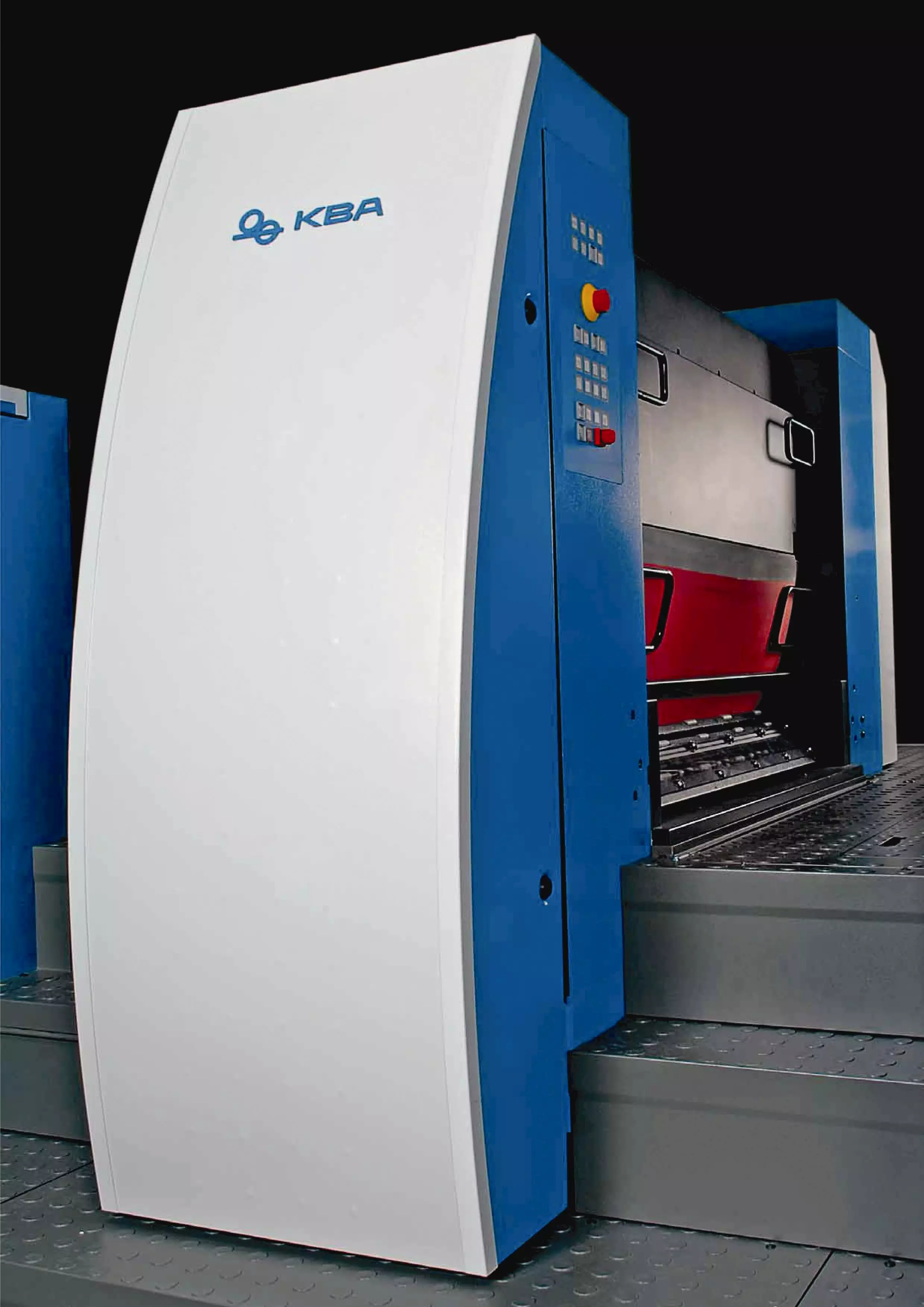

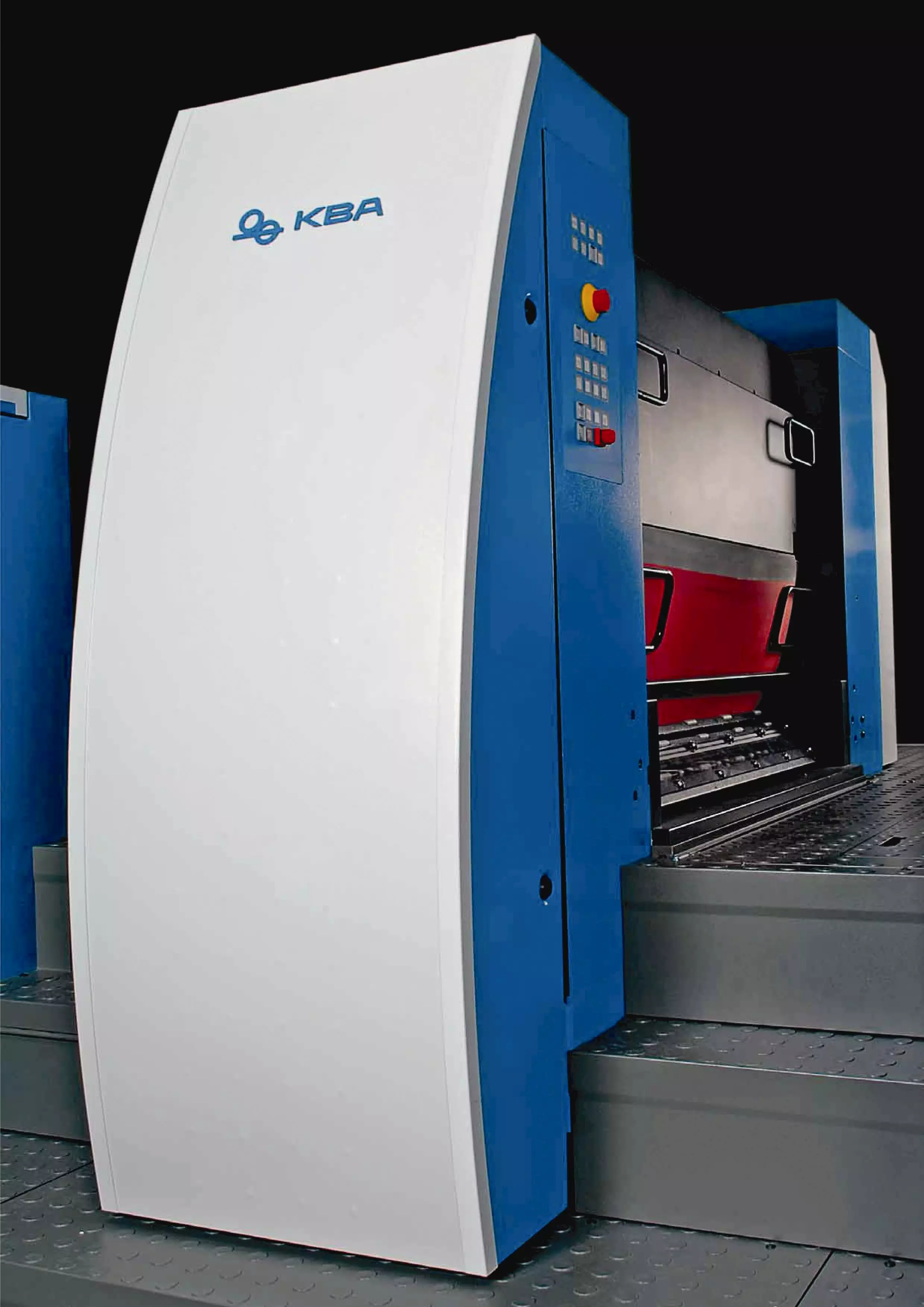

8 May, 2015. A gala event in Mumbai. An audience of 150 brand owners. There is KBA. And there is carton packaging major, Parksons Packaging. The event: the launch of inline cold-foiling technology in India. The star: the KBA Rapida 106 eight colour press at Parksons’ Pantnagar plant.

With this installation and several in pipeline, Aditya Surana the boss at Indo Polygraph claims to be having “one of the best years” for KBA in India. The statistics speaks for itself. According to him, KBA has shipped a total of six machines up to May 2015 with each of these machines being seven or above colours, fully loaded and highly configured. KBA is expecting at least five more machines to come in 2015.

