Problem cases in the pressroom

Bernd Schopp, director, Print Media Academy offers advice on tips in the most common problem cases.

18 Apr 2013 | By PrintWeek India

Electrostatic Charge on Paper

Printers are familiar with the prob- lem: printing sheets stick together because they are electro-statically charged. The result: several sheets are simultaneously sucked in from the stack, stopping up the feeder. Static electricity arises from either an electron deficit (positive charge) or an excess of electrons (negative charge) on the surface of the paper.An electrostatic charge is especially likely to occur when paper that is too dry is processed under conditions of low atmospheric humidity. The critical lower limit – as much for paper dampness as for relative humidity – ranges from 40 % to 42 %. (Electrostatic = immobile, i.e. static electricity)

Printers are familiar with the prob- lem: printing sheets stick together because they are electro-statically charged. The result: several sheets are simultaneously sucked in from the stack, stopping up the feeder. Static electricity arises from either an electron deficit (positive charge) or an excess of electrons (negative charge) on the surface of the paper.An electrostatic charge is especially likely to occur when paper that is too dry is processed under conditions of low atmospheric humidity. The critical lower limit – as much for paper dampness as for relative humidity – ranges from 40 % to 42 %. (Electrostatic = immobile, i.e. static electricity)

Remedy

- The moisture content of paper should range between 45 % and 55 %. The electrical conductivity of paper, and consequently electrical run off, increases with increasing moisture content.

- Working spaces should be air-conditioned or humidified at a 50 % to55 % level of relative humidity. Particularly during colder times of the year in heated rooms, the atmospheric humidity can sink dramatically.

- Antistatic equipment such as discharge electrodes and ionic blowers reduce electrostatic charge; ionization equipment raises the surround- ing air’s electronic conductivity, thereby preventing the build up of static charge.

Crease Formation

During printing, creases are often generated on paper that is poorly air-conditioned, or does not lie in a flat plane, as well as from paper that is wavy-edged, baggy-centered, or statically charged. Incorrect settings on the sheet-feeder or during paper transfer may also lead to the formation of creases. In order to ensure that the printing stock during the printing process lies flat, it should be kept properly air-conditioned during storage and transport. Paper is very sensitive to fluctuations in humidity. This is why one must be careful to maintain atmospheric humidity and tempera- ture at constant levels during storage. Paper should demonstrate a relative humidity from 50 % to 55 %; the temperature should be constant between 20 °C and 22 °C (68 °F and 71.6 °F)

Should creases develop, this may also be the fault of incorrect machine settings – most likely on the sheet-feeder. Among the reasons creases may form are incorrectly set or jamming front lays, side lays that draw with too much force, a hold-down device that has been set too tightly, or an air-blast that is too strong. An incorrect air-pressure setting at the point of sheet transfer may also contribute to the formation of creases. Further sources include poorly functioning or dirty grippers, which warp the sheet, as well as a printing pressure between the rubber and the impression cylinder that is set too high, or is uneven. This tumbles the sheet, and will result in creasing.

Remedy

- Employ printing stock that is good and flat

- Inspect the front lays

- Inspect the side lays

- Do not set the hold-down device too tightly

- Reduce the air-blast on the sheet-feeder

- Optimize the air-pressure adjustments at the point of sheet transfer

- Optimize the print lateral feed

- Inspect, clean, and adjust the grippers as needed

Picking

Picking occurs when small particles are torn out of the surface of the paper, or printing stock rips during the printing process. This can cause damage to the printing blanket. It becomes necessary to wash more frequently, and print quality is adversely affected. Picking becomes a problem when surfaces are not sufficiently resilient. This indicates that the tractive force of the printing ink is greater than the fiber adhesion in the paper structure, or the bonding of the pigment used in the coating. Inadequate gluing, or the poor anchoring of the coating material on the paper’s surface may cause picking.

