EskoWorld exhibit will demonstrate the benefits of combining Asahi Clean Transfer Technology with Esko Crystal technology for the better OEE and productivity.

Stephan Doppelhammer, Asahi Photoproducts Europe Business Development Manager said, “By partnering with Esko, we bring together solutions from two world-class companies to create a faster, more efficient and more consistent workflow in flexographic platemaking.”

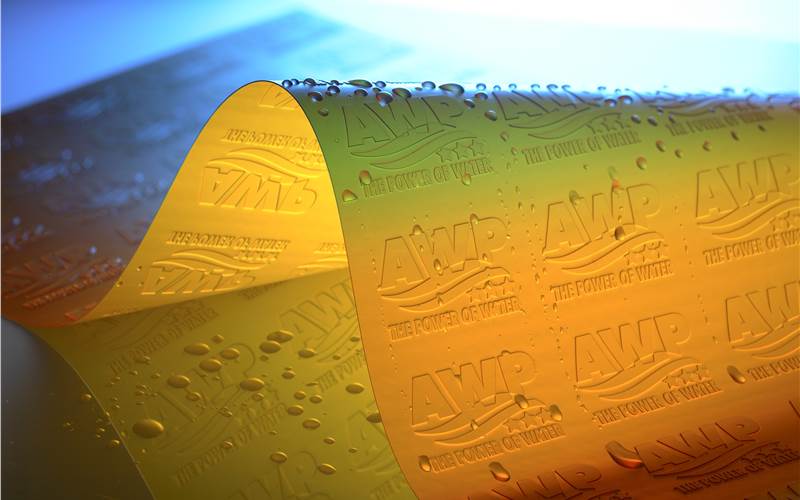

“By adding Asahi’s AWP water washable plates with Clean Transfer Technology to the mix, Asahi and Esko customers can take OEE to a brand-new level of efficiency while boosting print quality and reducing their environmental footprint,” continued Doppelhammer.

Clean Transfer Technology from Asahi enables a clean ink transfer and prevents ink accumulating on the plate surfaces and shoulders in screen areas. This leads to fewer cleaning intervals and reduced press downtime, as well as significant quality improvements.

Doppelhammer said, “Esko Equinox is ideal for converting separations to fixed palette printing, while Esko’s Crystal technology reduces the number of platemaking steps required and is making the process more consistent.”

Gateway Packaging from North America recently restructured its entire platemaking process with Asahi Photoproducts solutions. Tharrin Akers, the company’s prepress manager, said, “When running the Asahi AWP Clean Transfer plates, we were able to run the press at a 17% higher speed from 426 m / min. to 500 m / min and only had to stop for plate cleaning once consuming only 20 minutes. The result was a total production time of 7.2 hours instead of 11 hours, an astonishing 53% improvement in Overall Equipment Effectiveness (OEE) over our previous process.”

See All

See All