The vexed case of anti-dumping duty

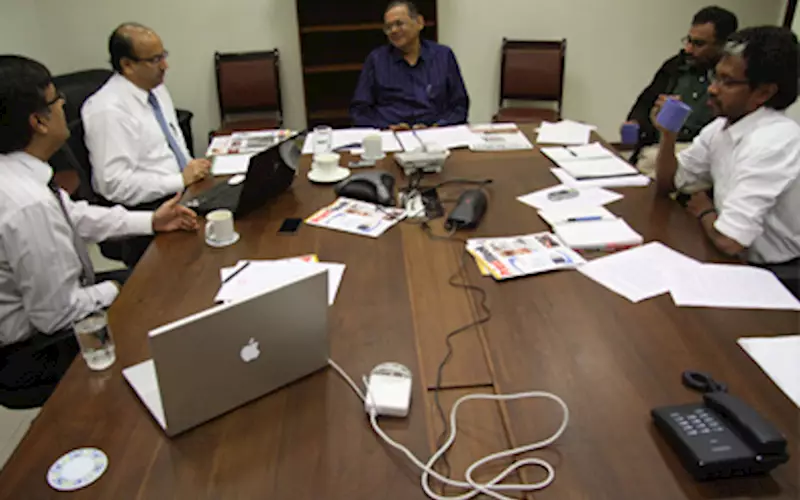

PrintWeek India hosted a discussion between the representative of the All India Federation of Master Printers and TechNova to understand the relative merits of a fair market competition in the digital printing plate arena and the large chunk of printers in need of high quality but reasonably priced plates.

07 Sep 2011 | By Rahul Kumar

| At the discussion |

| Print CEOs: Anand Limaye, honorary secretary of Mumbai Mudrak Sangh, Ravi Joshi, honorary secretary of the All India Federation of Master Printers. |

| TechNova: Pranav Parikh, CMD of TechNova; CG Ramakrishnan, chief operating officer of TechNova; and Deepak Chawla, general manager, marketing and CRM, TechNova |

| PrintWeek India: Ramu Ramanathan and Noel D'cunha |

CG Ramakrishnan (CGR): At the outset I would like to emphasise that we are not against fair and free competition.

Anand Limaye (AL): What is anti dumping? Can you explain about the lower prices of Chinese plates despite equal price of metal, cost of manufacturing, other financial burdens, involved labour charges and logistic cost plus the commission and transportation charges? And despite all these odds, how are the Chinese manufacturers flourishing while the Indian manufacturers seem to struggle?

CGR: There are two issues: One, efficiency and productivity of the manufacturing process and costs . We compare well against the Chinese here. Second is the issue of benefits and subsidies.

AL: So it’s not against fair competition?

CGR: That’s the second issue. We’re raising the issue of unfair competition arising out of the huge subsidies that the Chinese government provides to a variety of industries including printing plates in our case. Let me explain how, starting with metal costs. It is a misconception that metal costs for the Chinese manufacturers are the same as in India, or for that matter, in any other country. The Chinese Govt, through Shanghai Futures Exchange (their version of London Metal Exchange) ensures that the local producers of plates and other finished products get aluminium ingots & coils at prices that are 15% to 18% lower than anywhere else in the world (March-May2011 prices). Rest of the world uses the London Metal Exchange prices as the basis for pricing of aluminium products.

Pranav Parikh (PNP): If you compare the March-April-May’11 prices of aluminium on Shanghai & London Metal Exchange , net of VAT, there was a 18% cost disadvantage to the rest of the world, including us in India, as compared with China.

AL: So you are suggesting that TechNova is out-priced by 18% before the aluminium coils come to you?

PNP: The discounted Shanghai Future Exchange prices are available only to Chinese manufacturers of finished products, including plates, and not to us. If we were to order Chinese aluminium, we would not get this price. We will compulsory have to buy it at the London Metal Exchange prices. So this pricing benefit is given only to those who locally manufacture finished products for exports, including multinationals such as Agfa, Fuji and Kodak for use in their Chinese plants.

AL: Can’t TechNova import Chinese aluminium coils?

PNP: If we were to import Chinese aluminium, not only would we have to buy it at London Metal Exchange prices, we would also have to pay the Safeguard Duty, i.e. fast-track Anti-dumping Duty, that is imposed by our government on import of aluminium rolled products from China. This would further increase our costs as compared to the Chinese (as there is no Safeguard or Anti-dumping Duty on the digital plates being imported from China).

AL: Hasn’t the Aluminium Association of India applied for anti-dumping protection?

