Malhar Digicomm adds Esko’s automated cutting kit

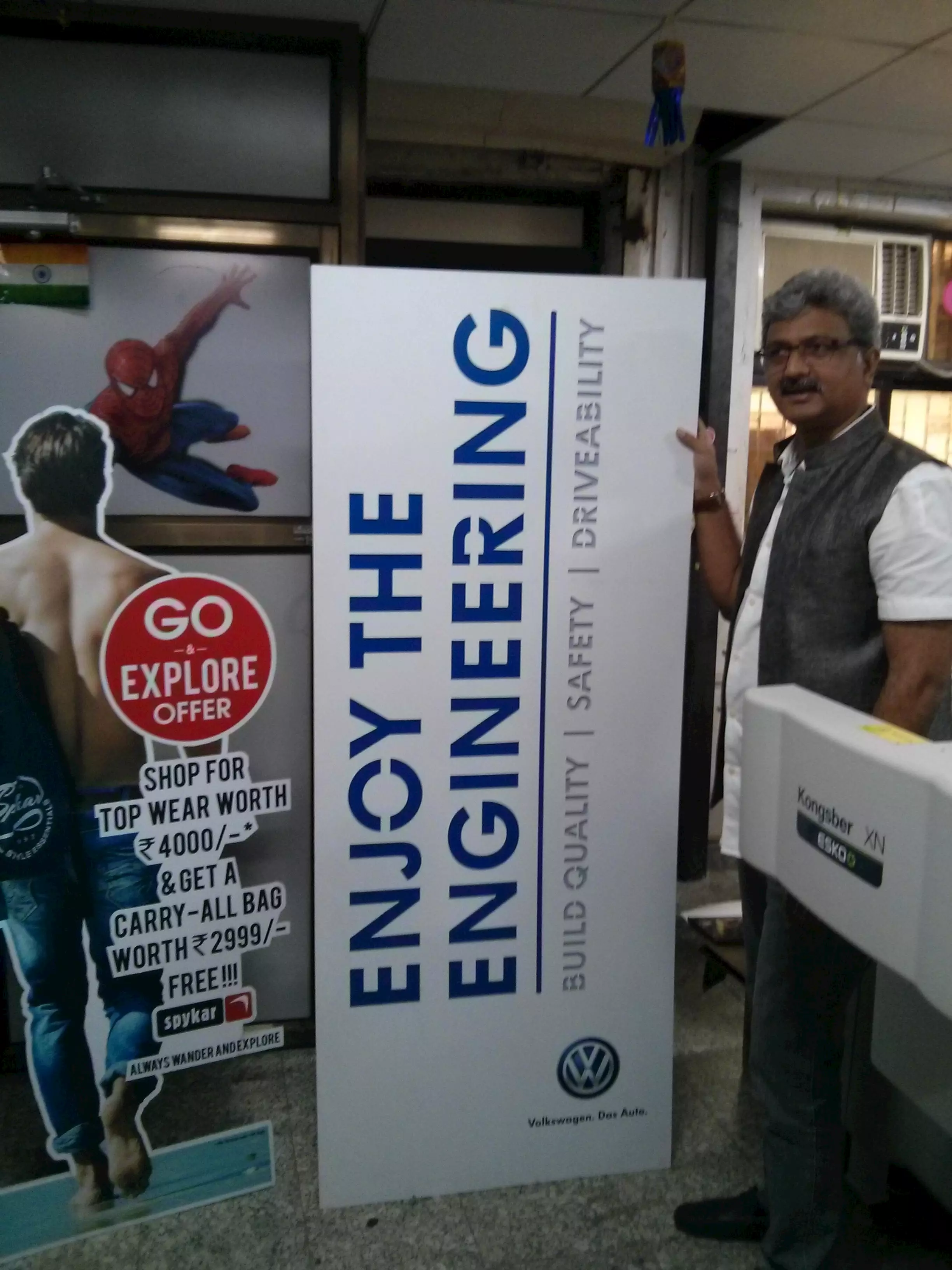

Malhar Digicomm, which runs a host of wide-format machines, has added automated cutting to its shopfloor after buying an Esko Kongsberg XN 24 cutting table.

17 Nov 2014 | By Rushikesh Aravkar

The firm, based in Andheri, Mumbai, has also invested in Esko software ArtiosCad 3D version and i-cut suite what the company calls ‘design-to-print-to-cut’ workflow in a bid to transform the manually operated facility to a fast-growing digital point-of-purchase (POP) and point-of-sale (POS) company.

The digital print company headed by Milind Deshpande designs and manufactures display products for retail outlets. This includes freestanding displays, end-aisle displays, and shelf displays. It prints on diverse materials and even does custom moulding as part of its displays.

Deshpande said, “With the Kongsberg XN digital cutting table, we are now able to cater to big brands such as Top Ramen, Being Human, Volkswagen and GM Electricals amongst others. Today, we cater to projects which are usually in the range of 1,000 to 5,000 pieces, but now we can work on much smaller or even larger quantities.”

Deshpande further said, “Since the work was complicated and took too much time when done manually, we needed a solution that could bolster our productivity and then we could grow. Moreover, prior to installing the Kongsberg, we were sending our jobs outside and the finishing part, which is important for a POP or POS, was not as per our expectations. The POP business is growing fast, but you have to offer brand owners and retail customers a good solution, or you will not be able to keep them as customers. We understood that we could not work manually anymore.”

The Kongsberg XN 24, which can handle sheets up to 1680x3200mm, is armed with comes with MultiCUT HP high power milling head with water cooling system running at 60,000rpm.

“It is easy to use and that helps us be more creative, productive and turn work around faster. We also liked the size of platform it offers,” said Deshpande.

With this configuration Malhar can address array of segments such as signage, display, POP/POS, packaging mock-ups as well as corrugation with special tools.

The new set-up is up and running live at the facility since a month ago. Esko’s stall at the recently held IndiaCorr Expo was designed and developed at Malhar using the new kit.

Malhar also runs a variety of printing and finishing kit, including a range eco-solvent, solvent and HP Latex wide-format equipment.

See All

See All