RotoMetrics launches multiple products

Die manufacturer RotoMetrics launched an array of products, such as Pin Eject, RD 300 and BladeShield Blue at Labelexpo Brussels 2015.

01 Oct 2015 | By Rahul Kumar

RotoMetrics’ most recent innovation for die-cutting precision parts is the Pin Eject option on solid dies. The solution is a proprietary method of eliminating build-up of small particles of die-cut waste that can result in broken cavity blades. The Pin Eject solution was designed for challenging cavity sizes as small as .0625" (1.6 mm). Applications include disposable medical products, automotive gaskets, pharmaceutical applications, laser sheets, waste-free boarding passes and tea bags.

“We thank our loyal customers for supporting us over the past 50 years and into a strong future. We take our customer relationships very seriously. We listen carefully and learn how we can support our customers’ profitable growth. Customers have taught us to be fast, reliable and innovative.” Bob Spiller, president and CEO, RotoMetrics, said.

To accomplish this, Spiller said the company offers same day or next day delivery on its core products. “RotoMetrics’ on-time reliability for flexible dies in Europe has been greater than 98% on time for 2015,” he claimed.

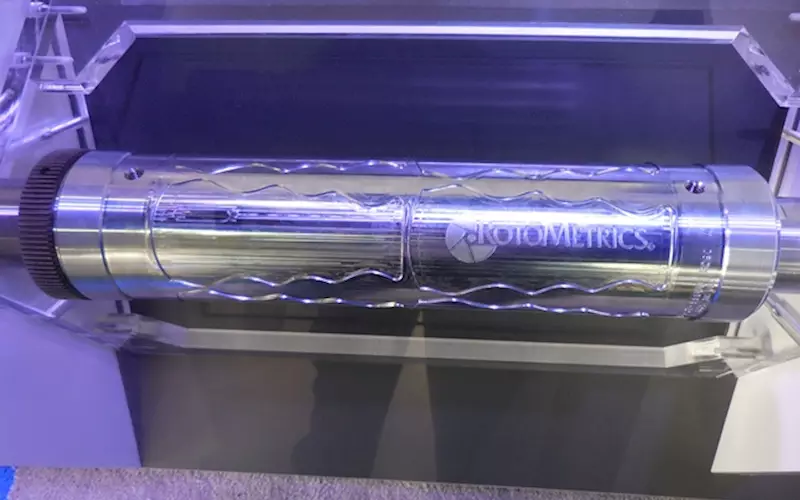

Among other new products, the RD300 is a solid die designed for high quality, custom converting applications. Whether you’re cutting engineered precision parts, thick substrates, thin films, nonwovens or synthetic constructions to convert medical components, the RD300 is up to the challenge. It features the superior steel, through-hardened (60 - 62 HRC), industry-leading precision machine sharpening, tight tolerance on cut depth and part size, multi-level cutting, optional material management solutions, among others. Applications include tag and label converting, disposable medical scrim materials, in-mold labels, velcro and nonwoven products, dust sensitive applications, unsupported films, among others.

BladeShield Blue, on the other hand, is a new coating to help avoid adhesive build-up on cutting blades. As a ceramic based coating, it has a wear and chemical resistance and also adhesion to the flexible die surface. It’s available for all Accu-Series flexible dies and can be combined with all available treatment options, including nickel, chrome, FlexPlus, and FlexPremier.

See All

See All