As most newspapers in the country go all-colour, there has been an increased need to monitor colour registration in print. Rahul Kumar and Dibyajyoti Sarma compare and contrast the technologies of the two international players in the field – Quadtech and QI Press Controls.

The companies

Headquartered in the USA, Quadtech, a leader in design and manufacture of control systems, offers the Quadtech Register Guidance System with Multicam, a closed-loop colour-to-colour register control system designed to work on its Icon integrated platform with other Quadtech products, including the colour control system, the ribbon control system, and data central reporting.

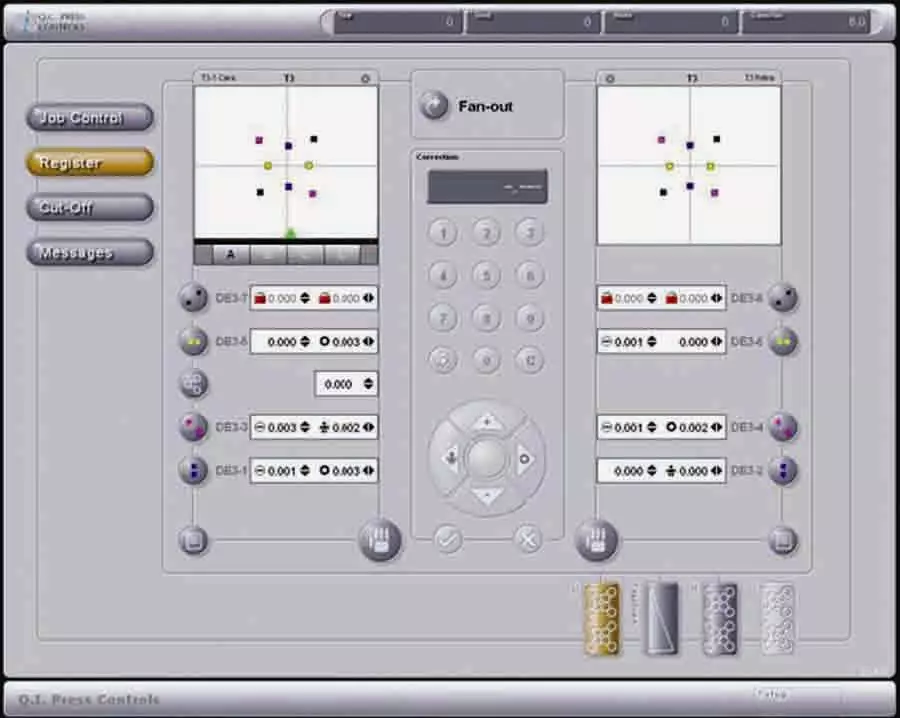

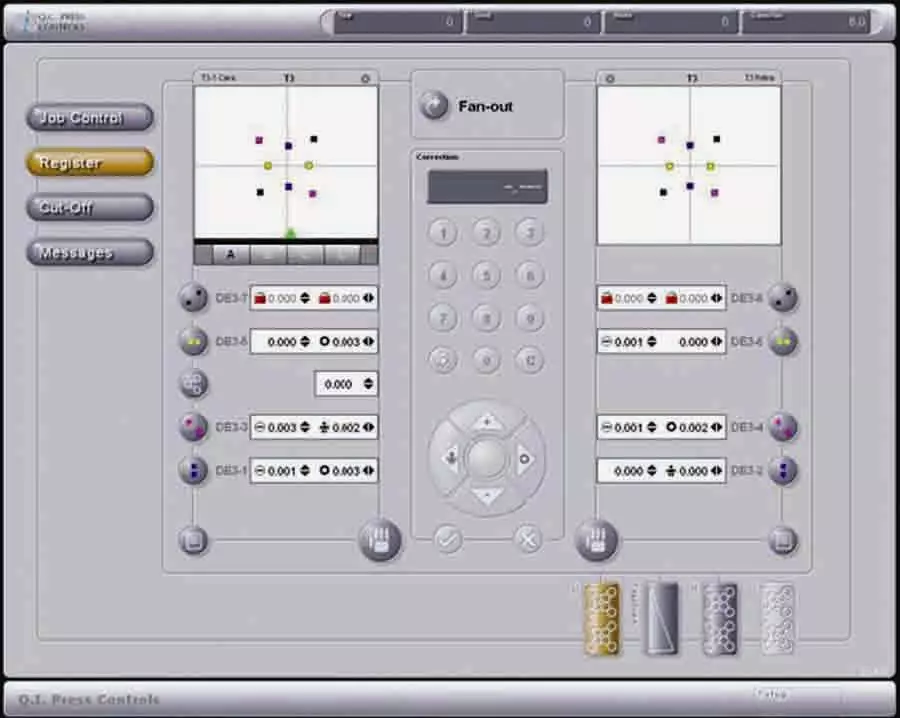

Established in 1996, the Netherlands-based QI Press Controls boasts of MRC 3D, a unique patented register control system with two digital cameras equipped with special optical design and build-in microprocessors provide real-time data processing of the measured data. Because of its 3D technology, MRC 3D scanner is capable of accurately measuring printed micro marks independent of deformation in paper web, tension or press conditions.

Reducing waste

The reason a newspaper house invests in a colour registration solution is to reduce waste. How effective, in reality, are the solutions? How about increased saving and maximisation of quality? The answer is simple. Advanced colour registration at full press speeds is no longer a “nice to have” part of the process. It is essential for today’s newspaper printer to survive and thrive, says Hemant Desai, general manager of Quadtech India. “Waste reduction and increased savings are realised by achieving saleable copies in a minimum number of press impressions from start up. This is even more critical for printers who are faced with shorter and more frequent press runs,” he says.