PNP: To offset the government supported cost advantage of the Chinese rolled product manufacturers, and protect the Indian aluminium manufacturing industry which caters to construction, automobile, electrical, food packaging & various industries, the Aluminium Association of India applied for anti-dumping protection. The government levied safeguard duty@ 14%, in addition to the normal duties on a variety of products covered under chapter 76. So if we were to buy Chinese aluminium coils for manufacturing our plates, not only do we have a cost disadvantage of 18%, due to the difference in the Shenghai & London Metal Exchanges, but we would have had to pay an extra 14% in duties.

AL: Why was the Safeguard Duty not levied on digital printing plates at that time?

PNP: All finished products, including plates that are made from aluminium coils, were entitled to be included. However, at that time, there was hardly any import or dumping of digital plates from China. Significant dumping took place in 2010-11, which compelled us to file our Anti-dumping Petition.

AL: But can aluminium subsidy and safeguard duty have such an impact?

CGR: In addition to these two factors, there are a number of financial benefits provided by the Chinese government to local producers for exports. The US government has compiled a 150 page document a year ago describing various methods used by the Chinese government to provide financial benefits to a variety of industries that are considered strategic by the Chinese government. The big issue is that China is using a variety of subsidies cloaked in various disguises to launch what one can call economic terrorism against countries that they consider as rivals in the economic sphere. They know that in the US and Europe, economic growth won’t be a key driver for the next 20 years. They have identified India as a threat and they are targeting these measures in key industries against India, such as aluminium, construction, chemicals, pharmaceuticals, leather, toys, etc. Offset printing plates, is the latest victim. Not only government-owned and independent Chinese plate manufacturers, but also multinationals having plants in China, are dumping plates in India using these benefits.

AL: You spoke of disguised subsidies for Chinese manufacturers, what does that mean?

CGR: These disguised subsidies, as per the US report, include: cash export subsidy of 13% on all plates exported; under-valuation of the currency by a minimum of 30% according to US Treasury Secretary; nominal interest rates, ranging from 0.5% to 5% (against our 14%; now 16%); loan write-offs (-the NPA or non-recoverable loans of the Chinese Banks amount to 25%-35% of their total loans); discounted power tariff; flexible accounting practices not conforming to international accounting guidelines; etc. Countries, such as China, in which the pricing and market mechanisms are influenced by government interventions in various forms instead of free market or economy principles, are classified as "non-market economies". Anti-dumping Duty cases against non-market economies are governed by a fast-track mechanism

AL: How would under-valuation of the currency by the Chinese affect you?

PNP: Currency valuation is not as relevant for domestic consumption, but has a huge impact on the international trade. An undervalued currency enables the exporters to under-price their products in terms of US Dollars. Because they end up getting approx 30% more Yuans per dollar (Yuan 6.5 to 1 USD at current rate) as compared with what they would have got if the Yuan was correctly valued (Yuan at around 5 to 1 USD ).

AL: So what you’re suggesting is: this is how the Chinese government has enabled their industries to target industries in other countries through predatory pricing. Once the domestic industries cease to exist, the Chinese exporters increase their prices and the government withdraws the subsidies. .

PNP: Yes. And another interesting aspect is that even if the exporters continue to make losses on exports, they do not have to worry about going bankrupt due to absence of bankruptcy laws. As is well known, a majority of the 80 in dependent small plate manufacturers in China are technically bankrupt.

AL: But that could also be because the MNCs have set up manufacturing plants in large numbers?

PNP: All three MNCs, Agfa, Fuji and Kodak, set up plants in China to derive the benefits provided by the Chinese government. In addition to serving the domestic market, Fuji and Kodak are using China as the base for exporting to India at predatory prices.

AL: The Indian government also provides tax and other benefits for setting up plants in backward areas. How is that different from the Chinese subsidies?

PNP: Backward zone subsidies are made available to neutralise the extra cost of doing business in those backward areas. Infrastructure is poor, skilled labour is not available, logistics costs are higher; power supply is uncertain, professionals are unwilling to work there unless incentivised, and so on. China also provides these location-specific incentives, in addition to export incentives. Export incentives described earlier are available to all exporting companies even if they are located in highly-sophisticated industrial parks. These incentives are not available for products sold locally in China; hence, the domestic prices of their products are typically higher than their export prices for India. Also, as you know, in India, as soon as the zone becomes developed, the incentives are withdrawn. For example, TechNova received no incentives when we set up a plant there in 1983. Therefore, the Chinese export incentives cannot be compared with India’s subsidies.

