Orient Pack-N-Print doubles production after investing in Heidelberg presses

Indore-based Orient Pack-N-Print has bolstered its print production capacity after it added three new Heidelberg presses in the last three years.

15 Oct 2019 | By PrintWeek India

The first of the three, a Heidelberg Speedmaster SX 102 two-colour press with perfector was installed in 2016. In 2018, the company added, an SX 74 two-colour with perfector and an SX 102, a two-colour with perfector press.

This took the total number of Heidelberg presses from single-colour to perfectors to six-colour, to ten.

The Indore-based company operates in two verticals, one leaflet production, which comprises 75% of its work and second cartons which is 25%, for local industries and pharma clients. The company also produces mitigation guides according to customer requirement.

Vivek Badjatya, director, Orient Pack-N-Print, said, there are two reasons for the Heidelberg investment. “Some of the presses we were using were getting outdated. They were single-colour machines. There was a need for us to stay updated in the market. Second, our company produces leaflets with lightweight paper, between 30-40gsm. The demand has been on the rise, and these presses with speeds of up to 14,000 sph have enabled us to double our capacity.”

The company has been producing 36-37 million impressions (3.7 crore sheets) on each of the three new presses in a year. “The makeready is quick and perfect registration has resulted in fewer wastages, which results in savings,” said Badjatya.

Orient has been a Heidelberg loyalist, used its presses for more than 30 years. So much so, the company only has Heidelberg presses on its premises. “We invested in Heidelberg when no one in Indore understood those machines,” said Badjatya.

“Buying a brand new Heidelberg is a costly affair, but at the end of the day when we compare it three years down the line, it has matched he output to profit ratio, when compared to the older machine,” he said.

The company is equipped with multiple post-press machines which helps in catering to different sectors in the market.

