Know thyself : Fujifilm’s message to print-land - The Noel D'Cunha Sunday Column

The business is roughly at 70% levels of pre-Covid-19 levels, says Kentaro Imafuku, head of department of the graphic arts business at Fujifilm India, during an interview with PrintWeek

Read more

11 Jul 2021 | By Noel D'Cunha

PrintWeek: How do you plan to offset the drop in sales of commercial printers last year - which is continuing into the Q1 of current FY?

Kentaro Imafuku: Basically two ways. One by maximising existing products sales in the package printer segment where job volume is stable even under Covid time.

PW: … And two?

KI: By launching new digital printing solutions mainly to the commercial printer segment where short-run needs are getting higher due to job volume drop because of Covid-19 crisis.

PW: The Covid situation looks grim. Has print-land painted itself into a corner?

KI: I don’t think so. Print as an industry is similar to many other traditional industries.

PW: How do you view the steady devaluation of print?

KI: There will always be lighthouse players who will spearhead innovation, value addition and create a road map for the future. Over the years their value has only increased. Having said so, for the industry as a whole, the drop in print volumes have been offset by a need to increase in value. Each of us in the value chain have to find a sweet spot.

PW: We were studying the balance sheet of the biggies like P&G and Unilever. One big trend we noticed is, marketing being downgraded to an ancillary function rather than a strategic function. Under such circumstances should the graphic arts industry modify its strategy?

KI: The pressure on “marketing” as a function is more to do with rapid technological advancements with tools such as artificial intelligence (AI) and machine learning (ML). I feel that while the marketing function still remains as strategic as it was before, the way it is done has changed with these set of advanced tools.

Graphic arts industry needs to modify its strategy according to this change by building in system and process intelligence. That area requires adoption of technology, integration, cross-coordination of hardware and software from multiple vendors and finally seamless implementation.

PW: Today a Fujifilm client needs a partner who can think strategically and see the big picture. As a print-partner do you understand the challenges your client is facing?

KI: To understand a customer’s need and to pass the feedback to our product planning is the core reason of our existence as a manufacturer of repute. Our history is replete with continuous innovation in printing technology to meet our customer’s needs in the graphic arts industry.

PW: In this Covid era, have you been able to help identify strategies for new or faster growth?

KI: Today, the industry is reeling under the impact of Covid. The main challenges are: job volume has dropped or fluctuated, it gets more difficult to keep factory operators, and cash flow management by reducing inventory. One key strategy to overcome these challenges is – automation of the printing process.

We are providing process automation to customers with our products such as workflow software, processless offset plates, inkjet systems or Xerography digital printing press. And to top it all, a combination of this story that has the ability to provide process intelligence which I mentioned above.

Marketwatch with Fujifilm

Historically Fujifilm has its commitment to the graphic arts industry that predominantly includes the commercial printers. Within them there are the packaging players, publishers and general commercial printers which are Fujifilm’s main customers. Over the last many years, through technological solutions in the wide-format UV inkjet, the company successfully forayed into the signage space as well.

Fujifilm is supplying analogue and digital solutions to quite a few customers through its partners. As the industry grapples with post pandemic impact, the market for short-run, personalisation, quick turnarounds is positively impacting the digital domain as the Japanese manufacturer continues to bring efficiencies in its analog business as well.

PW: In the pre-pandemic months, we visited five Acuity customer sites in India – and spent considerable time at the factories. We felt there is a huge knowledge gap between the high-end capabilities of the UV flatbeds - and the low technology quotient among print buyers.

KI: There can be world-class technology available on hand but we also need the expertise and ability to use them and make the best out of it. In some cases, it might be true as you mention, however, there is no harm in acknowledging that in some other cases the customers also give us an insight on how best to use a system.

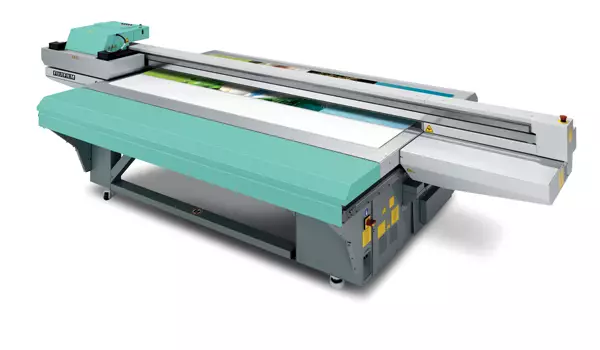

PW: You have unveiled your new line of Acuity printers. How will it help the wide-format print firm add value - and solve the creativity problem?