AL: What compelled you to go for anti-dumping petition?

CGR: During 2010-11, heavily under-priced imports of digital plates made in China intensified. TechNova incurred heavily losses in spite of all our efforts to cut costs, and the business became unviable. We had no option but to make the Petition in May this year.

AL: How do we know that the Chinese plate imports are affecting you?

CGR: We had suggested to the AIFMP that they can appoint any of the big four auditing firms to verify our financial statements submitted along with our petition. Also, we have to prove to the government that we’ve been caused injury. The government will verify our claims by sending a dedicated team of experts to our plant. Similarly, they will send their team to the Chinese exporters’ plants, if they choose to co-operate. The fact that the government has initiated action on our petition is an indication that they are prima facie convinced that injury has been caused to TechNova due to Chinese dumping.

AL: Ravi Joshi, I would like to appraise you on safeguard duty. Eight years ago Indian paper manufacturers also applied for this where the federation of print association opposed and we won in that case. So now, the federation is opposing this also. How would you confront this?

Ravi Joshi (RJ): There is a procedure which we follow, which I can’t share right now. We need to understand that as the AIFMP, we represent associations of printers in India, which in turn have printers as members. So when a printer suffers because of prices, we oppose it. That’s because it comes as a disadvantage to the printers and it hampers his business. Right now there’s a feeling among common printers that there’s a wide difference in operators supplying plates. How can we tell printers to buy Indian manufactured plates even if they are expensive material?

AL: You’re suggesting Indian printers will only consider the price and not the quality …

RJ: These days Indian printers are educated and are aware of their interest. Nobody can sell them bad quality plates even at the cheaper price. They will definitely think of the quality while buying it. If the quality is indeed poor, no one will buy it. The point is that at the moment, printers are getting very good quality plates at a very cheap price. So I don’t think quality is problem that time.

AL: It is true that Indian printing industry is getting a Chinese manufactured plate for a low price?

RJ: Printers are not worried where they are getting the plates from, the fact is that I’m getting good quality plates at a very low price.

AL: The safeguard duties were opposed eight years ago. At that time Sinar Mas entered the market. All paper mills were selling coated paper at Rs 50 per kg. Sinar Mas started at 42 per kg. Ultimately what happened all major Indian paper manufacturers had to close down. Now Sinar Mas is selling coated paper at their desired rate. My point here is that if printing industry doesn’t support the Indian manufacturer they will either have to surrender or merge with a larger company. In such scenario, do you still think that the plates supplied from China or anywhere else, will stay as low as it is today?

PNP: Ravi-ji, can I ask you a couple of questions, if you don’t mind? One: If you are convinced that TechNova will have to exit the plate business if they lose the case, would you still oppose our Petition? Two: If you are convinced that the average international price of digital plates is $8-$9 per sq/metre (as reported in a globally recognised Industry Survey Report published in 2011), would you not fear that after TechNova’s exit, the prices of imported plate in India will shoot up to that level?

RJ: There are two other scenarios I can see, for you shutting down. One, you may close down because of normal competition and second, you may have to close down due to strike or for any other reason, regardless of the anti-dumping issue. What are we supposed to do then?

PNP: Fortunately, in the 40 years since TechNova’s inception in 1971, we’ve not had to close down even once. However, one cannot say that this will never happen. And for that reason, we have multiple lines and locations, huge inventory in our central and regional warehouses, and other contingency plans. Significantly, the fact remains that if the printers feel safer importing from China instead of buying from an Indian supplier due to this reason, they can do so. Anti-dumping Duty does not prevent imports; it merely eliminates dumping.

AL: In the TechNova factsheet, you’ve silently mentioned that in case TechNova does not win you would have to close down or have a plan for something similar. What I would like to know is, are you really dependent only on the digital plate business? What about your polyester plate business?

CGR: Everybody knows that the trend is towards digital plates. Polyester plate plant is completely independent of the digital plate plant. We have made a huge investment to set up a world-class digital plate production plant and obtained the technology at very high costs. It is unrealistic to imagine, therefore, that TechNova, or any other plate manufacturer in the world, can survive without digital plate offering.

RJ: TechNova did takeover Lastra Niraj, didn’t it?

PNP: Both Stovec and Lastra Niraj were not able to survive due to the dumping of PS plates that was rampant from 2005-06. Stovec closed their PS plate operations and TechNova took over the plate unit few months later and upgraded the plant and made that capacity available to the Indian printing industry. In case of Lastra Niraj, Lastra exited and the local partner wanted to also exit and TechNova stepped in to ensure similarly that the capacity was available to the Indian printers

RJ: That’s what I am saying. Why should we be worried about these digital plates so much, when polyester plates are available?

