Managing colour is one of the most complex and challenging aspects of producing a quality press run. But GMG is making it easier than ever for 104 Indian print firms at their 150 locations to ensure colour is consistent and accurate wherever it goes.

In Indian scenario, print firms who prefer colour managed workflow are those who print for international print buyers or those who cater to premium jobs where colour accuracy is important.

GMG’s customer base is remarkable. From design and pre-media houses like Comart, Diadeis Alia, Schawk to offset printers like Pragati, Manipal, Parksons Packaging, Kamsri, SilverPoint, Shreedhar, Vishwakala; and from newspaper companies like Lokmat, Dainik Bhaskar, Sakal, Mathrubhumi to flexo and gravure converters like Betts India, Ryenders, Uflex, ITC, Huthamaki (PPL) – top names in each segment have entrusted GMG to achieve colour accuracy.

Afsal M Kottal, the business director of Percept Print Solutions, who are suppliers and partners for high-end colour management software GMG in India, said, “As markets develop, the need for workflow automation, colour management and marketing services is expected to rise.”

The key modules that the Indian print firms have deployed are GMG Colorserver Ink Optimizer and GMG Proofing Bundle, which help boost efficiency and save ink, reduce waste and operator time by automating and standardising colour spaces across devices. “What it does exactly is that it increases the company’s confidence in providing "right-first-time" print results and consistency between machines,” adds Kottal.

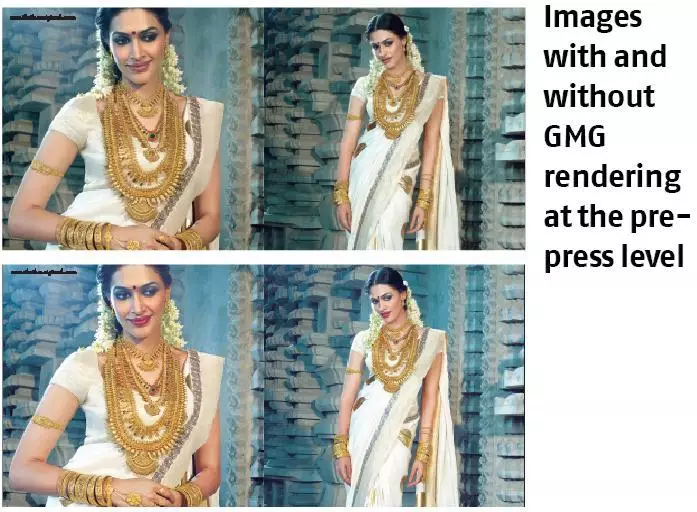

GMG Color Server is at the heart of GMG’s colour solutions. Kottal informed, “GMG works on the concept of colour remains same wherever its printed, meaning the brand colours and images look same in colour when it prints on coated paper, woodfree, newsprint, packaging boxes, digital print, large format etc.” It ensures that colour remains as close as possible to coated paper results (ISO39 or Pacspace) irrespective of paper type and process.

“Quality control has to start from pre-press and extend to proofing, CTP, printing and viewing conditions,” added Kottal. “For colour measurements, the basic requirements include a plate reader, a spectrophotometer, a densitometer and if possible an add-on CIP3 and closed loop solution. This helps printers to ensure colours will be as per clients expectation before the plates are made and run with standards and meet clients expectation every time with minimum or no operator’s colour expertise.”

Kottal felt that it is important for a print firm to understand the current production performance level and set key point indicators to implement continuous improvement in the process and review the shop floor data.

See All

See All