Kraft price hike dents brown boxes

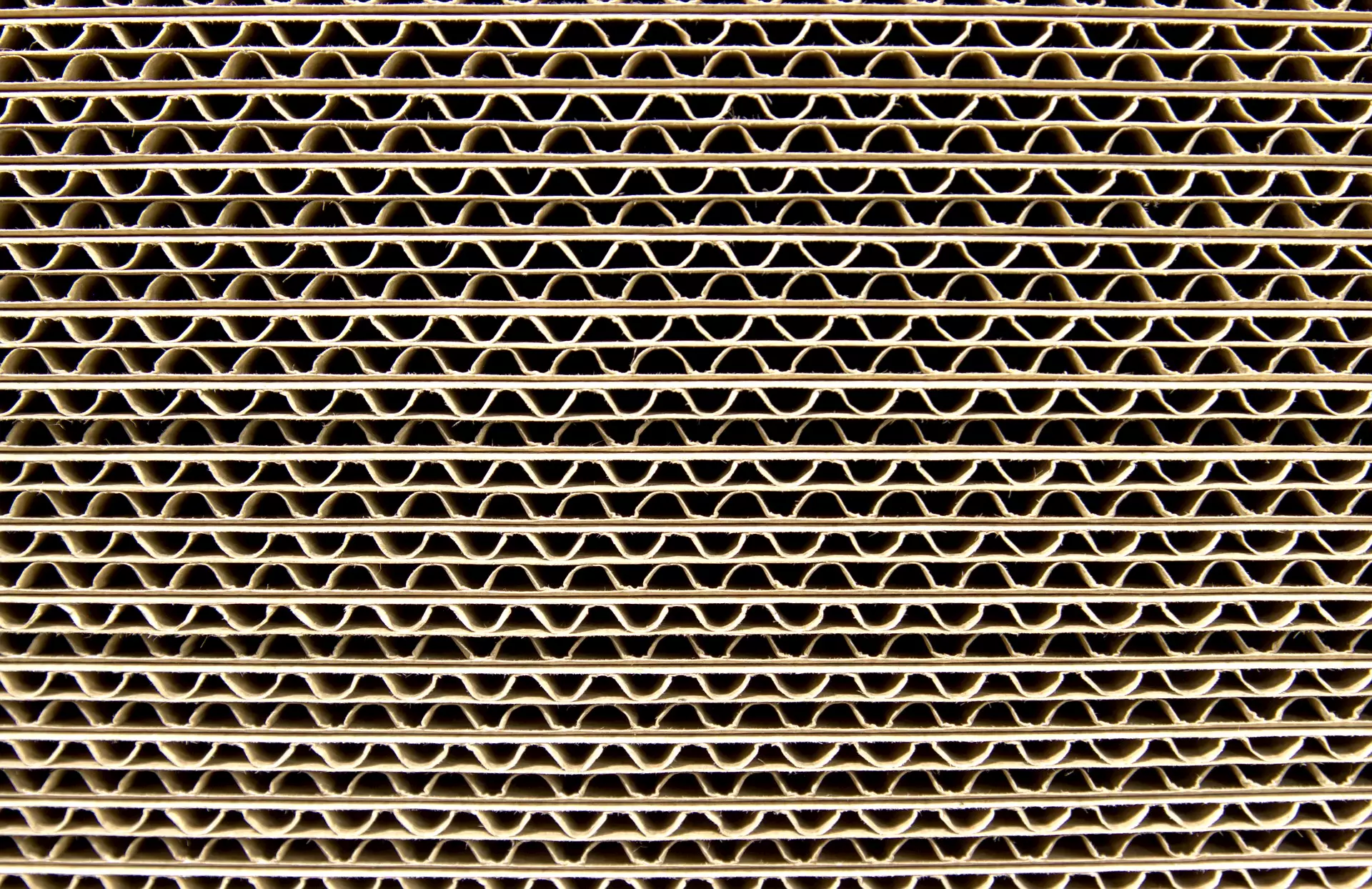

The packaging industry is facing substantial cost and availability headwinds across multiple raw material categories. The rise in kraft paper prices has been severe

06 Mar 2021 | By Sriraam Selvam

The warning bells started ringing in October 2020. Packaging and delivery specialists had urged businesses to plan their needs in advance and seek alternatives as cardboard box supply continued to be impacted.

Today, corrugated box manufacturing has been severely affected by the paper price crisis. According to the Indore Paper's Traders Association, the prices of kraft paper have increased by around 40-50 per cent. This has impacted board prices by 20-25 per cent in the past ten months.

The PrintWeek-DIC webinar on 23 February 2021 said that Covid-19 has brought about an acceleration in the transition to online buying. This too has had a significant impact on the use of packaging. Industry leaders said a 45% rise in prices of kraft paper has made the end product expensive by over 10 per cent in almost all categories of boxes.

The cardboard shortage could lead to delays in deliveries, damaged parcels and increased charges

The recycling chains are getting affected. This is causing a delay in obtaining the recycled pulp fibres that are used to make packages and corrugated boards. This and other factors hitting the supply chain are combining to create the current shortage in packaging material. Kirit Modi of ICCMA has said, the situation is leaving many businesses with a logistical problem. He said, "We are holding back-to-back meetings among all our stakeholders as there is a massive price increase ranging around 35% or so."

This spurt, especially in the cost of kraft paper has increased the manufacturing cost of corrugated boxes which is deployed for packaging and transporting goods. Sanjeev Sureka, the president of Madhya Pradesh Corrugated Box Manufacturers’ Association, said, "The cost of raw material, be it paper, starch or other items have risen. This has lifted the cost of manufacturing. We are contemplating an increase in the prices of corrugated boxes by 15 per cent."

The cost of kraft paper has increased the manufacturing cost of corrugated boxes

A closed-door webinar discussion that the WhatPackaging? team attended had industry leaders stating, the situation was grim - what with the prices of corrugated boxes up by 25 per cent since late last year. A second round of hike is anticipated in a couple of weeks.

Rajendra Mittal, the president of the Indore Paper's Traders Association, said, "Supplies from mills have declined sharply. We are receiving less than half of the ordered materials from mills. A drop in availability of pulp and freight has scaled up prices."

Meanwhile, the price hike continues unabated. Sappi Europe will increase prices of all of its packaging and speciality paper grades by 7%-11%, valid for deliveries from 1 April 2021. In a statement, the paper manufacturer said: “Sharply rising input costs, particularly relevant to pulp and energy in combination with very high freight rates due to global logistic constraints make price increases unavoidable.

Kraft paper price hike has impacted board prices by 20-25 per cent in the past ten months

Separately, Flint Group said it intends to increase the prices of its ink and coating products, also effective as of 1 April 2021, though specifics on the increases were not available at the time of writing. The company said it is facing “an extraordinarily turbulent set of supply chain conditions, exacerbated by the global pandemic” and that its costs are increasing and supply is tightening across almost all procurement categories.

The WhatPackaging? team spoke to a brand manager of an FMCG major, she said she was worried that "the cardboard shortage could lead to delays in deliveries, damaged parcels and increased charges." Industry leaders are advocating collaboration to cope with the present shortage in supply and future changes like we’ve never seen before. The mantra is: "Get advice, take long term action and talk to your packaging supplier now.”

See All

See All