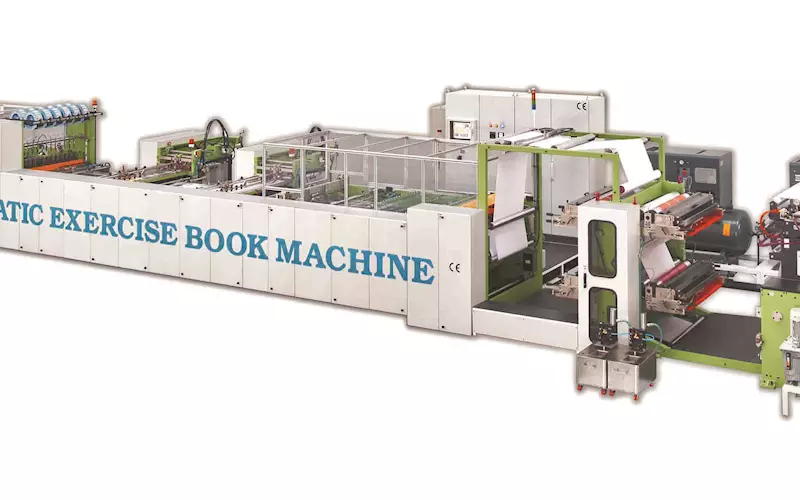

Enhanced automation and inline operations enables Line O Matic’s Nova RB104 to convert paper reel into a finished notebook at the rate of two lakh books per day, finds out Rushikesh Aravkar

Nova RB104, which is a flagship product of Ahmedabad-based Line O Matic Graphic Industries, was launched at PrintPack India 2011 and since then the machine has seen more than 75 installations across the globe.

"Nothing else on the market will give you such a price performance ratio with minimum manpower requirement," explains, manager - marketing, Mukesh Sonani. He further adds, "The quality it produces for its size and price is amazing."

The fully automatic notebook exercise book machine is bundled in such a way as to bring together all the operations required to produce a notebook from paper reel in an ergonomic manner, which takes the process of notebook making to a new level. Sonani, says, “The machine is build in such that the operators’ life is made easy. Only two operators with three assistants can handle the entire machine flawlessly.”

To put it in parts, the kit comprises of reel unwinding stand, flexographic printing tower, cross cutting unit, sheet overlapping unit, sheet counting and collating unit, one inserter for pre-printed index covers, one inserter for pre-printed title covers, wire stitching unit, folding unit, square back pressing unit, book front cutting unit, book separating cutting unit, book delivery table, waste removal system, and a centralised control panel (PLC) which takes care of all the units.

Technical Features

Line O Matic’s Nova RB series comprises of two models based on the width it can handle. The Nova RB120, which can handle a 1,200mm wide paper web, is the counterpart of 1,040mm-wide Nova RB104. The Nova RB104 is equipped with automatic inking system and automatic cover pilling station which was missing in its RB120.

Equipped with Erhardt + Leimer’s web guiding system and hydro pneumatic tension control system, the Nova RB104 has an excellent control over web alignment. “The shaftless unwind reel stand means tension control is better so there are fewer web breaks. The design is also said to make the press easier to operate and allows "top-level" automation features to be incorporated.

The two flexo units on each side of the web enables two-colour printing on both sides of the web. The machine is also available with option of three printing units on each side. These units can use flexo photopolymer plates or laser engraved rubber sleeves as per the requirement of the user. Also, the automatic inking system adds to the simplicity of the process. The machine can handle paper stock from 45 to 75gsm for inner pages while the inserter for pre-printed covers handles 50-350gsm covers.

Sonani says, “The machine runs at 250 m/min speed, converting up to 14 metric tonnes of paper per 24 hours depending upon gsm of paper, diameter of paper reel and reel width being used. This calculates to two lakh A5 size notebooks up to 96 pages per day.”

Equipped with nine stitching heads from Hohner or Deluxe, the machine can affix three wire stitches per book. To improve stitching efficiency, the machine can be supplied with 12 stitching heads as a part of optional package.

“The components like automatic ink circulation system, waste removal system, stack delivery table etc. come as a standard with the machine. Optional features such as flipping or turn bar unit, air compressors, shrink wrapping system can be incorporated in future,” adds Sonani.

Internet connection and SMS notification

The Nova RB104 has embedded internet wi-fi in control panel. This enables the user to operate and control the machine using his laptop via internet connection. Sonani says, “Parameters like speed of the machine, compressed and dry air pressure, paper reel diameter, cover feeders, supervisor or operator controls for motors and drives, production output etc can be controlled remotely, thanks to this feature.”

In addition, the machine is supplied with inbuilt SMS notification system which, sends SMS to maximum four mobile numbers fed into the system on daily basis. The SMS comprises of production data like number of books produced, production in tonnage, number of paper reels, number of sheets, speed and hours of operation etc.

Service support

Besides the quality of the machines, company emphasises on prompt after-sales service as well as total customer satisfaction, is the key to the company’s success in India and overseas. “A dedicated team of expert technicians takes care of proper installations, training and maintenance regularly backed up by prompt service and spare parts divisions,” adds Sonani.

Line O Matic has a state of the art manufacturing facility with indigenous design and capability for making its world class and internationally accepted machines. The new offerings will take company to provide the exercise note book industry with the right machinery to meet the growing demand with high quality products and best performance.

Line O Matic boasts of a manufacturing facility with indigenous design and capability for making its world class and internationally accepted machines. According to Sonani, the new offerings will provide the exercise notebook industry with the right machinery to meet the growing demand with high quality products and best performance.

See All

See All