Remedy

- Employ a soft series of inks

- Reduce the ink’s tractive force (add printing oil)

- Allow the machine to run on standard working condition

- Raise the rasp temperature (temper the inking system)

- Reduce the speed of the machine; this lessens the traction on the paper

- Use a quick release blanket

- Employ paper of better quality

Emulsification

Emulsion is a mixture of ink and dampening solution. In this process, dampening solution is distributed evenly throughout the ink in small drop- lets. The proportion of water in a “stabile emulsion” is around 20 %. If higher, then the ink’s splitting properties are reduced, and the ink flow is interrupted. As a result, the emulsion becomes unstable, the ink “builds up”, and it “emulsifies”. Too large a proportion of dampening solution in the printing ink, or too low a pH-value fosters emulsification. Printing inks react differently, depending on what type they are: blended inks, dayglo, or metallic inks are more sensitive than inks in the normal scale. Emulsi- fied printing inks will increase drying times, as well as increasing the risk of deposits.

Remedy

- Set the ink and dampening balance correctly, and check on it continuously throughout the printing process.

- In case of emulsified ink, wash the rollers, and re-establish the smearing limit.

- Check the dampening solution, and change it regularly (the ideal dampening solution has a water hardness from 8 to 12° dH, a pH-value from 4.8 to 5.5, and a temperature from 10 °C to 15 °C (50 °F to 59 °F).

- On an Alcolor dampening unit: separate the intermediate roller from the inking unit; install cross-flow ventilators.

- Avoid frequent phases of pre- and post-dampening (during make-ready or stoppages).

- Inspect and optimize the adjustment of the inking and dampening rollers.

- Where there is less ink taking, an additional ink stripe may be introduced to stabilize the balance of ink and water.

Ghosting

By ghosting, one understands a circumstance where printing form elements other than the desired positive or negative ones duplicate themselves onto the printed surface. These “stencils” or “ghost images” emerge from repeated passes of the ink form roller over the plate cylinder, and from a reduction or accumulation of ink. Used (hard) or poorly adjusted ink-rollers facilitate ghosting, and the tendency toward ghosting increases with weak pigment inks. An optimal balance between ink and dampening solution helps prevent ghosting, since too much water negatively influences printing outcomes.

Remedy

- When maintaining rollers, only use the appropriate cleansing agents; a weekly application of wash paste removes lime deposits, and will regenerate the rollers.

- Adjust the rollers in accordance with the instruction manual; inspect the adjustment regularly.

- Change used rollers: the rubber surface of older rollers will become glossy and over-smooth. At the same time, as their hardness increases, the edges bulge out in a trumpet shape. More pronounced abrasion becomes evident.

- Adjust for maximum lateral distribution

- Adjust reciprocation of the ink form rollers

- Shift the engaging point of the lateral distribution

- Reduce the quantity of dampening solution being used (smearing limit)

- Employ high pigment inks

- Turn on the vario

- Turn the printing form (prepress)

Mottling

When speaking of “mottling” or “back trap mottling“, printers are referring to a cloudy print output. The problem originates in paper that is partially uneven, and the resulting uneven absorption and back split characteristics. If the paper is spotted, or if a certain amount of cloudiness is already present in the coating, then the printing ink will be only partly absorbed. In four-colour sheetfed offset printing, the printing result will back split on the printing blankets of the subsequent printing units. When an uneven penetration of printing ink is especially pronounced, this will become visible after the back split process occurs, as an uneven print reproduction. The problem of a “cloudy printout” manifests itself in the greatest variety in offset printing. In order to isolate the printing paper as the culprit, one must first determine if the visual appearance of the cloudy printout matches up with the paper structure. This can be done using backlighting, or under UV light. The absorp- tion characteristics of the printing ink on the paper in question can also be made visible by resorting to a simple wipe test using special wipe-test ink. In this way, the proof that paper is the root cause may be adduced.

Remedy

In cases where the cloudy printout is purely the result of the paper being used, the only solution is to change to an alternative type of paper.