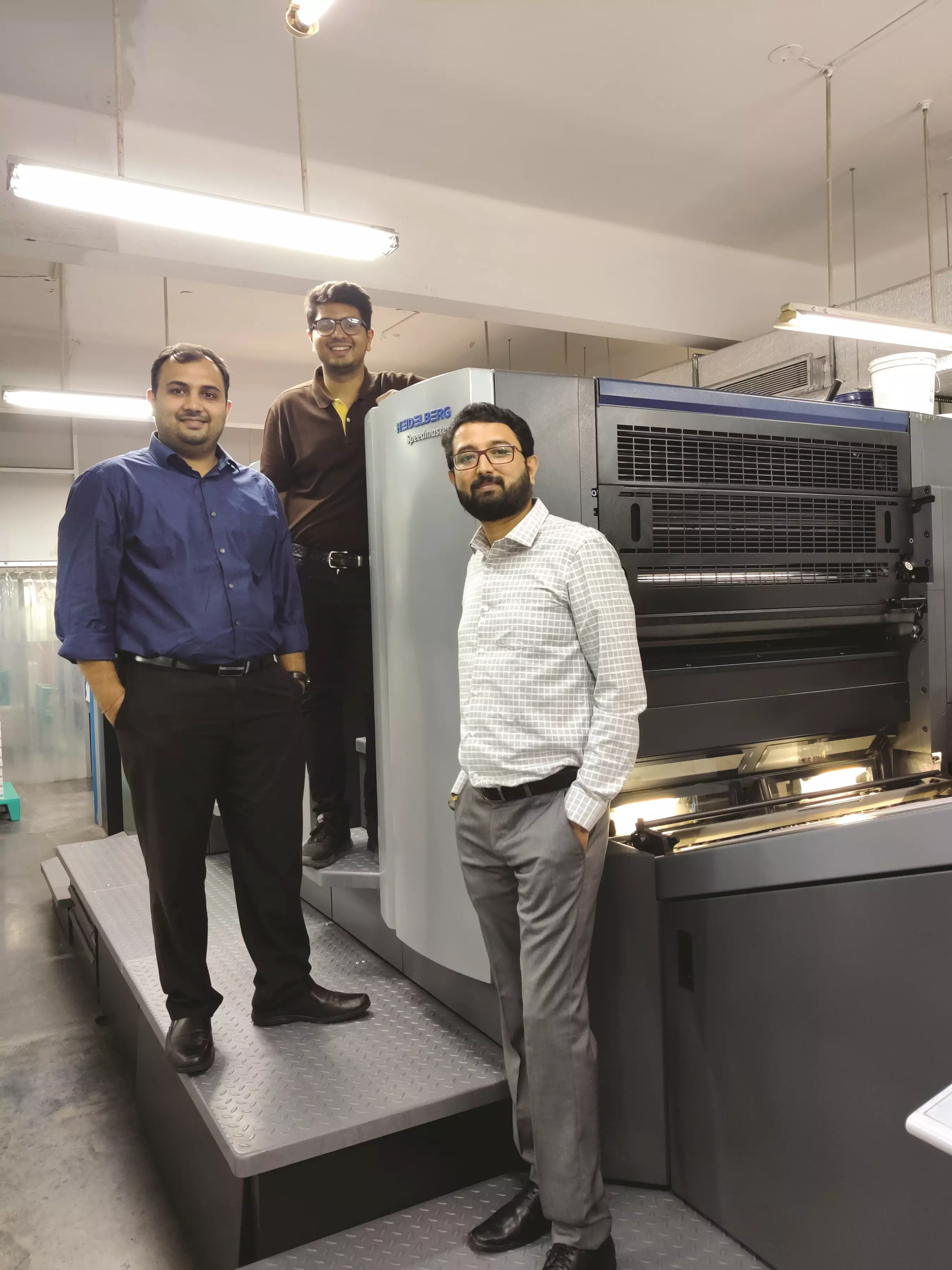

Besides, Badjatya, the family-owned company is managed by a managing committee comprising of Premchand Badjatya, Hemant Badjatya, Sharad Jain and Arvind Badjatya. Konark Badjatya is the plant head, while Purusharth Badjatya looks after quality and development.

The company employs 175 staff with some working for 25 years. The operators are now well-versed with the functioning of the Heidelberg presses. “All the operators have been trained in-house according to a certain standard set by the Orient management.

Going ahead, the company is planning to venture into different areas of pharma packaging. It will set up a new plant for this purpose. “The present packaging set-up caters to jobs like beedi and agarbatti boxes. It is not up to pharma packaging standards. We will dismantle the plant and build a new one which meets the pharma packaging norms,” concluded Badjatya.

Why Heidelberg perfecting presses?

Why Heidelberg perfecting presses?

According to Peter Rego, business head for sales at Heidelberg India, both the SX 74 installed at Orient, are with perfecting facility, for quicker production in one pass productivity. “Any job requiring front and back printing is printed in a single pass on perfecting. The new perfectors, unlike the old ones, can be switched between straight to perfecting at a touch of button. With new improved feeder and delivery we can run papers as low as 28gsm comfortably on our perfectors, a true USP compared to others, which is extremely suitable for Orient.”

On the technical advantages, Viraj Damle, regional sales manager (West) of Heidelberg India, added, “A true hybrid, the Speedmaster SX 74 combines the technology of the XL class with tried-and-tested stability of the SM platform. Equipped with production speeds of up to 15,000 sheets per hour and shorter make-readies and throughput times. A neat fit for mid-size format jobs, the Speedmaster SX 74 also handles a wide spectrum of substrates from thin sheets to boards, ranging in thickness between 0.03mm and 0.6mm.”

Rego added, “On the other hand, the Speedmaster SX 102 is a cost-efficient press in 70 X 100 format. Highly automated and intelligent processes render the equipment user-friendly, while minimising make-ready times, energy consumption and paper wastage. The unique perfecting and sheet travel technologies ensure consistent and high quality print on both sides, even with very thin substrates. After prudently going through Orient’s print jobs, we supplied them our SX presses.”

See All

See All