PNP: Ravi-ji, you know that polyester plates are meant for small offset, short-run, moderate quality jobs. For large format, high quality, medium to long-run jobs, one requires aluminium plates. And for extremely high-quality jobs, one needs CTP or digital plates. That’s why, the industry has aggressively adopted digital plates.

AL: Yesterday we received a letter from a vice president and a past president of BMPA, Fred Poonawala asking why this attitude should not be termed as a short term vision? I don't think that the printers are thinking of this issue -- it’s short term or long term. I think right now high on his agenda is his work. I would like to putforth that there are a number of commercial printers where the consumption is very high. For them, won’t the input cost be very high?

PNP: I would like to add to what Mr Limaye has said. If TechNova shuts down, then the prices of imported plates will shoot up to match the international prices.

RJ: Are printers only dependent on digital plates? No. They are not dependent only on digital plates. They have other options. The consumption of digital plates is definitely increasing but what I’m saying is, that I can’t sell the commodity to my client for a cheaper price, so I’m not only depending on digital plates.

PNP: We believe that within the next five years, printers will not be using PS plates. All the major plate manufacturers have already exited the PS plate business or have plans to do so. Even in China, the number of PS plate manufacturer has reduced dramatically;

CGR: Even if we accept your hypothesis that commercial printers can switch to PS plates from digital plates, what about newspapers, export book printers, packaging printers, small offset printers (who need polyester CTP plates)? They would lose their competitiveness and effectiveness if they had to switch to PS plates. The ones to suffer most will be the 25,000 small offset printers who are totally dependent on polyester plates, made exclusively by TechNova.

RJ: In this context you had mentioned that TechNova’s overall existence is dependent on digital plates and plate business because the digital plate business is a substantial percentage of total TechNova’s total capital employed loans and people.

PNP: Yes, if TechNova’s digital plate business becomes unviable, it will impact TechNova’s other businesses as well. We’re not putting a hypothetical question as during the years 2008-09, we had a real reason to close down. I must tell you that the last three years of the 40 years that we have been in existence, have been the most strenuous. When we were small, we had a smaller investment but in the last 40 years TechNova has ploughed it all back. Since 1971, when we opened in Mahalaxmi compared to 1981 when we moved to Taloja for the first PS plate plant and then the first digital plate plant in 2003, at every stage of TechNova’s life cycle, we have invested everything we earned back into the print industry.

AL: I would like to put a question to TechNova and the federation. In your factsheet you have mentioned that you had detailed discussions with AIFMP office bearer twice in December 2010 and June 2011. What I would like to know from both is: like your agreement on PS plates, why couldn’t you enter into a similar agreement for digital plates?

PNP: I think it’s a fair question. We did make an offer both in December’10 and June’11 that we are willing to arrive at a fair formula for regulating the digital plate prices just like we did for PS plates, provided AIFMP actively supports our petition for Anti-dumping Duty. Though the office-bearers of the AIFMP were completely satisfied that the PS MOU was implemented fully in letter and spirit, concerning digital plates, they did not respond favourably to our offer and decided to oppose our Petition.

RJ: Unfortunately for whatever reasons, the proposal from TechNova was not found to be acceptable to the AIFMP. This is what I recall of both the discussions. We did analyse TechNova’s proposal. Being a federation we are not the people who can take a decision. The General Council, which is the decision making body, did not accept the proposal. It took into account the printer, who is more worried about his own survival. It’s as much like TechNova having their own reasons to be in the race or not. In the same way, the printers have the same concerns – to be in or to be out. Any printer will address their own problems. As a community of printers, they are worried about their own existence of buying plates at a very high price, they are not willing to. So naturally they thought that we should not support anti-dumping application. If tomorrow TechNova closes down, they won’t have supply.

AL: If at all now, for instance, the Federation loses the case whether will this bitterness bring manufacturers and printers together?

RJ: There will definitely be bitterness. To solve it amicably, we have convened a meeting in September, where we will be discussing the issue. As office bearers it’s our job to request our members to re-consider their issues but at the same time we also have to give a fair chance to competitors. So it all depends on how people will get convinced and we cannot compel them to come to a forced conclusion. We all think TechNova is a great company, but if they have to close down, they have to. What can the printers do?

Additional Questions.

(These are the points raised by Ravi Kapoor of RKL Printers, a GC member nominated by MPLA against Fred Poonawala’s comments on anti-dumping petition)

Ravi Kapoor (RKP): I fully agree anti dumping duty is to protect local industry, if the said goods are dumped in the exporting country(in our case India) and it should be stopped.