KI: We have launched the new line of products (Acuity Prime, Acuity Ultra R2 and Acuity B1). These are combination of flatbeds, roll-to-roll and B1 wide-format systems. These are systems that can handle rigid and flexible media. These are benchmark platform for versatile print production, which provide a wide range of high-value print. There are unique features in each product that helps expand the printer’s creative options providing him an excellent return-on-investment (ROI).

PW: The linear series way everything functions, means the wide-format print department is the last to be engaged in the process. This means the good ideas are never coming from the graphic arts segment. Can a manufacturer like Fujifilm help in reframing / recontextualising / reconceptualising the print debate?

KI: Not sure if this linearity is true for all companies. You see, I am aware of some FMCG companies that have involved their print service providers during NPD (new product development) and concept design. It is also a function of the ability of the print service provider (PSP) to influence changes. Same is true for marketing communications as well.

Sometimes the best way of information dissemination comes from the person who prints

them. Since he works for various companies and industry and knows how best things can be done. Agile companies and progressive suppliers keep this channel of communication on.

PW: What is the latest on Fujifilm’s strategic tie-up with Xerox?

KI: Although our agreement with Xerox has expired, they have been our important business partner and can be in future too.

PW: Will Fujifilm continue to be the OEM for Xerox?

KI: We are not in a position to comment on their OEM procurement policy.

PW: So, who sells what products and under which brand name?

KI: We are holistically committed to the graphic arts industry by providing a wider range of solutions, one of which is Xerography POD.

PW: What has been the response to the Virtual Exhibit 2021?

KI: The 3D Virtual exhibition has been a simulated event in which Fujifilm showcased a plethora of products related to various segments of printing industry. From processless plates in general commercial printing, to digital toner colour and monochrome solutions in the POD space to the flagship and the new JetPress 750 S B2 inkjet technology that caters to a wide segment of the market. We also have unveiled a new line of flexible packaging and label printing machine and finally new products in industrial and signage space.

The navigation within the site was very user-friendly and customers could pick and choose which technology they want to have a look and feel of. There were product videos, simulations, descriptions as if you were attending a real physical event.

PW: Which knowledge sessions were a must attend?

KI: The live seminar on 7 July titled – Print More Deliver More – was interesting. The session on – Future of Digital Flexible Packaging – on 25 June was also very insightful. PrintWeek readers can go on the exhibition and check the recording. Another one that I would point out was a session by Marco Boer on – Challenges and Opportunities for the Commercial Printers Post Covid. We have had thousands of people visit the virtual exhibition and a large proportion were from India.\

PW: Fujifilm is rebranding itself in the digital space, what is the trickledown effect for a market like India?

KI: It’s not like we are rebranding ourselves. Least to mention rebranding in digital space. We have been always a partner and solution provider to graphic arts industry with highest quality and wider range of products from analogue to digital. However, I think, only highest quality is not enough in India.

We need to Indianise our solution so that we can deliver it to the customers here. And so, it is most important for us, to hear the customer’s voice and partner’s voice to market our new solutions. We look forward to it.

PW: Targets for the next 12 months?

KI: Establishing a unique position by full-scale introduction of processless offset plates and inkjet and xerography digital press for the Indian graphic arts industry.

About new product announcement at Fujifilm Virtual Event

- Commercial Printing: JetPress 750S (B2 size fastest cut-sheet inkjet press).

- Labels and Packaging: JetPress FP790, a web-based digital flexible packaging machine.

- Short Run Digital Printing: Revoria which are toner-based digital colour and digital mono machines.

- Signage and Industrial Production: Acuity Prime (flatBed) and Acuity Ultra 2 (3-mtr wide roll-to-roll).

- Plates: Offset plates : processless plates ZX with faster output, higher durability, better visibility and robust scratch-resistant.

See All

See All