'We are going to take over the world'

Bengaluru-based textile printing specialist Quenby Transfers India, the wholly owned subsidiary of Quenby Transfers, UK, the winner of the PrintWeek India Company of the Year for 2014, is bullish. The manufacturer and exporter of heat transfer prints works in the textile printing segment, with a clear vision of where they want to go. Ramu Ramanathan talks to David Hunt, MD, and Sachindranath Udupa, operation director of Quenby Transfers, about the company’s ink compliance policies, its spe

25 May 2015 | By Ramu Ramanathan

Ramu Ramanathan (RR): Three good years plus the PrintWeek India Awards for Quenby?

Ramu Ramanathan (RR): Three good years plus the PrintWeek India Awards for Quenby?

David Hunt (DH): We have had phenomenal three years. We re-checked the monetary responsibilities and focused on the marketing of the company for the future, since things don’t happen overnight. In the last two to three years, our marketing strategy has taken us beyond our common territories, doubling our customer base in different product areas. Last year saw heavy capital investment by us. This year too, we will continue to invest heavily, as we are focusing on expanding our existing product and customer base. We have a clear vision of where we want to go. It’s not an investment in equipment, but an investment in people at all levels, from the shop floor to management. We are looking for people with particular skill sets because the chemistry of this industry is getting more and more intense and it needs people of specialised skills.

RR: In real terms, what do you mean when you say the chemistry laws are getting intense?

Sachindranath Udupa (SU): Chemical control is the key, since we deal with the European market. Every year, they add many new chemicals to their restriction list and we have to change our ink system accordingly.

RR: Please explain…

DH: Three years ago, there were around 50 chemicals in the restricted list of REACH (Regulation on Registration, Evaluation, Authorisation and Restriction of Chemicals, implemented in 2007, which streamlines and improves the former legislative framework on chemicals of the European Union). Now, the list contains 138 chemicals. There are talks about adding around 161 chemicals in the list. Everything that is not user-friendly has been taken out of the ink and it is being replaced with something else. This has an impact on the performance of the transfer, so you have to analyse it quite critically.

RR: So, typically, who does it? Are things like rheology and ink deposition tests done in-house or you outsource it?

DH: A majority of our products end up in the European market. Hence, we have to comply with their market requirements. A majority of our inks do come from European sources, so we know that the inks we buy would comply with European standards. That’s a kind of a safety net for us. The actual mixing of the ink is a secret recipe under this roof. The recipe is confidential, but all the ingredients comply with European regulations.

SU: When we started in 2008, we had eight customers. Six years later, we have 140 customers. It is more than just double per annum. Two years ago, we started supplying to Cambodia and this year to Indonesia. We want to expand to other countries in the region and increase our output for our existing customers.

RR: What are the new segments you are eyeing, like children wear and sportswear...

SU: Our sportswear section is in the initial stages. We are working towards increasing our share in the sportswear market. These days, we are doing more work in children wear and ladies wear sectors. It accounts for 90% of our output. We started doing sublimation two years back. This is picking up.

RA: Sublimation means direct transfer…

SU: No. It’s a different technique.

RR: How does it work?

DH: The back is made of white fabric. So, you have a sheet of paper with printing dye. The paper is kept on the white polyester. When heat hits the paper, the dye gets converted into gas and the gas forms a chemical bond with the polyester fibre.

RR: What about the process workflow? What is the gestation time in terms of pitching to superbrand like Nike and providing product prototypes?

SU: If I get a design from Nike, we will re-submit the design within five days to Nike. Sometimes, it gets rejected and designs are altered and resubmitted. Once a design is approved, we communicate the projected time and quantity for the order to the client and the production department will block the capacity for that particular product.

RR: So is it comparable to printing of book titles, with different editions? Or is it bulk orders?

SU: Bulk orders. The system is there to help us in delivery.

RR: You mentioned you turnaround in five days. Do you look at the fabric apart from the design?

SU: No.

RR: But doesn’t fabric play a critical role? I looked at the fabric which is produced in Tirrupur. Almost all of it has a different material.

