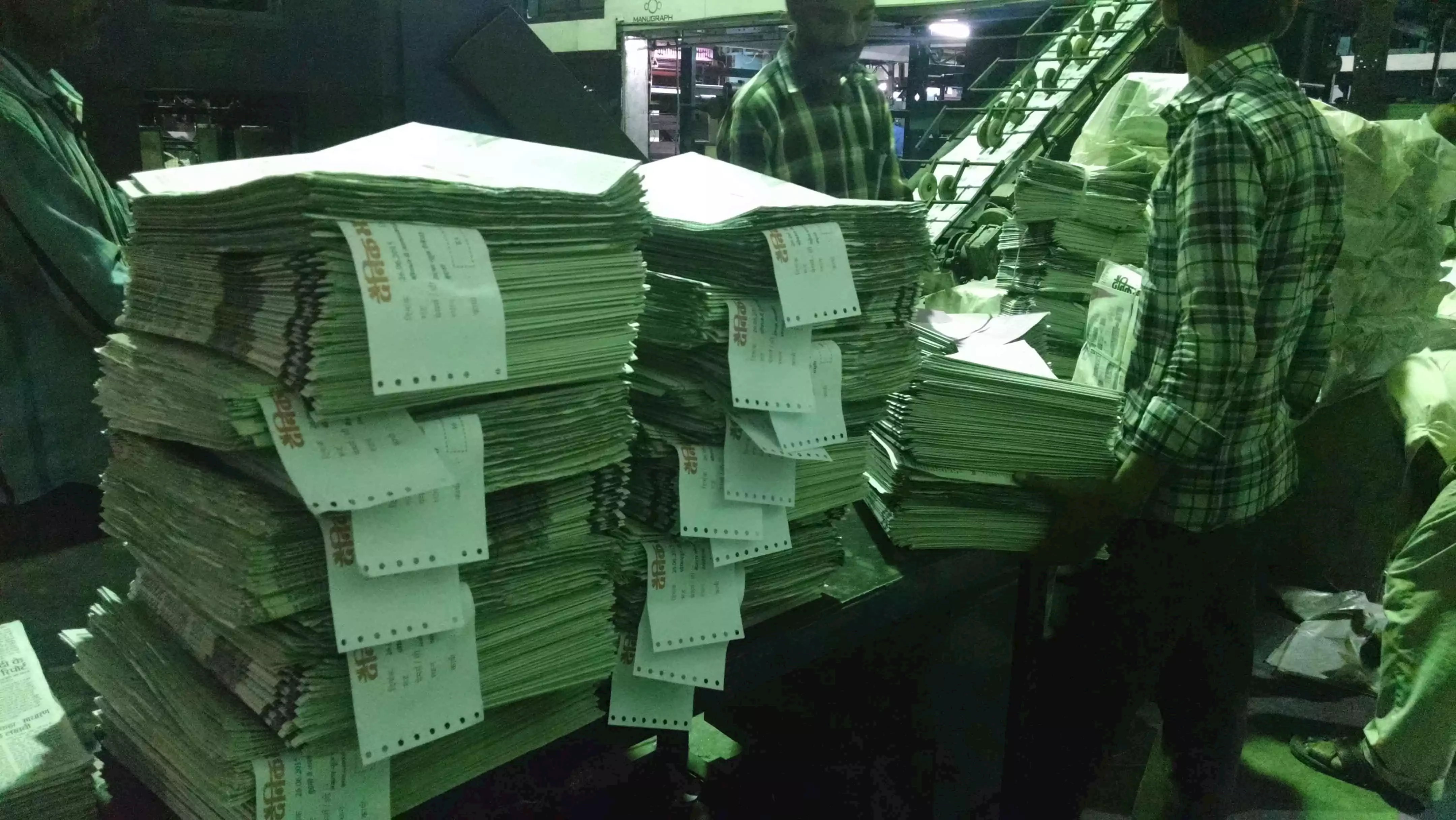

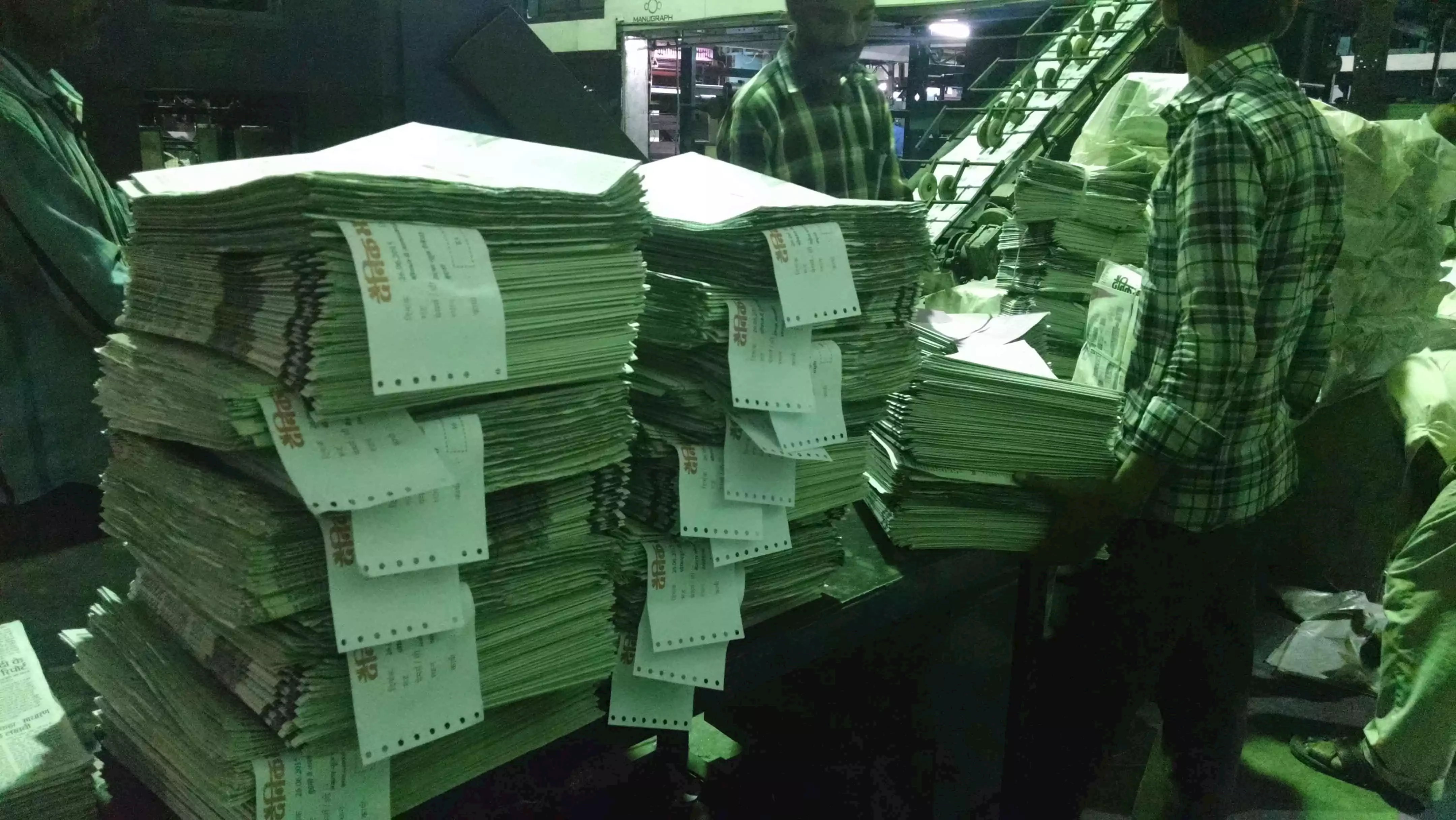

One nation, 14 states, 61 editions, one newspaper - Dainik Bhaskar. Mugdha Gangoli spends time on the shopfloor in Bhopal where the flagship Hindi newspaper made its humble beginnings

Started in the year 1958 by DB Corp, Dainik Bhaskar is one of the nation’s largest selling newspapers. With a total readership of 44-mn in four languages, the newspaper group is the largest print media group in the country.

Amid the silent roads and hushed surroundings of the Govindpura industrial area of Bhopal, stands tall the Dainik Bhaskar press. Upendra Singh, assistant general manager takes me on a tour through the plant built on an area of one-lakh sq/ft. Having spent more than a decade at the press, the place is no less than a home for the mechanical engineer, which is quite visible with the super clean premise. “Is it renovated recently?” I ask. “No,” says Singh, somewhat confused with my question.