Anand Srinivasan of PrintWeek India gets a lowdown on the formulae that made KBA to be a success in the UV market and what will happen on the KBA front in the next six months.

Indo Polygraph boss, Aditya Surana is pleased. His decades old agency which was looked upon as a vendor to the unorganised sector has made a leap of faith. Surana attributes this to KBA on the shopfloor of multi-locational firms like Parksons, TCPL, ITC. He says, “In the two years, we had a press in TCPL’s Haridwar plant, Silvassa plant and one at its Guwahati plant, one more press coming at Haridwar plant. Adding to this, we have machines at Parksons’ Rudrapur plant, Daman and Chakan plant and at ITC’s Chennai and Haridwar plant.” This was because of the orders for sheetfed special presses.

KBA is scoring in the 28x40inch format which caters to the packaging sector. “The presses at these organised setups are as loaded as any European or American setups. These are real top-end with zero compromise in configuration,” says Surana.

Essentially one trend that is happening in India, according to Surana is that less of six-colour and more of seven-colour machines being bought. “This is happening not only with the organised sectors but also with B-segments. A good example would be the third generation Nextgen Printers from Kolkata which has got in a new seven-colour KBA.”

Compared with the previous year, when restructuring expenses of over €155.2m (Rs 1100-crore) strained its operating result and delivered an operating loss of €130.7m (Rs 926-crore), in 2014 both KBA’s sheetfed offset segment and the web and special press division posted an operating profit.

Litho strikes back

Litho strikes back

At PrintPack, the Ryobis and Komoris talked the talk. Heidelberg has come out of the red. So are we seeing a rise in the sheetfed sales as a whole?

Dietmar Heyduck, senior vice president sales at KBA, who was in Mumbai for the Parksons event says, “The sheetfed offset segment generated profit.” He attributed the rising sales of sheetfed offset presses to business in the packaging segment and book printing. Also, he was eyeing metal-decorating systems.

He adds,“It’s a question of cycle. We all have a dip and then we come out. Generally, the trend was that a year before Drupa was a dull year. But this time, the companies don’t want to have a dip. They are keen to share what is being launched at Drupa and what technology is going to stay.” This has stirred the sheetfed market.

He says, “This is why the positive performance of the KBA in India in 2015 has been particularly pleasing as order intake here profited from KBA’s strong position in folding carton and metal decorating, and lifted slightly, bucking the industry trend.”

KBA’s management board has identified growth opportunities in digital and packaging printing, and aims to focus more on applications with challenging materials and large substrate widths.

In real terms, this translates to 5500 tonnes of paper being converted in North India. “By end of this year, Parksons and TCPL, will be having four lines. And they are highly automated presses. There is not a single unit in the whole of North India which has four-lines,” points out Surana.

Trends in Litho

One tech trend we see is that of applications migrating to other technologies. Surana says, “A trend we find is, publishers are becoming printers. S Chand is a good example. Also, all big publishers have in house printing facility, now.”

Surana adds, “On the packaging side, food packaging is the future. Pharma packaging is at an all-time high; plus there is liquor packaging. When we talk of KBA presses in the packaging industry, most of them being revved to do long runs, with some amount of presses also being used for short-runs. But there are packaging companies which work on the seven make-readies a day business model, too.

At the end of the day, Surana points out, a print professional, needs a higher amount of sheets on pallets in a day with faster makereadies and UV curing at a higher speed. Since KBA has an in-house UV curing drying system, it has an edge over the big manufacturers.

Surana adds, “It’s going to be a record 2015-16 for us. We are seeing another six or seven fully loaded brand new presses from the KBA stable within the next six months.”

And 2016 brings us to Drupa. KBA has said that it was working on “a raft of new developments” for Drupa 2016. We ask Aditya Surana for his insider view. He replies, “It’s going to be interesting. This is a clear message from KBA.”KBA and the pre-owned movement

Surana says, “What is happening on the pre-owned side is quite amazing. But what you have to understand is due to the world recession in 2006-07, many commercial printers were affected. This did not affect the packaging players. As a result, the availability of a second-hand UV press was rare and to add to the fact that no printer was desperate to sell their press.”

