Spotlight on Asaies Automation's Acercon Color Registration System

Priya Raju looks at the Made in India Acercon which is a register control system built by Asaies in Kochi. The high speed camera system and control unit with real-time data processing impresses the packaging technologist and print expert because of its quick response and instant registration. Her verdict: it minimises waste during start-up and also through the print run.

29 Mar 2017 | By Priya Raju

Rajesh Kumar of Asaies Automation is quite clear about why India needs a robust colour registration system like Acercon Color Registration System. He says, while top-end printers in India use auto registration systems in their presses, the small and medium segment printers mostly rely on skilled operators for maintaining the colour registration. Kumar feels, automation was not considered by most of printers due to the high cost of the auto registration system, availability of cheaper labor and not so quality conscious customers. But now that seems to be changing. The humble Indian print firm is transforming itself.

Rajesh Kumar, who heads a nifty op for Asaies Automation in Kochi has been engaged with Indian web portal and e-commerce sites (www.manoramaonline.com, www.

Who are the customers?

Today, the Lokmat Media, ABP and Manipal Technologies at Mumbai, Pune, Jalgaon, Nanded, Kolhapur, Nagpur, Baharampur, Kolkata and Manipal locations. Kumar says, "Asaies can integrate our system with any press currently not having an auto registration system and on any press."

The system can be installed in manual presses (i.e. without registration motors) with necessary technology up gradation/motorization. The Asaies Automation team have developed a high precision web guide system which has been installed in a Harris Press at Malayala Manorama in Kottayam.

What does the software do?

In conventional offset printing, perfect colour registration and print quality is important. While printing an image that has more than one colour, it is necessary to print each colour separately and ensure each colour overlaps the others, precisely. If this is not done, the finished image will look fuzzy, blurred or out-of-register and the copy become waste. To help line the colours up correctly, a system of registration is necessary. As most newspapers in India are opting for all-colour, there has been an increased need to monitor colour registration in print. Advanced colour registration at full press speed is essential for today’s newspaper printer to achieve excellent print quality and stay ahead of competition. Achieving the saleable copies in minimum number of impressions is the key. This is even more critical for printers who are faced with shorter and more frequent press runs. Therefore, it is very important to maintain precise colour registration during start-up and throughout the print run to and ensure maximum waste saving and quality in print.

What market is it aimed at?

Anyone desirous of high-quality print. Top publishing houses in the country deploy old auto registration systems on their presses without the desired outcome. The factor preventing them from repair or upgradation is a huge investment. Plus there are mid-sized printers having manual presses with no motorisation who are intimidated about installing an auto registration system. Asaies Automation, who define themselves as "a young automation company" has been addressing the concerns of this market segment. The technically advanced and highly affordable auto registration system – Acercon is helpful for all types of operators.

How does it help a press operator?

Today, retaining skilled operators and depending on them for top print quality is not feasible in this highly competitive industry. One reason is, even if the operator is highly skillful, the consistency cannot be guaranteed as even the slightest delay in response can affect print quality and lead to waste in high-speed printing.

How does it work?

High-speed presses run from 35,000 to 80,000 copies per hour. This means nearly 10 to 20 copies per second. Scanning each copy to analyse and maintain perfect registration throughout the print run is possible only with high-quality image sensors, high precision controllers and highly intelligent and responsive software often leading to the high cost. This is what Acercon Color Registration System aims to do. Interestingly enough there is version for low speed and high speed

What is the USP?