According to him, the Quadtech Icon integrated platform reduces operator involvement by not only making automatic adjustments during the press run, but also by greatly streamlining job setup by providing instant access to preset parameters for all their saved jobs. “Another benefit of our suite of systems is the ability to closely monitor and improve press performance through our data central reporting module. Besides quickly identifying problems on press, the reports can serve to show customers the precise extent of any quality issues – ensuring that you will be credited for the actual quality of your work,” says Desai.

Since printing is a dynamic process and can be influenced by various variables like paper quality, tension of the paper, temperature, humidity etc, constant monitoring and control of the registration is needed to maintain the print quality with minimal wastage, says Vijay Kumar Pandya, chief executive officer, QI Press Controls. “Therefore, besides reducing the wastage, MRC 3D increases savings of inputs, like up-time of press, operators’ efficiency, as well as helps in achieving consistent print quality,” he adds.

MRC 3D camera ensures fastest detection of register marks

The camera

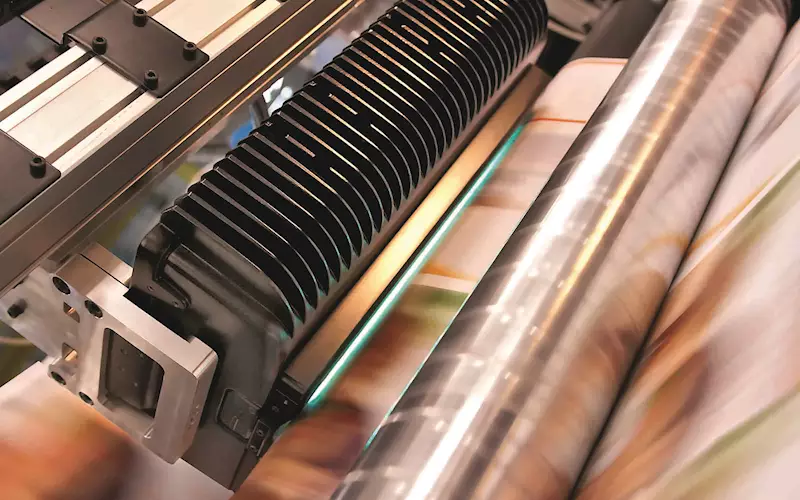

Of course, in the entire operation, the camera plays an integral role. For QI Press Controls, the camera is the heart of the MRC 3D register control solution. “With its high-speed measurement technique (40 pictures per second), high resolutions and patented optical technology, MRC 3D camera ensure fastest detection of register marks and hence achieve the register in shortest possible time and maintain it throughout the production run,” says Pandya. “Hence, MRC 3D ensures that register control is achieved quicker during start up of the print job and will be continuously monitored and controlled throughout the print run.”

