Protolab re-shapes the value of industrial printing

In interview with Sanjay Mehta, managing director of Protolab Electro Technologies. Mumbai-based Protolab manufactures printed electronics and human-machine-interface and use of printing machines, colour matching, laser systems, die-cutting and laminating processes combined with environmental life cycle testing.

24 Nov 2017 | By Shripad Bhat

Tell us about your recent expansion plans?

Since we are a quality driven company, we started getting orders from large companies and MNCs and also export orders. Hence there was a need to have a larger space to cope with the quantum jump in demand. We shifted to a new premise with 30000 sq.ft area in Navi Mumbai.

What is unique about your expansion?

We have acquired new facilities and we have set up additional 10000 sq/ft of clean room factory. In this factory, we have manufacturing facility for auto and white goods industry products.

When was your latest investment in screen printing machine?

We made our first investment in advanced screen printing in 2006, and then in 2010, and now in 2017.

How many machines do you have?

We have over 24 semi-automatic screen printing machines from Grafica and a fully automatic imported screen pritning machine, post-press equipment and allied accessories. Such advanced technology ensures quality and repeatability.

What is your perception about screen printing?

Today, a lot of advancements in technology is available worldwide in screen printing. Small printers, who have mostly manual set up, may find it difficult to adapt to the new technologies initially. In order to meet the dual requirement both quantity and quality - of print buyers (especially reputed brands), screen printers will have to move into automation or semi-automation. With the fast drying technology, better screen making, improved colour management systems, printers are able to achieve high volume, high quality with low price which the print buyer demands today.

Have you thought about investing in digital inkjet for industrial printing?

Yes, we invested in an HP Indigo but only to take care of variable data which is required in our photo ID and packaging line.

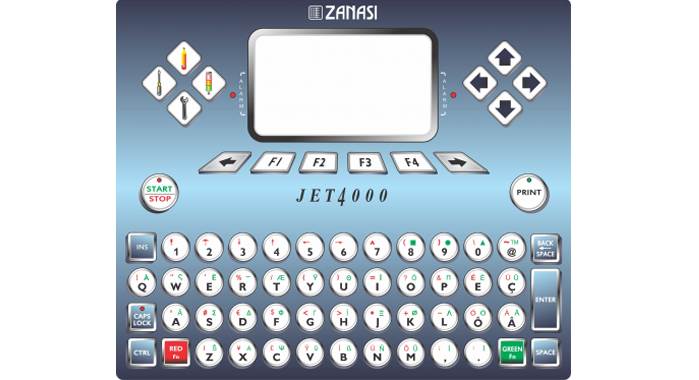

CAD sample of the product

What changes have seen in the world of industrial printing?

From printing on aluminium and acrylic engraving, the market has evolved. Textures and finishes, form and shape, colours and definition are in demand today. Plus there are the ever-increasing complexities of specifications.

What is the importance of quality in industrial screen printing?

Due to cut-throat competition, the print buyers demand quality print output from the print solution providers. This fact forces printers to move from manual to automatic. One may also try to offer low priced products by using low priced input. Use of low quality input will only produce low quality output at a cheap price. Today, customers are quality conscious and they do not mind paying a premium if the product is of a high standard. We do not compromise on quality.

What types of materials do you work with?

We believe in using finest materials like polycarbonates, polyester, polymers, for laminating and mounting layers, conductive paste, glass epoxy copper clad for the PCB, etc. Our aim is to give our customer nothing less than the finest and the best. We are committed to manufacturing products with a high degree of quality and reliability coupled with competitive price.

What are the quality measures adopted by your company?

We have implemented ISO 9001-2015. The global quality standards which are in process, namely ISO 14001 and the upgraded TS 16949 standards. These are required to match customer requirements. Manual operations in screen printing is labour intensive as a result of which turnaround of jobs was very slow, and hence achieving faster delivery was not possible. More so, in the kind of industrial job that we handle which involves multicolour printing. Besides, there used to be higher rejection due to dust settling down on the jobs kept for drying. With the advent of automation, all these problems are now solved. These days, we offer faster delivery of products with consistent quality, reliability and efficiency.

Are Indian printers at par with global standards?

Yes. India is producing to global standards but primarily it is focused on small volume niche market segments. I feel, if we automate and train our human resources, we can captivate the world beyond - and dazzle what the eye can perceive.

What are the industries catered by Protolab?

Protolab caters to the electronic, electrical, industrial automation, medical, defence, aviation, naval, automotive and the appliance / OEM manufacturers.

Which are the growth areas?

The automotive, medical and defence sectors are very promising; the industrial automation and electrical and electronic sectors are also equally encouraging.

Why do you say so?

The ‘Make in India’ initiative is not only an invite to the world, but also it has actually created infrastructure development opportunities and indirectly benefits the MSME. Further, with our talent pool of young skilled Indians, we are the destination to the world for value addition. This should be India’s main focus.

Your markets?

Besides the Indian market, we export our products to USA, Europe and Thailand. Our domestic and export market ratio is: 78:22.

Your company’s YoY growth:

We are averaging a 20% growth year on year and with the latest investment strategy we should add to a 35% growth and then maintain the year on year average.

What is the future of industrial printing in India:

It is here to exist. The demand shall increase as customer demands and product challenges will strive for perfection in opacity, definition and vibrancy of colour.

Your views about ‘knowledge’ and training in industrial printing?

Without knowledge there is no wisdom and without experience no expertise. Therefore knowledge is a combination of both and it co-exists.

How do you translate this into reality?

We believe in interactive participation and invest in training all through the year. We have programmes for self-development, team development as well as skill enhancement. We do group exercise of push and pull where team members are expected to perform the task of the preceding or subsequent department. This brings a lot of understanding of the challenges in task fulfilment. It's always important to understand from another's perspective too.

Your message to the screen printers doing industrial jobs?Our Protolab team believes in ruling tomorrow. We are passionate to deliver beyond endless possibilities and making impressions wherever you can imagine. Similarly, there is no replacement to screen printing, digital can cater to a market other than what industrial screen printing requirements. One must elevate and automate to print a perfect in every print. India has values and India is the value-added destination to the world. ‘Strive for perfection will at least help one in achieving excellence’.

See All

See All