Madurai’s Sree Vinayaga Screens bets on packaging - The Noel D'Cunha Sunday Column

For Sree Vinayaga Screens- the 42-year-old offset firm in Tamil Nadu, the expansion to packaging was a foregone conclusion. But the highlight is: the company's diversification in the tumultuous pandemic year.

L Ramanathan, the company’s managing director spoke to PrintWeek about how to plan prudently in these pandemic times

20 Dec 2020 | By Noel D'Cunha

Brave to have diversified into packaging in 2020.

There is a famous English expression: When the going gets tough, the tough get going. This quote is apt for all entrepreneurs in 2020. We are doing well in printing and publication, so the packaging plunge was always in the scheme of things, and I believe in start small and grow big.

What kit have you invested in?

We started in the middle of 2019 with two new platen punching machine, a new Maxima automatic die-cutting machine and a used Bobst Amazon folder-gluer to start with. This was the best decision, mainly because from March regular printing jobs went to zero. It was the few packaging jobs which kept us running for three months.

You have attached a UV system to your Komori press? What's been the outcome?

In my view, investing in a UV system was a wise decision we took in the last PrintPack. To be frank, then there was a strict ban on usage of plastics in TamilNadu, so we wanted to convert all our lamination jobs to drip off and coating and did not want to invest in a new machine. But it turned out to be great as we started to use it at full capacity.

How did you retro-fit this system?

I am very proud to tell you that we are the first to introduce UV in the Madurai market. Yes, retrofitting in a running machine with IR and coater already was a scary thing, but it was an experienced team of engineers and a team from China came over and stayed with us for a week and trained us in all aspects. It was tough and challenging initially, but eventually, we have learnt the skillset and have the confidence to invest in a full UV machine soon.

Mono cartons in India are generally higher-end packaging, which demands superior print quality.

