Product of the month: Edale FL5

With two installations in India, this modular flexo press with flatbed die-cutter enables single-pass carton making, says Amitabh Luthra, managing director at Printers Supply Co, Edale’s Indian representative Indian representative

18 Jan 2019 | By Rushikesh Aravkar

What does it do?

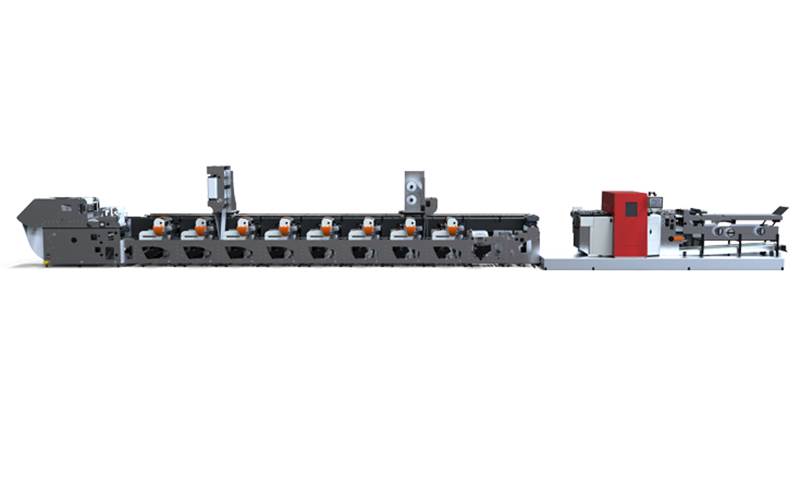

The FL5 is a flexographic printing press with flatbed die-cutter that enables the user to produce highly embellished cartons in a single pass. This brings in many benefits for a packaging converter. One, the work-in-progress material lying on the shopfloor is minimal. Also, since it is a single-pass operation the manpower requirement, electricity requirement and capital investment is low.

How does it work?

The press takes all the principles of label production and gives this flexibility to carton makers. The FL5 can handle substrates from 12-micron to 600-micron. It is modular in design and can be configured to any customer requirements. The FL5 is designed for cartons so unlike many label presses that claim to be carton presses it has large diameter rollers, a 1.5-metre unwind and uniquely can have a flatbed die-cutter in line. This allows many processes such as reverse print, foiling, cast and cure, lamination, die-cutting and stripping to be carried out in a single pass.

When was it launched and what market is it aimed at?

The FL5 with flatbed die-cutter has been around for nearly 10 years, however with the advancements in plate technology it has been a serious alternative to the traditional offset carton printing process. It is aimed at the low- to medium-sized run length carton segment. This is an ideal machine for anyone who aims to make an entry into the carton production market and also for anyone looking at expansion to already established offset printing operations.

What’s the USP?

The range of substrates and level of automation allow complete flexibility. From thin film to carton board all products can be run, which makes it an ideal press for label producers looking at the carton market and vice-versa.

What support is available?

Every Edale press allows for remote connection from the Edale factory allowing for quick and efficient diagnostics of most problems. As all Edale presses are servo driven there is a real benefit to the customer. Also, earlier this year, Edale has recruited and deployed a service engineer for India.

How easy is it to use?

The FL5 comes with five motors on each print station and full register as standard. This allows for storage of all jobs so set-up time and waste are much reduced. Edale develops all electrical and mechanical parts and software in-house and has been at the forefront of automation for the past five years. The addition of the Edale AiiR (autonomous inking, impression and register) system makes it the easiest press to operate in the market today. Also, changeover times are fast and efficient allowing for many jobs to be run per day.

Who’s using it?

There are a number of installations all around the world and two of these in India at Itek Packz, Bengaluru and NAP Printers, Kolkata.

How much does it cost?

This depends on a number of considerations such as width, number of print stations etc. One thing is for sure it is very cost effective compared to traditional carton manufacture methods.

Specifications

Size range: Upto a maximum web width of 570mm and print width of 550mm

Substrates: 12-micron to 600-micron

Contact: darren.pickford@edale.com, amitabh@printersuppliers.com

See All

See All