Manjushree invests in a multi-layer shrink film plant

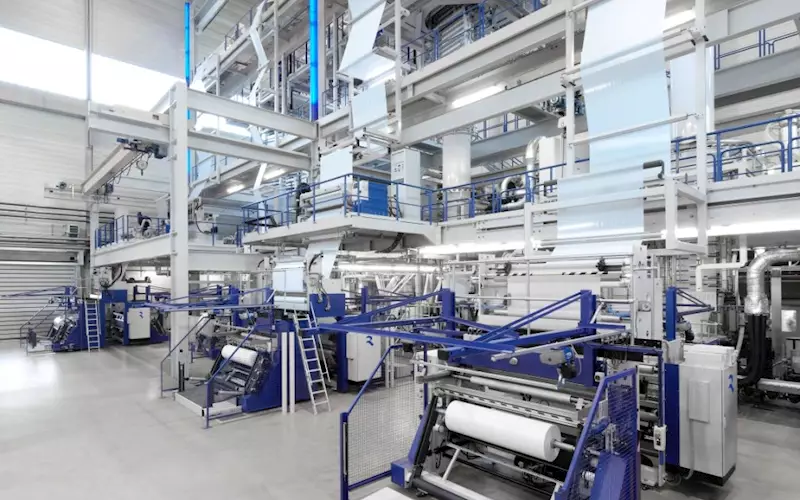

Manjushree Technopack, perhaps South Asia’s largest packaging company, inaugurated a fully automatic multi-layer shrink film packaging plant recently. The plant is has installed Reifenhauser’s third-generation Evolution blown film line with a 2600 mm width to suit multiple film application with a focus on collation shrink film.

27 Jun 2016 | By Rahul Kumar

The plant in Bidadi (near Bengaluru) has the capacity to produce 12-15 tonnes of shrink film every day. With this plant, Manjushree Technopack will be providing multi-layer shrink film packaging solutions to their existing clients who include beverage majors like Pepsi, as a tertiary packaging solution, to make bulk their packaging lighter.

Vimal Kedia, the managing director of Manjushree Technopack said, “Being one of the largest PET pre-form manufacturer for leading beverage brands like Pepsi and Coca Cola, we saw it as a natural progression to venture into shrink film packaging to achieve an unbeatable status in the packaging industry by becoming a 360 degree packaging solutions provider to our clients.”

It is in this sense, shrink film serves the same purpose of holding several product packs or bottles together and one of the primary reasons for this move is the considerable cost advantage - shrink film costs one-third that of corrugated boxes – and the aesthetic appeal of transparent packaging. A range of industries are using shrink film including beverages, packaged drinking water, food processing, cosmetic, pharmaceutical, distilleries and wine.Kedia added, “The shrink film packaging industry in India is growing exponentially, led by several beverage majors, 50% of whom have made a shift from traditional corrugated boxes to multilayer shrink film packaging according to Manjushree.”

The line is equipped with Evolution Ultra Range Extruders and Ultra Cool technology. The patented Ultra Cool is the current state of the art in high output blown film cooling systems, with an output of up to 700 kg/hr with collation shrink recipes. The line is provided with the Evolution WP winders for winding quality for multi up rolls.

The shrink-film line is equipped with the Evolution C automation system, in which, operator controls are integrated into a single 24-inch smart app touch screen panel, for operating efficiency and operator friendliness, that meet today’s market requirements.

PET is a major rigid plastic packaging format used to pack a wide range of beverages including CSD, fruit-based beverages and bottled water. Increased demand for products in bulk is further driving demand for PET bottles in the beverage industry. To create ease and convenience in sealing and transportation of PET bottles and products in bulk, shrink film packaging is growing in popularity as a secondary form of packaging, compared to the use of corrugated cartons.

See All

See All