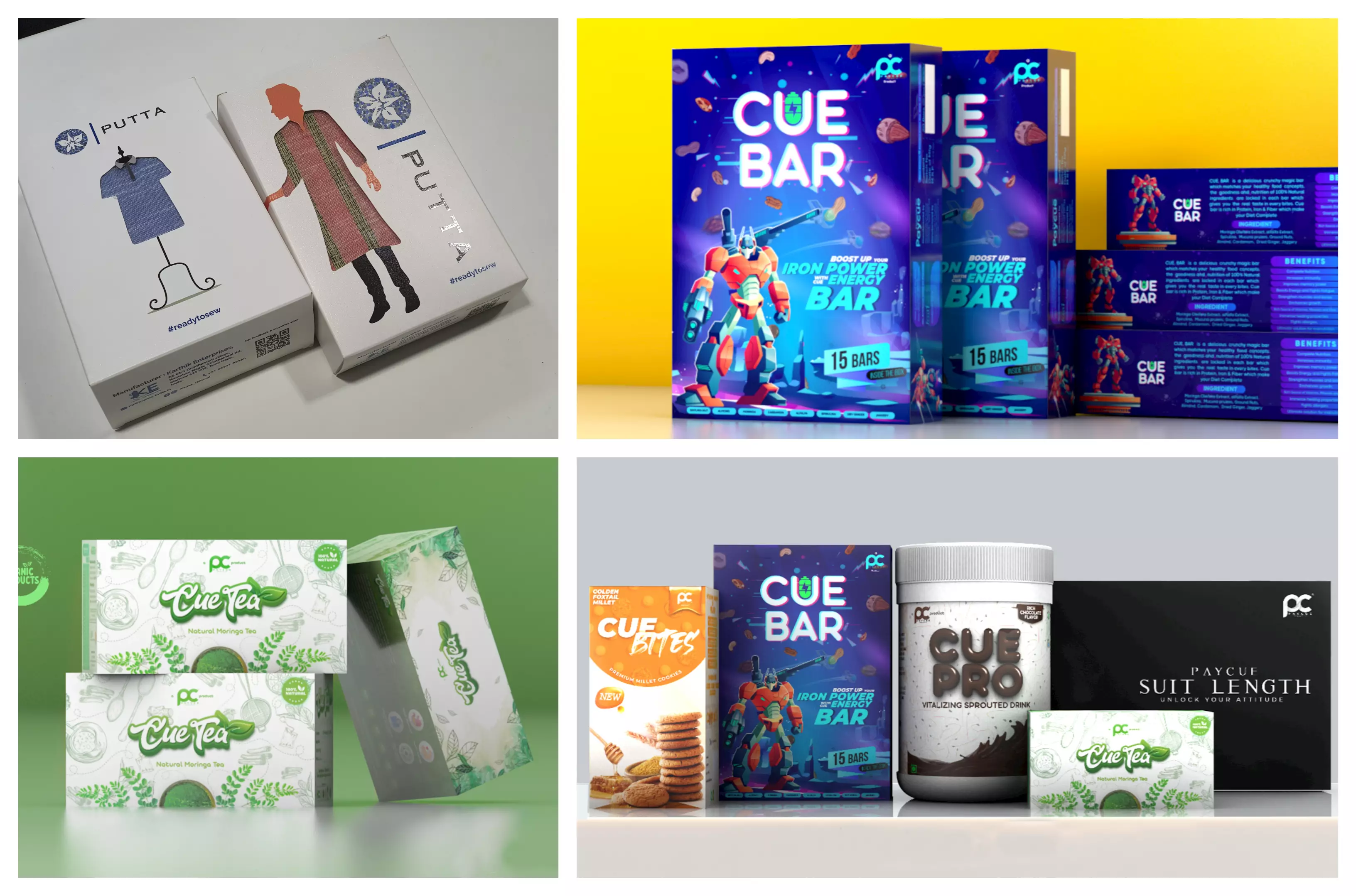

I don’t fully agree with this statement- High-end mono cartons as we see in supermarkets are a small part of this high volume segment. I believe there is a gap, a lot of product manufacturers, who do decent quantity don’t get a good quality packaging partner or they are not aware of the latest packaging trends. I’m mainly focusing on that market where I can give them a solution. The plan is to provide high-end packaging for a smaller quantity in tier two and three cities. This way we are confident to cater to the giants.

How have you prepared for this "fussy" market?

Yes, to answer your question, we are prepared for the so-called fussy market. We all in our team had taken an oath to continuous learning in any and every possible situation and this market can be handled if we give attention to details. The only way to sustain and survive packaging is the attention to the details which we are working on.

You are focusing on MetPet + drip off cartons?

Learning UV was definitely tough in the initial stages. Thanks to my institute PVG in Pune, my final year project was on offset UV printing. This was in 2005 when UV was just new and not very popular. The project was basically a study of print parameters of UV inks on various substrates. The project report was dusted out and was of great use to get me started.

How was the learning curve for you?

Trust me the technology has several dynamic behavioural quirks, and one can master it only with practice. It’s not just about printing; the eye-catching output of the product truly depends on the pre-press work done behind the scene. I always remember and thank pre-press guru Ashok Nerker, who thought me the basics. The white separation and the drip-off separation has to be appropriate for a great look.

Do you see the packaging print market growth in Tamil Nadu?

Oh, most definitely! It is growing and will grow. One good thing about Covid-19 is that it has created a lot of new entrepreneurs and start-ups. Many want to manufacture their products and sell it online. So there is a good requirement of short-run cartons and it is only increasing by the day.

What kind of innovations excites you?

I’m very fascinated about custom printed cartons, short-run corrugated cartons, PP cartons etc., and what excites me more is making them available to young small-time manufacturers.

How has the coronavirus pandemic impacted Madurai?

Honestly, the impact is equal and challenging in all parts of the country. The offset and digital printing segment have been hard hit by this pandemic. Many small printing presses suffered - and are suffering. But one good thing which happened during this pandemic is many small and medium companies who had offices in Chennai and Bengaluru have shifted to tier-two cities like Madurai as the cost of rent and workforce is cheap and more efficient.

Which segments and industry verticals are you bullish about?

I think things are getting back on track and we are waiting for a great 2021. And yes, I would say food and pharma industry are at their peak now.

L Ramanathan: The litho man

L Ramanathan and his wife, Kalyani, a print technologist from PVG

I am a printing engineer and being trained in all forms of pre-press and printing. I would call litho my favourite as you put it. I find the mixing plays a crucial role in everything. Less the water more the thrill (in printing result). What I have learnt in these 10 years is that small and medium scale printers are not giving much importance to maintenance in terms of time and money. Trust me that’s my learning: regular, systematic, timely maintenance is more profitable in the long term.

See All

See All