The Indian press

The shopfloor at Dainik Bhaskar press deploys two Indian-make machines, Manugraph’s M360 and Hiline, which help Bhaskar cater to our country’s increasing Hindi literate population. While M360, installed in 2012, runs at a speed of 36,000 newspapers in an hour, with seven towers, seven autopasters, and one folder 222, Hiline (seven towers, seven autopasters, and one folder 232) produces 45,000 numbers an hour. This seven-tower press can print 28-pages at one single time. Hiline was installed in 2013.

A third machine has recently joined the Indian press army. The Ronald web offset (previously known as KK Printing), with a speed of 36,000 cph has been installed in the Bhopal unit which will commence its operation in August.

Hiline was first introduced to Bhaskar at Divya Bhaskar in its Ahmadabad edition, with one tower of Hiline and seven Y units. Thereafter, one of the most revolutionary configurations of Hiline was commissioned in DNA Mumbai – four lines of eight Hiline towers, folder and an overhead dryer.

DB proudly calls itself as the only press at that time to print the first sheet on glazed newsprint on a heatset and rest of the pages using coldset web offset process.

The press units in Indore, Jaipur and Ahmedabad houses KBA web offset press. The huge German-built has a potential to run at a speed of 80,000 copies per hour with automatic inking system.

The standard print cut-off of Hiline is 546mm as against the new M360 and Ronald with the new industry standard cut-off of 533mm. Singh reasons the changing cut-offs to the increasing cost of newsprint, which amounts to 60% of the entire production cost.

The Bhaskar diaries

With Bhopal, the city press unit also facilitates to the surrounding tier-II and tier-III towns and cities. The list includes Vidisha, Guna, Rajgarh, Raisen, Ashoknagar, Sehore and Vyabra. Dainik Bhaskar generates 3,40,000 copies per day, with 2,90,000 for the Bhopal edition and around 60,000 for the surrounding cities.

This giant number counts for a 24-page main newspaper and a 12-page daily, DB Star. The lazy Sunday sees a 28-page main issue with a six-page classified and five special four-page pullouts.

With an interesting tagline “Yeh Badal Dega Aapke Jeene Ka Andaz...!” and hard-hitting content comprising of sting operations and campaign of social issues, the compact daily, DB Star was launched in 2008. Apart from Bhopal and Indore, it is also published from Gwalior, Raipur, Jodhpur, Ranchi, Dhanbad, Jamshedpur and Aurangabad.

Under the able guidance of RD Bhatnagar, Bhaskar’s chief technical officer (CTO), the newspaper is printed in 14 states and has 61 editions. The group recently launched the three new editions in Bihar. After the first launch in Patna, in January 2014, the three editions in Bhagalpur, Muzaffarpur and Gaya were strategised to further boost its foothold in the Bihar market.

With the second highest urban population to Patna and a literacy level of 81%, Bhagalpur seems to be a promising city for DB, providing a deeper reach to advertisers and readers.

The DB workflow

The printing plant at Bhopal houses two CTP machines from Krause, producing a good number of 150 high-grade PS offset plates from TechNova, per hour. The in-house pre-press division of Bhaskar has evolved from laser print and image setter to CTP, reducing the time consumption from 28-minutes to 8-minutes. A straight saving of 20-minutes plus improved quality as a bonus point for DB.

The first Krause was installed in 2007.

The DB group holds a centralised scanning department, called the Central Imaging Centre (CIC) where all the pictures sourced from web, agencies, photographers or press notes are processed by a team of experts. Based on the machine calibration of individual press and the newsprint mix, algorithms are built to apply to the pictures that are finally selected for publication.

Earlier, DB had around 58 scanning locations across India. Now with just seven CICs, they deliver consistent picture quality throughout the Group. These CICs have been established at Jaipur for Rajasthan, Chandigarh for Chandigarh, Punjab and Haryana, Aurangabad for Maharashtra, Indore for Madhya Pradesh and Chhattisgarh, Patna for Bihar, Ranchi for Jharkhand and Ahmedabad for Gujarat.

DB also uses a combination of ICONS profile and customised application for colour management on all the presses. A GMG colour server for print enhancement will be commissioned soon.