CGR: Our appeal is that the said goods are dumped and hence we need level playing field. RK Printers is saying that if there is dumping it should be stopped. We are backing up our appeal with facts and figures being substantiated on dumping from China. If our data is correct and accepted by government, it will be proven and there for all to see and accept it. The facts will speak for themselves.

RKP: As you may be aware the local paper manufacturer in India filed the petition in DGAD to impose anti dumping duty on paper and after thorough investigation it was rejected and if Chinese printer can offer its product 30% cheaper he would export from China itself and he does not require to set up shop in India and he can compete from China itself.

CGR: As mentioned earlier, the data that we have submitted will be verified by the Directorate General of anti-dumping . They will after due and detailed verification of domestic industry and the Chinese exporters data arrive at conclusion of dumping, injury to domestic industry and the causal link that injury is caused due to the dumping. The issue is that the Chinese plate manufacturers are able to dump at such low prices because of the huge benefits being given by the Chinese government which has been detailed in answer to question two of our FACT note. Hence as per WTO rules and guidelines, if they export to India at dumped lower prices using these NON MARKET ECONOMY benefits , it will clearly prove dumping. Similarly if Chinese printers use the same benefits and price their products 30% cheaper and export to India without setting up base in India, thereby impacting and injuring Indian printers the Indian printers can appeal to government of India against this dumping and get level playing field in form of anti dumping duty. Incidentally, China has been treated is considered as a non-market economy by India and many other countries.

RKP: I fully agree if the goods are dumped in exporting country (India) or if the goods are sold much below the cost that is sold in domestic market the anti dumping duty is to be levied but this is not the case in printing plates since the plates sold in India are at the prices sold in home country and at international prices world-wide for eg Hong-Kong, Singapore, Dubai etc.

CGR: Prices situation mentioned above by RK Printers are not correct. Prices of digital printing plates sold by the same MNCs in other countries exported from China are 25-35% higher than what they are exporting to India. Ex factory prices of the MNCs selling Digital plates in China are higher than the CIF prices to India. Prices of Digital plates in India are one of the lowest in the world. Prices in many countries vary from a range of 20% to 60% higher than in India.

RKP: I fully agree with you, if imports from China and Japan are not restricted but if the anti dumping is levied the imports would become expensive as such the imported plates sold in India are at least 10%-12% higher than the local manufacturer and also the domestic manufacturer does not pay the additional cost like loading, customs duty, special additional duty, freight etc which gives the clear price advantage of over 15%. Like any prudent local manufacturer has to only price his product just 2 to 3% less than the above landing cost to control the market and have absolute monopoly. The Indian printer is therefore made to pay more for the goods if the anti dumping duty is levied or otherwise the advantage shifts to the local manufacturer at the cost of the local printers who thereby lose the advantage of being competitive in the international market.

CGR: Prices of imported plates being 10-12% higher than domestic manufacturer as mentioned is not correct at all. The imported plates are undercutting and underselling the domestic manufacturers’ price by leveraging the benefits given in China. That is why the local manufacturer is affected and injured.

RKP: Yes the MoU was signed and adhered at certain times which we are all aware, if the prices were charged as per the MoU then how come when the prices of scrap aluminium dropped to 85.00p/kg from 115.00p/kg prices of the TechNova plates remained the same most of the time. in fact I believe that the PS plates in the international market was around 2.8 USD/sq/mtr and after adding other costs like customs duty, special additional duty, etc., it comes to around 3.8usd/sq.mtr, now the local manufacturer has only to price his products just below the landed cost of the imported plates to have unfair price advantage and enrich himself, can we printers be a silent spectators to this.

TechNova comment

It is totally untrue that Technova plate prices were the same when the LME had dropped and the prices of scrap Aluminium had reduced from 115/kg to 85/kg. We have reduced prices in line with what we have agreed in the MOU. Out of the 14 quarters since we signed the MOU, we have reduced prices three times , increased six times and effected no change five times. The AIFMP audit committee has clearly stated that TechNova is implementing the MOU in letter and spirit. On the other hand TechNova has not implemented the full price increase as per the MOU formula and has a substantial under recovery of more than Rs 25 sq/mts as of date. This has been done keeping in mind the overall cost impact to customers, the requests from AIFMP and the market situation.

| Anti dumping - at a glance |

|

CG Ramakrishnan

Anand Limaye

Ramu Ramanathan

See All

See All