Desai agrees that the camera is the most critical element of an advanced colour registration solution. He says Quadtech Multicam is performance-proven in the industry, with more than 10,000 cameras built. “One important distinction is that the Multicam is our proprietary technology, which relies not on off-the-shelf hardware, but on camera technology that we developed ourselves especially for the harsh environment of a newspaper press room.”

How about OEMs in its use? Desai says the Quadtech system offers the benefit of working through the OEM’s operator control station, and presetting camera functions from information from the press control network when integrated with OEM presses.

Pandya says QI Press Controls is working closely with almost all OEMs like, KBA, Goss, Manroland, Mitsubishi, TKS; plus the Indian manufacturers like TPH, J Mahabeer, Pressline. “Normally, the end-user decides the equipment. We have done installations on all kinds of newspaper, commercial and packaging presses,” he says.

One of the major issues of an Indian printing plant is the issues of environment, to put it bluntly, heat and dust. Is there any technology to clean the lenses from dust, which is the part and parcel of a printing press? “Each camera is fitted with an Ink Mist Shield (IMS) that protects the camera from contamination of the lens and the lighting. This removable glass simplifies the cleaning,” says Pandya. “Optionally, the camera can be fitted with an automatic ink mist shied (AIMS) system. This unique, fully-automatic arrangement keeps the optic clean by a driven foil.”

Quadtech, on the other hand, offers an Optiguard option, which uses a small amount of compressed air to keep the camera lens clean.

QI Press Controls’ products are designed on modular architecture

Team QI Press Controls: providing consultancy and support for upgradation of press automation

Using colour control

The printing process of a newspaper is the sum of many parts. There are newsprints, printing inks, web offset printing press and their speed, and most of all, the staff who will manage these parts. In this context, what are the hurdles for a colour registration system to operate smoothly? According to Pandya, there are no hurdles as QI Press Controls’ technologies take care of it. However, he adds, “In the present Indian circumstances, quality of newsprint, overused and lower maintenance of printing presses and sometimes skill of the staff affects the smooth running or best performance of register control system.”

Desai says the biggest hurdle for any registration system is the ability to identify register marks at high press speeds from within the vast amount of information flying by the cameras on a newspaper print run, and identify those marks as fast as possible so that register can be controlled. “Multicam’s proprietary design is such that it is able to search for those register marks 30 times per second, and quickly lock on to the marks so that control of the colour-to-colour register is achieved as quickly as possible. This saves valuable paper and ink as well as controls the quality of the publication,” Desai says.

Desai: “Automation opens new revenue streams”

Inside the technology

Now we focus on some technical aspects. What are the differences between circumferential and lateral colour register control? Do both work from single equipment? Which one is preferred? Desai answers, “Quadtech’s closed-loop register control provides both circumferential and lateral colour register control. Systems that only control one are missing an important element of quality control.” He says the demand for circumferential control is more prevalent as register errors in this direction are much more common due to paper stretch, tension issues, etc.

According to Pandya, variation of register in circumferential direction occurs due to variation in web condition resulting from tension, temperature, hygroscopic conditions, and physical properties. “Variations in circumferential register are always dynamic and in appreciable amount from print quality point of view,” he says. Lateral register variation is mainly due to expansion of the web due to application of ink and water on the web and due to grammage variation across the web, which causes wandering of the web in lateral direction. “Though it is more stable in nature, it is important to be controlled for achieving finer quality of printing,” he says.

With QI Press Controls system, both can be measured and controlled by one camera and single set of marks. “Obviously, both variations deteriorate the quality of prints and hence, controls together for both the variations are required,” Pandya says.

What must be the ideal configuration of printing presses at newspaper production houses to opt for a particular registration solution? “In designing the Multicam system originally, and in subsequent improvements, we approached the problem with the understanding that every newspaper printer has unique requirements,” says Desai. “It was important from the outset to design the system to be very flexible, easy to use, and affordable. As a result, we developed a system that handles the most complex press configurations and accommodates a variety of tower types, such as 4-over-4, satellite units, 5-over-5, 4-over-1, and shell-cylinder applications”

Configuration of press is decided according to the final product to be printed. Pandya says, for QI Press Control, press configurations are not restrictions. “In fact, due to simple architecture and less hardware, our system is adaptable to any type and configuration of web printing presses. We offer our solution in all configuration web offset presses. However, majority of our installations are on tower configuration presses,” he adds.

