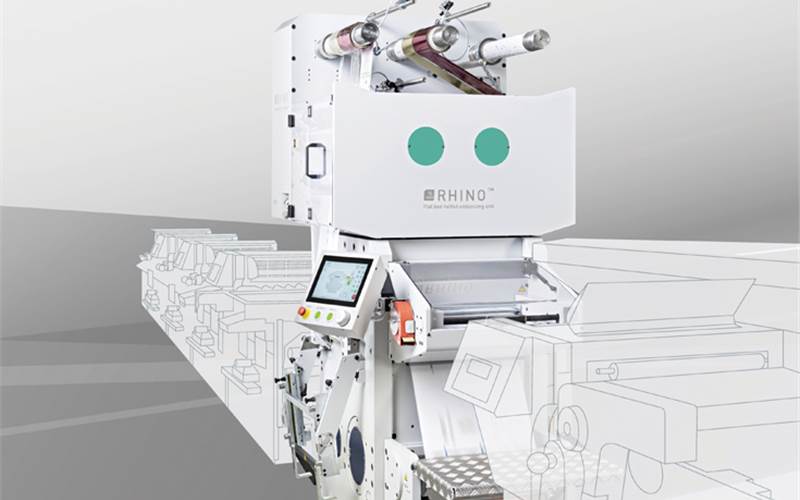

Product of the month: Rhino Series embossing system

In 2010, Pantec opened up inline label finishing and gave high-end printers an incredible productivity boost with the introduction of the Rhino flatbed embossing system. “Running with up to 30,000 strokes per hour operating inline to printing presses, there are 150 Rhino systems operating worldwide, including two in India,” Ranesh Bajaj, director at Vinsak, representative for Pantec in India, tells Noel D’Cunha

27 Jan 2020 | By PrintWeek Team

Q: What is the latest model name and number?

A: Rhino E is designed for short runs. The machine is recommended for label printers which are either specialised in short production runs or wish to include embellishment capabilities in their portfolio.

Q: What does the machine do?

A: Rhino E is a flat bed system for hotfoil, embossing and foiling in register.

Q: When was the machine launched?

A: Rhino E was launched in 2019 at Labelexpo Europe.

Q: Is it an upgrade of a previous model or a new product?

A: Rhino E upgrades the Rhino flatbed embossing system series with an edition specialised in short job applications.

Q: Which are the other higher or lower models of the machine, if it was an upgrade?

A: There are two models of the Rhino series – the Rhino S and Rhino E. The Rhino S is best suited for label printers which are dedicated to the production of impeccable embellished labels. It combines refined embellishment technologies with a performance that meets the high speed requirements of modern printing machines.

The Rhino E is recommended for printers which are either specialised in short production runs or wish to include embellishment capabilities in their portfolio. Beside, offering all the advantages of the well established Rhino technology, this model is also designed for frequent job changes.

Q: How does the machine work?

A: Rhino is a flat bed embossing system with a 90° rotatable foil head to operate either in web direction or across the web. The machine is equipped with an independent operating web dancer system to provide easy integration to any printing press or converting system.

Q: What are the key features of the machine? (Please give at least three-five features that will benefit the converters)

A: Multistroke (multiple foils and embossing in one tool) and placement of holograms in register open up outstanding design opportunities. Additionally, the robust machine design allows micro/nano embossing and high crisp relief. It is made for efficient running.

The fast foil change system, the Pantec shimming job saver plate and the job data storage are all designed to minimise changeover time. These unique features are particularly helpful for repeating jobs of which most can be set up in eight to 12 minutes.

Q: What is the USP of the machine?

A: Rhino allows printers to provide outstanding labels for brand owners to win the battle on the shelf – at only little extra cost.

Q: How easy is it to use?

A: An intuitive, user-friendly HMI makes it easier for the operator to run Rhino. Its operating system is designed to support daily operation.

Q: How much does it cost?

A: Prices are given on request and depend on the various options.

SPECIFICATIONS (Rhino S | Rhino E)

- Number of strokes max.: 30´000 | 18´000

- Mechanical speed, m/min: 150 | 85

- Pressure control: Electronic

- # of electrical heating zones, max. temp: 6/180 °C | 2/150°C

- Substrates - both models : PS-Labels, paper, plastic

- Rhino S 510: additionally carton

Contact details

Neeraj Sharma/ Mohan Pailwan

Exe_dir@creedemail.com/ gm_mc@creedemail.com

+91 9811043825 / +919930806950

See All

See All