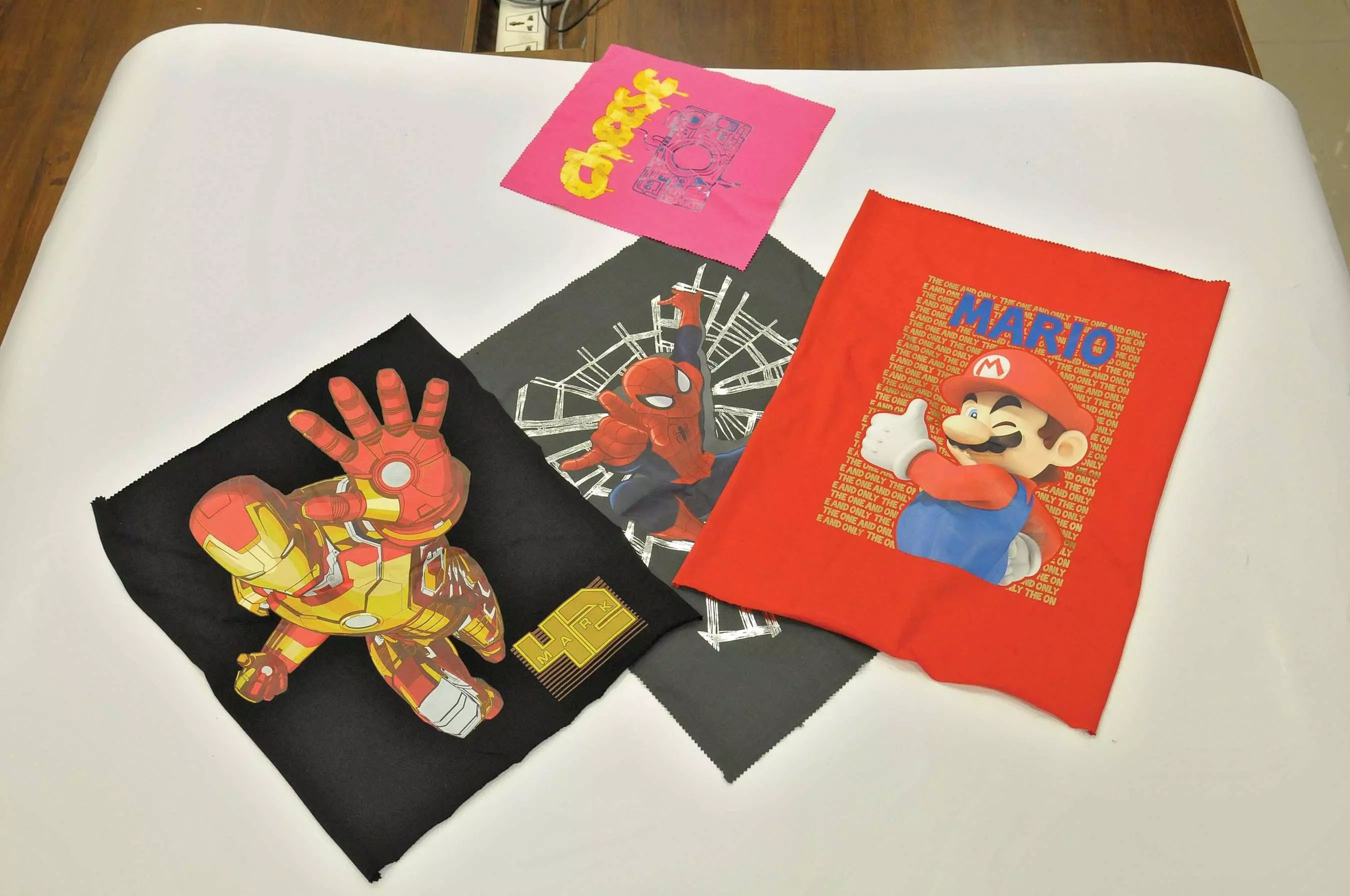

DH: We have to engineer transfer according to the fabric and its requirements, depending on whether its children wear; nightwear; pyjamas or underwear. This is especially important for licenced characters because of the photography imagery and the number of colours and their consistency that has to be maintained. This has been developed over the years. Now, we are into all sorts of garments, some of which require embellishment.

RR: Today, children wear is majority of what you do.

SU: Historically, this area of the garment industry has been pretty recession-proof. Kids like to wear things that they see in the movies and on television. Harry Potter, Donald Duck and other Disney characters are really popular amongst kids. We also get business when films are released, but it actually starts when the teasers come out. For example, the big trend in 2014 was the Disney movie Frozen. There is a lot of potential for this market .

RR: I saw the merchandising of the English football club Manchester United at your display centre. So, is this going to be on your mandate (targeting big sports clubs in Europe?)

DH: No. We don’t go and knock on people’s door. We actually have a relationship with garment suppliers who bring us jobs like Manchester United. Although we supply to Marks & Spencer, they don’t pay us any money. However, we have a very good working relationship with retailers in terms of technical advice, etc. We are accredited by George Asda in UK, which is part of the Walmart family. Its head office is in the UK, which is very close to where I live. So, we are nominated suppliers.

See All

See All