Does colour gamut (CMYK, RGB and RYB) play a role in the process of colour registration? Desai says there is no major implication of colour gamut, especially for the Quadtech technology of controls. For Pandya, the inverse is actually true. “The colour registration system plays a role in reproducing proper colours on a printing press. If registration is not controlled and the printing process is out of register, the colours may not be reproduced properly,” he says.

About identifying register marks, Quadtech’s Multicam can identify marks as small as 0,36 mm (0.014 in.), as well as RGS, Autotron, and other manufacturers’ marks at speeds up to 17,8 M/sec (3,500 ft/min).

On the other hand, Pandya says unlike other systems, the MRC 3D needs only 5x5mm print-free space, which gives lot of flexibilities for printers. “In fact, our latest system, IDS-3D, is a fully automatic image based colour and register measuring and control system for web offset presses that also detects failures in print. A digital camera ensures that the measured data is processed in real-time and uses the digital file data as its reference. The ultimate result realised by IDS-3D is reproduction with absolute colour and register stability in products independent of job, printing company or press at minimum waste and maximum,” he says.

How about the easiness of operating, installation, flexibility and affordability of the individual systems? Desai says Quadtech systems are designed to be very flexible and modular, allowing the printer to incorporate only the features that they need today, and add features such as fan-out control and anti-embossing as their budgets allow. This ability to add functionality in the future ensures that the initial investment won’t be wasted. He adds, “The operator user interface on our ICON integrated platform has several advantages. First, it is intuitive and easy to use with minimal operator training. Second, other Quadtech systems, such as ribbon control system with Multicam, data central reporting, digital ink system, and colour control and web inspection system with Accucam are based on the same ICON platform. When operators have used one Quadtech system, their interaction with any additional systems will seem very familiar. All Quadtech systems share the same job setup information, and there will be very little learning curve as printers continue to add levels of automation.”

QI Press Controls products are designed on modular architecture. “This means, the operating platform – graphic operating system (GOS) with large touch screens remains the same. Only functionalities of the system changes as per the applications employed. The user interface has features like page orientation, press orientation, problem reporting, remote diagnostics, etc. This makes the system, easy to install, easy to operate with minimum menus, flexible to add functionality without any modification at later stage, economical to modify or upgrade and easy to maintain.

Support and adaptation

What kind of printing presses these systems support better, indigenous or overseas? What about the complex configuration of the printing presses? Quadtech system is designed for all worldwide press designs from the USA, Europe, Japan, India, China and so on. “Our system is also designed to support the complex presses within the commercial and newspaper industries,” Desai says. Ditto QI Press Controls. “We did have installations on all type of configuration, which includes very complex presses which are built with different print units, multiple type of print units and multiple folders, etc,” Pandya adds.

What would a colour registration solution provider suggest manufacturers of printing presses, newsprint, printing inks, consumables and many other components like blankets and rubber rollers? Desai has no specific suggestion, as it really depends upon the manufacturer. However, he adds that over the years, Quadtech has helped press manufacturers in the designs of their presses as it relates to register controls, register motors, interfaces and industry knowledge that may be outside of the press manufacturers’ core business. “As Quadtech’s parent company Quad/Graphics is one of the world’s largest commercial printers, we understand printing better than most in the press controls industry,” he says.

According to Pandya, printing is a very complex process involving, mechanics, chemistry and many different inputs. The process is dynamic and even affected by the climatic conditions. Hence, to achieve the good print quality consistently, all the parameters have to be within prescribed quality standards. “In our opinion, quality of printing presses has possibilities to improve further and also, good quality newspaper prints will always play an important role in getting maximum benefits of our solution or any automation solution,” he says.

