Pragati prints 10mn unique cartons in the latest packaging tour de force

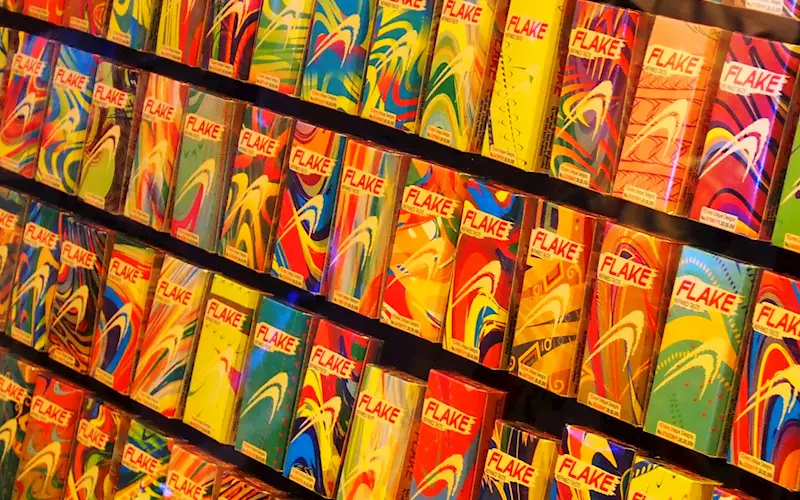

In what is said to be the world’s largest fully variable packaging design project, Hyderabad-based Pragati Pack has produced 10mn individualised cartons for one of the largest FMCG majors in the country.

29 Feb 2016 | By Rushikesh Aravkar

The 10mn cartons printed on HP Indigo press are already in the market when Pragati and HP jointly organised an open house to unveil the packaging tour de force at Hotel Taj Krishna in Hyderabad on 26 February 2016.

Team Pragati and Team HP unveil the packaging masterstroke

Speaking to an audience consisting of representatives from FMCG brands, Harsha Paruchuri of Pragati, said, “The client brief was simple. They wanted every pack to have a unique design and a unique number which identifies it, and the inner flap was to have the name of the art form that inspired the design.”

Digital approach

While conventional technology can print on a mass scale, the variable element meant that digital technology was a logical choice.

The HP Indigo WS6600, which was installed by Pragati in late 2014, and HP’s Smartstream Mosaic software were deployed for the project.

“Thanks to Mosaic’s special algorithm 10mn unique and vibrant designs were auto-generated from a set of seed designs developed specifically for the campaign,” added Paruchuri. “For the consumer, this means that no pack would repeat itself and that the consumer holds a one of a kind pack.”

Mosaic uses the vector PDF files of the seed designs as input, and generates a large number of variations by randomly transforming the file, using scaling, transposition, and rotation. The results can then be used as the variable image assets in the graphic design of VDP jobs.

According to Paruchuri, it is important to get the seed designs right. “Seed designs have to have sufficient variability, detail and non-repeating patterns for this to work.”

Operational challenges

The major challenge for Pragati in the pre-press stage was the file management of the 10 million designs and converting these to printable data. “The ripped data huge, as big as one terabyte,” said Paruchuri.

The major challenge for Pragati in the pre-press stage was the file management of the 10 million designs and converting these to printable data. “The ripped data huge, as big as one terabyte,” said Paruchuri.

On the printing and conversion front, 1.5mn metres of material was first printed on HP Indigo press with six million impressions and then flexo presses were used for overprinting of gold and varnish in a tight register. “We ensured stringent quality control mechanisms so that all packs are within tight register tolerance while overprinting as well as sheeting and die-cutting.”

Countering all the hurdles with internal expertise and help of HP team, Pragati completed the packaging job in 26 days and delivered it three days ahead of the schedule.

In terms of results, it’s still early days. Paruchuri said that this is the largest digitally printed pack design project of its kind. “We want to make the most of the Indigo press by exploiting all that it can do and not just keep it limited to churn out short-run jobs,” he added. “The technology has delivered a brilliant marketing idea. Digital print is an enabler.”

-

- 10mn unique packaging designs

- 10mn individualised cartons

- 1.5mn metres of paperboard

- 6mn digital impressions

- 26 days to accomplish the job

See All

See All