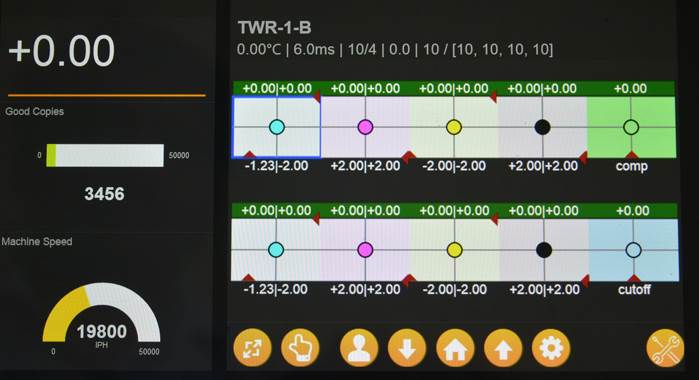

When PrintWeek India studied the product at the Lokmat plant, the stand-out features were: its circumferential and lateral colour register control; quick response with concurrent motor controls; high performance camera/sensor and optics; robust performance and waste saving even during low colour density and waste saving during low colour density; camera or sensor-based cut-off control.

What makes Acercon unique is its user-friendly and configurable operator console. This enables set offset values.

Technical specifications |

|

| Camera/sensor | High-Speed CMOS/CCD sensor |

| Camera resolution | 0.01mm |

| Illuminating | Maintenance-free LED-flash-unit integrated into camera housing |

| Mark area | Variable, min. 14 mm x 6 mm, Standard 20 mm x 10 mm |

| Field of view | 25 mm x 15 mm |

| Mark diameter | 0.1mm to 1.0mm |

| Measuring accuracy of colour register (web-based) | 0.01mm |

| Capture range of colour register (web-based) | ≥ 8 mm |

| Max number of marks per mark field | 10 |

| Max operating speed | 41.8 m/sec, 8226 ft/min |

| Maximum controlled units | 255 |

| Extendable no of printing units | 20 |

| Suitable materials | Paper, cardboard, film (transparent/opaque) |

| Data exchange | Ethernet/Wi-Fi |

| Display | Touch Screen Monitor |

What about ease of ops for the operator?

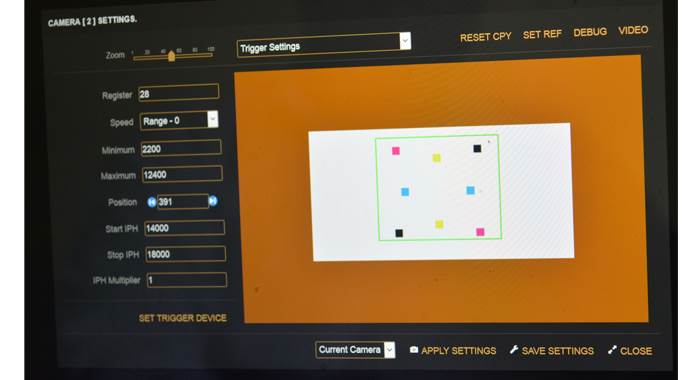

The operator console has been designed with high degree of flexibility in configuration and settings including that of camera/sensor and encoder. All relevant information like detection, motor positions, temperature, density, camera/flash LED status, control status etc are shown in the operator console for a quick view.

Settings including camera/sensor and encoder

What functions does the console have?

The new operator console integrates functionalities like registration control, cut-off control, compensator and web-guide control with single or multiple sensors. These are highly user-friendly touch-based with a "Graphical User Interface" that is accessible through LAN/Wifi in new generation devices like Mobile/Tab etc. The operator console is configurable and Asaies Automation can split the console among multiple operators with specific tower/sensor allocation. The operator console has advanced setting options for the sensor and other parameters.

operator console has been designed with high degree of flexibility in configuration

Is operations handsfree?

Rajesh Kumar says it is a 100% handsfree ops; and the system does not require any operator intervention during startup. Of course, if there is a need change in offset or environmental parameters one has to step in. The system gives relevant alerts to the operator if there is any intervention required.

Functions integrated in operating interface

• Administration of production parameters

• Camera/Detection settings

• Register status display

• Camera live picture

• Register fine adjustment

• Input of print mark geometry

• Trend display

• Measured value archive

Waste Saving: For a 2 mm correction at @15000 IPH, registration will be achieved within 120 sheets (Assuming motor takes 10 sec for 2 mm movement)

See All

See All