India is a land of geographical varieties. How does the colour control system tackle changes in temperature, humidity and other factors? “Supported by varied and extensive print experience of our engineers, our systems are designed to optimally compensate these factors and achieve stable and consistent results,” says Pandya. Desai echoes the same. “Quadtech has extensive experience with our equipment operating in the conditions presented in India. Our designs are verified for operation of up to 55 degrees Celsius where necessary,” he says.

Are there any special software or hardware you use in the solutions?” There are many options both in hardware and software for the system, depending upon the press design or upon the customer’s needs for printing operations,” says Desai. “Options for fan-out control, automated job setup, data reporting and many software options specific to presses or the customer’s needs are available.”

Pandya says though the mRC 3D is an embedded system with patented software and hardware, it can be interfaced with all presses and controls. “Customisation is easy and simple with our system due to its modular architecture. Moreover, we are member of Prime Group that gives us easy accessibility to various interfaces,” he says.

Does change occur when we take it colour to colour? What about focal distance and paper deformation? Since paper deformation, wrinkling, and web flutter are normal part of a print run, Quadtech mounts the Multicam near where the paper enters or exits an idler roller.

“This stabilises the paper and eliminates the inaccuracy of measuring on a fluttering web. Software algorithms can be used to try and compensate when measuring register over an unsupported web. But this method is unreliable because of the paper’s instability, and thus not nearly as accurate. Our Multicam lens is mounted at a fixed 30.5mm (1.2 inches) from the substrate. The Optiguard for keeping the lens clean is 7.8mm (0.31 inches) from the substrate,” Desai says.

Pandya says configuration of system changes as per the configuration of press and the functionalities required from the system. “When it is colour-to-colour measurement and control for one web being printed on 4-colours on both the sides, two cameras are needed for the application. If cut off too is required to be controlled for the web, an additional camera or addition of functionality in the existing camera is required. Likewise, for multiple webs and functionalities, cameras and controls are configured,” he says. The mRC 3D uses special optical technology which take care for fluttering or wandering of paper as well as deformation in paper due to web tension, etc. “Due to variable focal lengths of the camera, special rollers for stabilising the webs are not required. Therefore, installation of system on any kind of press is easier and better performance can be achieved irrespective of press stability and paper quality,” he says.

What is the light source? For Quadtech, the light source is LED, which provides many advantages over other traditional lighting options such as fluorescent and tungsten halogen. “The LEDs used by Quadtech are rated for up to 100,000 hours (almost 11-1⁄2 years), and using temperature controlled (active cooled) LEDs, the life span is maximised while providing constant, stable light intensity levels,” Desai says. QI Press Controls systems too use LED light of 130 lumen/watt.

While the Quadtech solution can control up to eight colours on each surface, the QI Press Controls solutions can be registered with up to six colours. With additional camera, more colours can be registered.

Advantages

Why should a newspaper publication house install the particular system? Desai quotes one of Quadtech customers, S Balasubramanian Adityan, director, Daily Thanthi, as saying, “The installation of the Quadtech systems benefits us in five ways: we can shorten make-ready times, reduce start-up waste, achieve consistent colour, and optimise labour and press usage, while also contributing towards a better product and increased readership.”

Desai adds that not only automation reduces waste and labour, and increases print quality, it can also open new revenue streams for newspaper printers, allowing them to pursue semi-commercial work, or approach customers whose quality demands cannot be met without advanced automation. “Most importantly, those who embrace the most efficient technology solutions will survive and thrive. Those who try to address today or tomorrow’s printing challenges with yesterday’s equipment or off-the-shelf solutions will not be able to remain profitable,” he opines.

Pandya says in competitive environment of the print market, globalisation and rising cost of printing, newspapers and commercial web offset printers will require minimisation of its operating cost to offer their print product most competitively. “In that case, our solution will help achieve these goals by reducing print waste, maximise the press operation with efficient operational efficiency and getting improved print quality consistently. The return on investment with our system is very fast because of its reasonable pricing, maximum waste savings and lowest running and maintenance cost. The ROI can be 12 to 15 months for a typical newspaper printing plant,” he says.

Hence, according to Pandya, a printer can get more benefits at reasonable investment by retrofitting the QI Press Controls solutions than installing new press. “With joint expertise of our sister company EAE Controls, we provide our consultancy and support for such upgradation of press for automation,” he adds.

See All

See All