and is ensured by a closed-loop operation.

WP: What's the USP?

EL: The automatic functioning of the Corraligner ensures that wet-end grade changes can be made without any operator input and without the need to reduce the line speed of the corrugator.

WP: How easy is it to use?

EL: It is simple to use. As the Corraligner has automatic functioning, it reduces the activities of the operator

WP: How does it score on the merits like being trouble-free?

EL: It uses a non-edge contact guiding system which removes the common issue of single faced web brakes and loss of machine productivity.

WP: Any feedback from your customers?

EL: The machine has been running on hundred systems in India and we are getting repeat orders for the same.

WP: What kind of manufacturing compliance does your company follow in India?

EL: Erhardt and Leimer follow the pattern of batch production for components.

WP: What’s the price?

EL: The price ranges from 20-30 lakh.

WP: Key customers?

EL: Horizon Group (Four lines)

Avon Containers (Three lines)

Ujjain Packaging (Three lines)

KCL Limited (Three lines)

Wadpack

TGI Packaging and many more

WP: Contact person and details:

EL: Amit Kumar Gupta, manager - sales, India, Erhardt & Leimer India

EMail: AKGupta@erhardt-leimer.com

See All

See All