NPES Print Business Conference 2013 Day one - session two

The technical sessions on day one of NPES Print Business Outlook Conference 2013 touched upon a series of topics.

25 Feb 2013 | By Supreeth Sudhakaran

The post lunch technical sessions began with a joint presentation by Rajeev Warrier, vice president of research and development, Electronics for Imaging and by Baiju Gujarathi, senior vice president, IT and governance, Repro India.

Warrier spoke about trends that need to be watched out for and followed. He said that with web-to-print emerging as a business opportunity across markets, rather than treating it as mutually exclusive technologies, more and more businesses are opting for a convergence of conventional and web-to-print solutions. “The whole approach to automation in print industry should be different from a standard approach. Planning and scheduling each job is getting more important day-by-day,” he said, adding, “All this will substatialise only if you keep your data properly managed. Don’t expect an installed software to work wonders. Perfection takes time.”

Gujarathi shared his experience from working with Repro in terms of how the company has been able to maintain an edge in the times when there are threats from the online web-to-print businesses.

“Repro has doubled their income in the last four years because of internal operational efficiency. Automation helped us achieve internal operational efficiencies,” he said. Asked about the time taken to attain ROI, he said, "ROI should be seen from two fronts: tangible and intangible. The finance is the tangible factor in ROI, and it took us around 18 months to achieve ROI. The intangible aspect is that our back-end process and the production have improved several folds. Scalability has improved; and that is the only way to achieve growth nowadays.”

The session was followed with a presentation by Hal Hinderliter, principal, Hal Hinderliter Consulting Service titled making print alive. The session was earlier assigned to William Kip Smythe, NPES vice president, global programs, NPES. However, due to health reasons, Smythe couldn’t travel to India.

Hinderliter touched upon various innovative uses of print that are currently in active use. He began his presentation by saying, “Now print smells and tastes good too.” He was referring to the scented and edible inks being used in the packaging that adds the sense of smell and taste for enticing the consumer when placed on the supermart shelves. He also briefly explained RFID, QR codes, clickable paper and many more.

“Augmented reality makes print interesting and last longer. As long as print can be rightfully positioned as the most effective form of marketing, a case can be made that printing should control the delivery of all marketing services. Using personalised URL (PURL) gets in more responses. It is the time to stop printing and start supplying marketing services that can best support your client needs,” he said, ending his presentation.

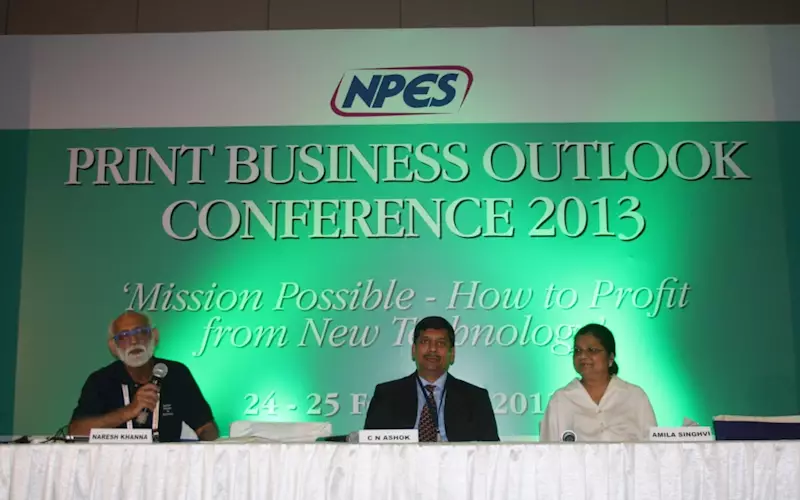

The third session post lunch was chaired by Naresh Khanna, publisher, Indian Printer and Publisher and the panel consisted of Amila Singhvi, managing director, International Print O Pack and CN Ashok, director – commercial, Autoprint Machinery Manufacturers. The panellists deliberated on various ideas and initiatives for organisational success.

“We made two important decisions: investment in CRM and ERP. These investments cost us around Rs 2.5-cr and it was completely IT, but now we have over 9,000 installations. Because of implementing the ERP, the financial details of the company are available by the third day of the month, stock details are accurate to the extent of 90%, and the cost of inventory management has gone down,” said CN Ashok.

Elaborating Autoprint’s success mantra, he said “Products should have the features of a blue ocean. Identify the needs, develop products and give it to the market. For example, manual die-punching was the most accident prone area in printing factories, so we built an automatic die-punching machine that was affordable for smaller companies too.” Blue Ocean Strategy is a business strategy book first published in 2005 and written by W Chan Kim and Renée Mauborgne of The Blue Ocean Strategy Institute at INSEAD. Blue Ocean strategy suggests that an organisation should create a new demand in an uncontested market space rather than compete head-to-head with other suppliers in an existing industry.

Calling book packaging as a sunrise segment while maintaining that book printing too holds promise, Amila Singhvi said, “We forayed into packaging because it was the sunrise industry, and it is still the sunrise industry. Commercial was the bread and butter so we couldn’t shelf that out. We slowly ended commercial printing units because it was largely fragmented and unorganised; and now we do only book printing for exports to European markets and domestic market.

Quoting statistics from a recent report by KPMG, Singhvi said, “There is a growth of 73% in text book printing in the last five years in India. The demands of books has not gone down. The future holds promise for printed books, while the volume of magazine printing has fallen down. Developing countries hold a lot of potential. Africa for example, has a dearth of good textbooks. So till 2025, we believe books are going to last.”

The technical sessions of the day ended with a second presentation by Hinderliter in which he talked in brief over hot technology trends in the printing industry. He said, “Digital print isn’t only CYMK, value added differentiation such as contour cutting and 3D spot coating to anti-counterfeiting and metallic colours has become an epochal factor for gaining an edge in the market. More throughputs, not only with larger sheet size or bigger machine but also with lesser changeover times and servo controls, is finding place in the minds of consumers before investing in capital machinery. Higher quality is now being superseded by the new trend of reducing setup, waste and spoilage.”

While the day one had more thrust on topics which broadly discussed the various trends and best practices in the industry, the second day of the show (24 February) will entail a number of sessions for newspaper and packaging printers and begins at 11 am.

See All

See All