Horizontal Stripes

The problem in this case involves disturbances in the printed image, which are manifested as bright or dark stripes running horizontally to the direction of printing.

Horizontal stripes arise for a variety of reasons. Besides adjustment errors, errors in screen vignettes (prepress errors) may also play a role. Additionally, the formation of stripes may also be influenced by contamination from the build up of powder and coating, from damage to the printing blanket or the printing plate, or from the ink/dampening solution feeds, as well as from the quality of the ink. The machines themselves may also be causing the stripes, for example from an incorrect alignment of the ink and dampening units, or from rolling errors (too much pressure). Tone stripes can be caused by the relative lateral movement of the rollers on the printing plate. Horizontal stripes arise for a variety of reasons. Besides adjustment errors, errors in screen vignettes (prepress errors) may also play a role. Additionally, the formation of stripes may also be influenced by contamination from the build up of powder and coating, from damage to the printing blanket or the printing plate, or from the ink/dampening solution feeds, as well as from the quality of the ink. The machines themselves may also be causing the stripes, for example from an incorrect alignment of the ink and dampening units, or from rolling errors (too much pressure). Tone stripes can be caused by the relative lateral movement of the rollers on the printing plate.

Horizontal stripes arise for a variety of reasons. Besides adjustment errors, errors in screen vignettes (prepress errors) may also play a role. Additionally, the formation of stripes may also be influenced by contamination from the build up of powder and coating, from damage to the printing blanket or the printing plate, or from the ink/dampening solution feeds, as well as from the quality of the ink. The machines themselves may also be causing the stripes, for example from an incorrect alignment of the ink and dampening units, or from rolling errors (too much pressure). Tone stripes can be caused by the relative lateral movement of the rollers on the printing plate. Horizontal stripes arise for a variety of reasons. Besides adjustment errors, errors in screen vignettes (prepress errors) may also play a role. Additionally, the formation of stripes may also be influenced by contamination from the build up of powder and coating, from damage to the printing blanket or the printing plate, or from the ink/dampening solution feeds, as well as from the quality of the ink. The machines themselves may also be causing the stripes, for example from an incorrect alignment of the ink and dampening units, or from rolling errors (too much pressure). Tone stripes can be caused by the relative lateral movement of the rollers on the printing plate.- When maintaining the rollers, only use appropriate cleansing agents; the weekly application of a wash paste removes lime deposits, and will regenerate the rollers.

- Adjust the rollers in accordance with the instruction manual; inspect the adjustment regularly.

- Change used rollers: the rubber surface of older rollers becomes glossy and over-smooth. At the same time, as their hardness increases, the edges bulge out in the shape of a trumpet. More pronounced abrasion becomes evident.

- Adjust reciprocation of the ink form rollers

- The dampening distributing cylinder must be kept clean and receptive to water.

- The roll bearings must be in fine working condition (no play, no sticking).

- Lubricate the roll bearings

- By setting the ink form rollers as gently as possible on the printing plate, impacts stemming from the run-on and run-off edges are reduced.

- The bearer ring should be kept clean and grease-free.

- The calibrated underpacking should be clean, cut in a format to fit, and correctly inserted.

- Clamping between the plate and the blanket should range between 0.1 mm and a max. 0.13 mm. (0.004 in and 0.051 in).

- Clamping between the blanket and the counterpressure should be set in consideration of the surface of the printing stock; avoid clamping that is set too high.

Darkening

When darkening occurs, the darker colors are transferred from the blanket over the printing plate onto the succeeding inking system, where they contaminate the light colors. During wet-on-wet printing, the tackiness of the inks must be coordinated. Nevertheless, it can happen that the darker colors from the first printing units contaminate the lighter colors (mainly yellows) in the latter printing units.

Remedy

- Change to a different kind of ink

- Deposit the lighter colors more in the direction of the sheet-feeder.

- Follow the rule of thumb “screen before surface” for the inking sequence.