Since packaging is on the ascendancy, worldwide, there has been lot of developments and changes. If somebody wants to buy a new four-colour press, it doesn’t make any sense. There has not been much of automation increase if a printer buys a 2007 model as compared to a new model available. But if someone buys a 2010 UV press, there are a lot of notable changes as compared to 2015 UV press.

From the pre-owned side of KBA, availability of spare parts has not been a problem. “We have all the spare parts available for the machines for at least 20 years from the date of manufacture,” says Surana.

What makes it difficult for a pre-owned machine is the high counter plus high mileage as well as the appalling condition of an Indian machine. According to Surana, this is the reason, it is not easy to re-export a press out of India.

Speaking of how KBA has approached this situation, Surana says, “If KBA has to officially buy back the machine, an expert will come, evaluate the press and give a price.”

Surana reassures us when he says, “Fortunately, we feel all this is worth it because we are no longer into the simple four-colour press configurations. As an agency when you are selling a press with higher value, it is worth it. This is also the reason why we take so long to get aggressive in the commercial market. Because on one side, you have to be cost-effective. Howsoever there are the demands of a commercial printer for training, providing finance, buy back, plus service support.” Surana concludes, there can be “no compromise”.

10 SOUND BYTES

Asian domination

We see a major domination of Asian market. Hence tailor-made machines are provided in such cases. This would be mainly with lots of changes on the in-feeds and the number of units; along with tweaks in the configurations. Like KBA can offer the shaftless feeder concept. This enables the printer to get a precise in-feed. Because of this we can also run Indian boards at full speed.

Stand-alone installation since 2011

We had been installing presses earlier as well. Prior to that, we installed simple configurations. For example, when Parksons got their first UV press in 2005, there was complete intervention from KBA. They installed the press. They thought we were not competent enough and we were not. After that, there were not many machines per year. The numbers weren’t adding up. But things have changed with us, post 2012.

KBA and pre-press

We are converting pre-press data to ink zone data. Most of our presses are armed with the Densitronic Professional which offers online correction of ink and density. Also, we can integrate a system for spectrophotometric readings and correct it online. Customers like Parksons Packaging have an online PDF scanner which provides a report after every job.

Indo Polygraph biography

We have the technical support of more than 36 employees. We are responsible for complete installation and application. We are proud to say that, all these big machines that we are talking about, we install them ourselves.

Formal calculations for ROI

Although we do not have a benchmark analysis per se for the machine, we have a system in which we ask the customer the total make-readies he has, and then we can calculate and tell them if it is feasible to buy a particular option on the machine or not.

Indo Polygraph’s role

We aid with forecasting, product mix, cost-centres. We are getting more and more involved when it comes to protocol tests. We are supposed to provide the customers with onsite training. When any customer buys a machine, he has print jobs in mind which is a part of the acceptance criteria of speed. We take it to what we call the overall efficiency test and check for compatibility issues.

Level of maintenance

The level of maintaining a press in India has gone up. The perception that Indian machine are not well maintained, is going to go away. Customers are open. They are willing to experiment with consumables. What the consumers want are maximum number of UV-cured sheets on pallets every shift and are willing to extend us any kind of facility in order to obtain regular and uninterrupted high production outputs.

Variation in grammages, Indian boards and uncoated papers

Our customers send us their samples to be printed. We provide them with a link on which they upload their job. They specify what kind of board they want and we do trials on it. That’s where technology has taken a big leap. We are not facing any problems running Indian boards on our press at full speed.

Installations

We have KBA engineers for the first round of installation plus support for anything that is new.

The basic machine was installed by the Indian team. In addition, our team is getting trained not only from the mechanical and electronic aspects but also in the application aspect of it. With all these, we take pride in saying that, to install an eight-colour UV press with no intervention from Germany is a big step for us.

Press inspections

The system is in place. This means, the system starts blinking when there is an oil-change coming up. We have customers with whom we have AMCs. These customers insist upon monthly or quarterly maintenance. Within the warranty period, we are monitoring the machine every month and after that we work on an arrangement.

Litho strikes back

Litho strikes back

See All

See All