Konica Minolta’s AccurioPro offers end-to-end workflow automation

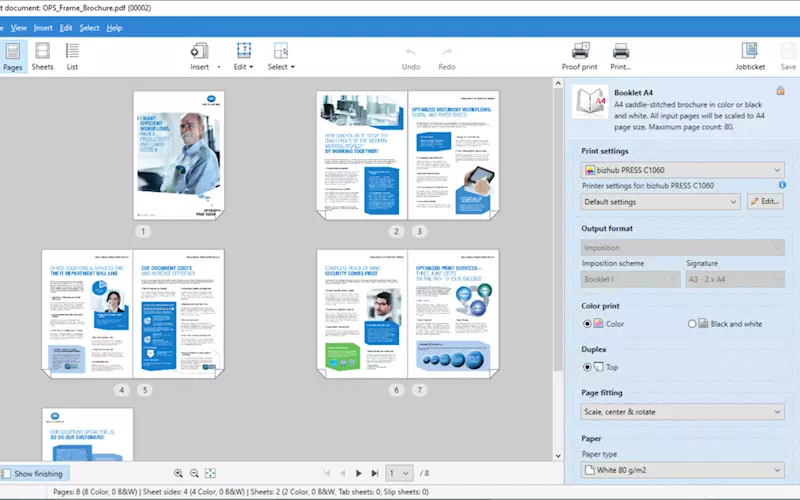

With print service providers aggressively engaged in upgrading as well as adding new services and applications to cater to the next generation demands of customers, workflow automation has become pivotal for seamless and streamlined business operations. To meet this demand, Konica Minolta has unveiled the AccurioPro software platform, offering end-to-end production automation.

20 Jan 2017 | By Dibyajyoti Sarma

The solution is specifically tailored to be modular (pay only for the components needed), flexible (integrates with other common graphic arts software), scalable (supports small-to-large operations), and comprehensive (features beyond pre-press to incorporate colour management and finishing).

According to the company, the AccurioPro can be implemented in shopfloors of different shape and size, and print firm can customise the product as per its requirement.

The software offers JDF interoperability for seamless compatibility with existing commercial workflows like Agfa Apogee, Kodak Prinergy, and Screen Equios.

The AccurioPro Conductor has been tailored for centralised and intelligent output management. Job specs (via JDF) can be leveraged from a print MIS to effectively and efficiently load balance production across a fleet of digital presses without operator intervention. The conductor can also support finishing automation with the possibility for out-of-the-box integration due to a unique JDF converter that eliminates differences between vendors that are often hurdles to integration.

AccurioPro Cloud Eye incorporated in the solution is for remote management and administration of colour quality and standards, and is particularly useful for multi-site quality control. Cloud Eye helps printing businesses in day-to-day colour control, sharing colour data across devices/sites, ICC profile creation, and reporting to ensure devices are within tolerance.

See All

See All