- Raise the dampening solution feed in the lighter colors, or increase the lighter colors.

Decrease in Tone Value

- Normal plate wear and tear

- Coating build up or powder deposits on the blanket

- Unsuitable plate cleanser (admixture of abrasive material)

- A pH-value in the dampening solution that is too low may slightly etch the edges of the halftone dots.

- An alcohol content that is too high corrodes the ink-accepting coating.

- Rapidly volatizing cleansing solutions may damage the printing plate.

Remedy

- Employ appropriate printing plates

- Use a suitable plate cleanser and certified cleaning solution when maintaining the printing plate.

- Avoid using abrasive powder (calcium carbonate)

- Always prepare dampening solution according to instructions (pH-value, alcohol concentration); the ideal dampening solution has a water hardness of 8 to 12° dH, a pH-value of 4.8 to 5.5, and a temperature ranging from 10 °C to 15 °C (50 °F to 59 °F).

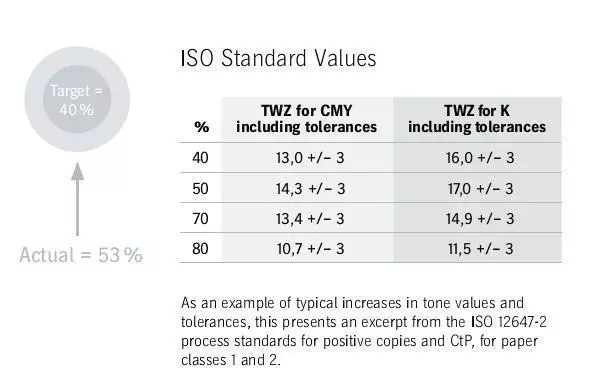

Increase in Tone Value

An increase in tone values means a gain in the halftone dot of the print compared to the original (film, printing plate). In order to establish an increase in tone value, a full tone field combined with a defined grid is needed. The problem of an increase in tone value may already arise during the preparation of the printing form. While an increase in tone value in a printing press cannot be entirely avoided, it should never be allowed to exceed a certain point. An increase in tone value depends on type of ink, ink quantity, the temperature in the inking system, the surface of the printing stock, the clamping, the blanket type, the dampening solution, and the quantity of dampening solution employed.

Remedy

- Print with a familiar ink series, if possible without additives, within the tolerance levels of your own standards of density.

- An increase in tone value (approx. 2 %) must be taken into consideration during black and white printing.

- Employ appropriate black and white inks.

- Set the inking system between 27 °C and 30 °C (80 °F and 86 °F)

- Avoid changing the printing stock during the print run

- Clamping between the plate and the blanket should be set between 0.1 mm and max. 0.13 mm (0.004 in and 0.051 in)

- Pressing between the blanket and the counterpressure should be set to reflect the printing stock surface; avoid setting compression too high.

- A fixed type of blanket should be used in the pressroom (standardisation)

- Only use certified cleansing solutions when washing.

- Wash new blankets with water after mounting in order to remove the talcum.

- Newly stretched blankets must be restretched

- Run the quantity of dampening solution slightly over the smear limit, and precisely maintain the balance of ink and dampening solution.

- Optically test the three-quarter tones with a line tester

- Check the printing pressure adjustment, and reduce as needed

- Maintain recommended packing thicknesses (control with a cylinder gauge)

- Mount the blankets carefully, and use a torque wrench when stretching

- Insert the blankets in the printing press in the indicated weave direction

- Clean the grippers and adjust them as needed

Remedy

- Optimal tuning between ink and paper (inquire with the manufacturer)

- Do not allow the pH-value of the dampening solution to cross below 4.7

- Avoid ink emulsification

- Only dose additives according to the manufacturer’s indications

- In cases of lower ink taking, also print ink stripes

- Avoid high ink film densities (employ ink reduction or high pigment inks)

- Use IR drying

- In order to rescue a print job, coat it with an oil or dispersion varnish

See All

See All