They have also developed an algorithm based on various parameters like the picture quality using Histograms, Exif (Exchangeable Image File Format) data of camera, and software for reading machine calibration data, which has been developed in PHP using its image magic code. The software also takes the input of image editors based on their visual evaluation of the picture and then applies the algorithm on the picture. Almost 90% of the pictures are corrected in no time.

A surprise for many, the Manugraph press at Bhopal do not employ any automated registration or inspection system. They rely more on humans than technology and have been doing it successfully for the past 50 years.

The money game

Profit = selling price – cost price. The old school rule is not applicable to the newspaper industry. The cost of one newspaper at Bhaskar, including newsprint, ink, electricity, labour, transportation comes to Rs 7-8. The same newspaper is sold at Rs 3-5. So, how does the newspaper industry survive? Advertisement is the answer. Ads are the major revenue generators for any newspaper.

Paper and Ink

Dainik Bhaskar procures newsprint from Indian manufacturers like Rama, Khanna and many others. It also imports paper from Russia, Canada and Korea. Depending upon the cost of an ad and news content, one newspaper is structured into different quality papers as a way to optimise cost.

Newsprint is the most expensive component (about 60% of total production cost) of newspaper printing. There is a special monitoring team responsible for newsprint waste reduction at all 59 print locations of Dainik Bhaskar.

Huber group (earlier Micro Inks), DIP, Flint are some of the key ink suppliers. The company employs centralised purchasing of all raw materials. After newsprint, ink has the biggest share in the production operational expenditure.

To ensure its optimum consumption, a dedicated team functions at DB, to ascertain that every gram of ink in the bucket is used for printing. Ink mileages are regularly monitored and ink saving application is also installed to help reduce consumption without compromising on print quality.

Sustainability

Various steps have been taken by the group to ensure that its systems are green and 5S-enabled (Japanese workspace efficiency method: Seiri, Seiton, Seiso, Seiketsu, and Shitsuke).

The company has migrated to green technology using viogreen chem-free violet plates at its plant, which saves water and generate fewer disposals. Installing ETP/STP at its major print facilities is a good initiative taken by the group.

The Bhopal press has replaced all lights with LED for power optimisation, which has resulted in 30% energy saving. The company has installed ambiators for its KBA presses in place of air-conditioning resulting in 50% energy saving. The plant ensures 100% usage of recycled newsprint. Plus it has installed rainwater harvesting and running competitions as part of its go-green initiatives.

The best foot forward

Dainik Bhaskar works towards its chairman’s vision, “To be the largest and most admired language media brand enabling socio-economic change.”

Apart from the innovations like gold printing, gate fold, half fold, 3D effect, French window, butterfly style, and fragrant paper, the news group drives several CSR initiatives. It has initiated a very interesting concept – the ‘No Negative Monday’ concept. Under this concept, only positive news is highlighted on the front page of all the 61 editions every Monday.

All this has reaped dividends for India’s largest print media firm. Total revenues have shown a growth of 9.2% YOY to Rs. 4838 million in Q2 against Rs 4430 million of Q2 of last fiscal.

|

The DB trivia |

|

1. Dainik Bhaskar was launched as Subah Savere in 1956 and later renamed in 1958

2. Ramesh Chandra Agarwal, chairman, received Rajiv Gandhi Award in 2009 for lifetime achievement in the field of journalism

3. Subject of choice for case study in India’s top B-schools like IIM-A, IIM-B, Mudra Institute of Communication

4. Has printing unit in Noida (MP Printers) for commercial printing

5. Voted the Most Trusted Brand for 2015 (in the Hindi newspaper category) by the Brand Trust Report, India

6. Dainik Bhaskar won more than 15 national and international awards

|

The first Krause was installed in 2007. The DB group holds a centralised scanning department, called the Central Imaging Centre (CIC) where all the pictures sourced from web, agencies, photographers or press notes are processed by a team of experts. Based on the machine calibration of individual press and the newsprint mix, algorithms are built to apply to the pictures that are finally selected for publication.

The first Krause was installed in 2007. The DB group holds a centralised scanning department, called the Central Imaging Centre (CIC) where all the pictures sourced from web, agencies, photographers or press notes are processed by a team of experts. Based on the machine calibration of individual press and the newsprint mix, algorithms are built to apply to the pictures that are finally selected for publication.

See All

See All