PrintPack 2017: Sodhisons to launch three new products

Coming to PrintPack India 2017 on its golden jubilee year, Sodhisons Mechanical Works will launch three products – a high-end automatic thermal lamination machine produced with European technology for metalised polyester film, with hot knife cutting system and electromagnetic heating system at speed of 100m/min and accuracy of +/- 1 mm; a carton inspection machine for products like pharmaceutical cartons and tobacco boxes; and the Rogler ERP software from Austria to cater to all print-related re

30 Jan 2017 | By Dibyajyoti Sarma

The machines will be launched in partnership with Daya. Considering the changing market scenario and varied customer demands for complete solution under one roof, recently Daya and Sodhisons came together to form a company called Shenso Graphic Solutions. Together, they will launch the high-end machines covering majority of solutions under one roof.

According to Rakesh Sodhi of Sodhisons Mechanical Works, the automatic lamination machine can handle paper from 100 to 650 gsm and PVC, BOPP, PET, Metalised PET films from 7-40 microns at the production speed of 60-80 m/min. It contains electromagnetic heating system for main nipping roller, and has four servo drives, each at feeder, overlap, tension controller and hot knife.

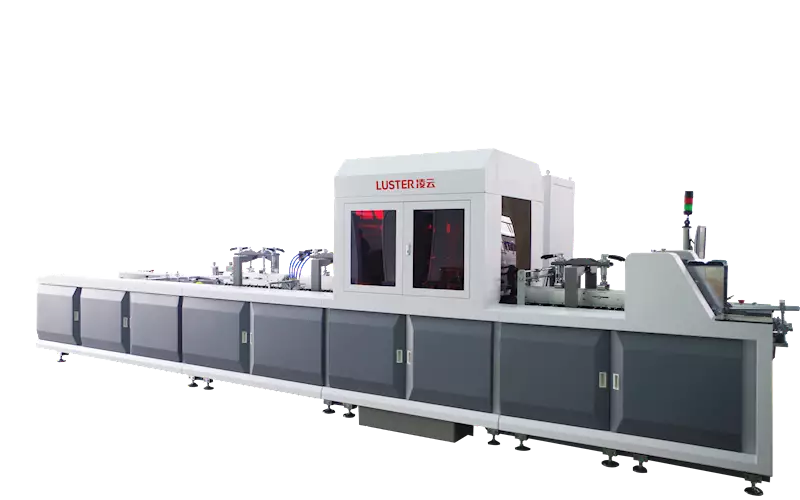

The carton inspection machine is for sheetfed printing quality inspection, such as pharmaceutical cartons and tobacco boxes. “It can inspect defects like streak, missing print, dirty spot, splash, mis-registration, colour deviation, miss stamping, improper position of stamping, concave-convex and foil stamping deficiency. The function of variable data inspection enables it to read codes, analyse code level and inspect other code defects,” Sodhi said.

He said the machine has been specially developed for inkjet printing quality inspection of small sheet packets. The machine is equipped with sheetfeeding module, surface finishing module, position adjustment module, printing module, inspection module, double elimination module, sheet collection module and so on. In the speed of 80m/min-90m/min, it can produce 20,000-30,000 packets per hour. For inspection alone, it can reach 150m/min and finish 40,000-60,000 packets per hour.

Talking about Rogler, Sodhi said it is one of these typical German/ Austrian owner-operated international innovators who help clients focus on their strength. “The product offering is highly customisable and the services are highly adaptable to local needs and customer preferences. The system covers all the steps in the value chain of modern production (not only printing) companies and all aspects of workflow and enterprise resource management,” said Sodhi.

Beside these, the company will also showcase Model RB6040 of the Zhengrun rigid box machine. The full-automatic paper box forming machine is composed of gluer (the paper-gluing unit), quad stayer (four-angle sticking unit), spotter (the positioning-sticking unit) and former (the box forming unit), which are controlled through a PLC in a linkage mode. The machine can handle paper dimension from 95×180mm to 610×850mm, and cardboard dimension up to 600×800mm.

By the end of 2016, the company has installed 20 Zhengrun fully automatic rigid box machines.

Sodhi said since PrintPack 2015, the company has enlarged its product portfolio and included many other solutions from pre-press software to finishing machines. This year, Sodhisons will be present in a 276 sq/m stall. “With all solutions, from MIS/ERP to post- press/ binding/finishing, we serve all needs of machinery for our customers,” Sodhi said.

See All

See All