HP will unveil a new double-engine, double speed narrow web press, the Indigo 8000, upgrades to the Indigo 20000 and 30000 presses, a new ink and a set of HP patented post-print converting solutions, developed and qualified by HP and partners.

Visitors to Drupa will see the three presses in action, which will support HP Indigo ElectroInk Premium White, a new ink that HP claims will help converters deliver a wider range of opacity levels, up to 81% in four hits that was previously only available with silkscreen, claimed HP.

At the media event held in Israel, the new 8000 was shown running at full speed inline with an ABG FastTrack semi-rotary die-cut unit, Digicon, and an AVT inspection technology.

The 80 meters per minute or 262 feet per minute press features two WS6800 engines, an aspect that HP has employed in its HP 50000 press, which had two 20000 engines enabling doubling of speed.

Alon Bar-Shany, general manager, Indigo division at HP, said, “In the last four years, we have tried to focus on what is important for our customers. The first standard is quality, and we have made significant improvements by making fundamental changes to the Indigo process.”

Justifying the reason for ganging two engines to increase the speed of Indigo technology, an HP representative, said, “The question is: what is the best way to do it – by the process speed or increasing the number of engines? From a business aspect, increasing the number of engines was a legitimate way to hike productivity. So this time, we chose ganging of the machine. We received very good response from the customers with whom we exposed the idea.”

Explaining the Pack Ready solution, HP’s R&D chief for the solution, Asaf Salant, said there are four value proposition to the technology – zero cure time lamination enabling immediate time to market; allows high performance application such as retort; is sustainable with low environment impact; and east of use for non-experience flexible packaging converters or label converters.

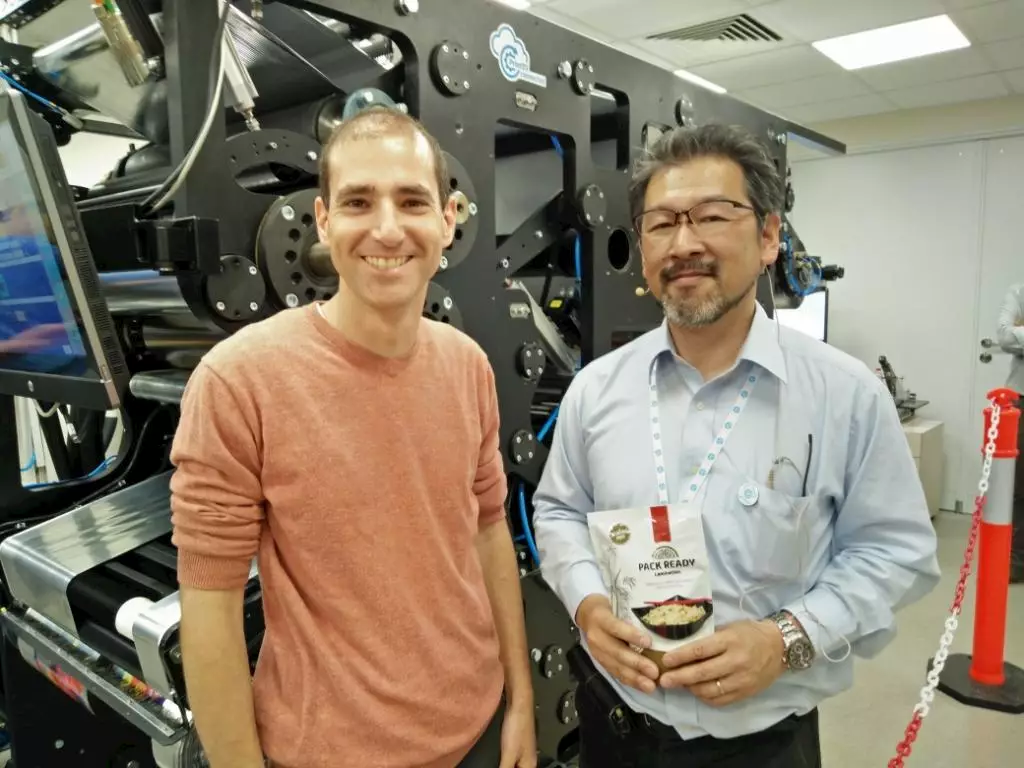

Salant (l) and Mach Machikawa (r), segment manager for flex packaging

The resin used in the technology is a thermoplastic polymer layer, which is coated on the laminate to produce a thermo-activated laminate. “During the lamination process, under pressure and heat, the special Pack Ready film melts and mechanically bonds (entangles) with the HP indigo printed film creating strong and instant lamination bond strength which is maintained over time.”

The aluminum barrier is used for protecting the food inside the package from oxygen and moisture, but Salant claimed that the Pack Ready technology can be applied to all types of films including Al barrier structures. “The secret is in choosing the best resin, optimized for HP Indigo ElectroInk and applying it on variable film.”

Karville is the first to announce Pack Ready partner that will develop the Pack Ready laminator. HP will announce the Pack Ready film supplier soon. The Pack Ready technology can be installed inline with the HP 20000 and will be commercially available in 2017.

See All

See All