Inkjet caused ripples at the last Drupa but very little has transpired in terms of a commercial roll-out. However, more than 48 inkjet presses were on view during Labelexpo. This sets the game for inkjet. And it is my view that at Drupa 2016, it would be interesting to see the digital tussle in the sheetfed inkjet space.

Sheetfed B1 and B2 inkjet is in its early stages, where promise is carrying more weight than reality, but in concept at least, there is no doubt that they will be compelling, it all depends on whether the developers can deliver, if they can it may mark the beginning of the end for offset litho’s 50 year reign as Badshah of the print world.

The quick snapshot of who I believe are the front-runners:

While Fujifilm already has J Press 700 and Screen has Truepress JetSX in the B2 sheetfed inkjet space. And since Drupa 2012, the others are not far behind.

Fujifilm J Press 700

Both Heidelberg and Fujifilm are set to launch B1 inkjet presses, and Konica Minolta and Komori will launch their co-developed B2 printer.

Komori’s B2 sheetfed inkjet press the Impremia IS29 will be unveiled at the show. The Impremia IS29 came out of collaboration with Konica Minolta, which sells an almost identical machine under the KM-1 badge. Both machines use Konica Minolta printhead modules, controllers and RIPs and a Komori transport system, based on its existing litho sheetfed technology. Komori also assembles both machines.

Canon’s first cut-sheet inkjet press, Océ Varioprint i300, which was announced in 2015, will also join the inkjet party.

The first inkjet device coming from Xerox’s stable post-Impika acquisition, Rialto 900 roll-to-cut press is a rather compact machine even with sheeter at the end of the press. It’s a single pass duplex machine.

Drupa 2012 saw a prototype of Delphax Elan and MGI’s Alphajet as a concept. Both the machines are expected to be up and running at the show in May-June 2016.

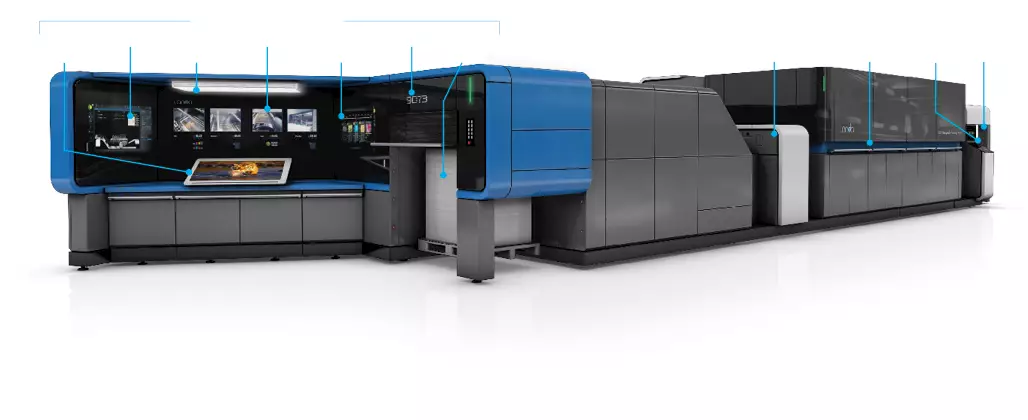

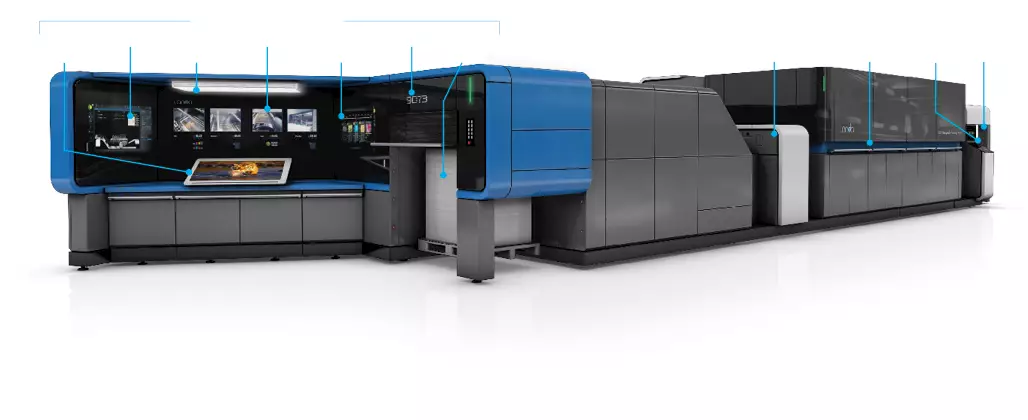

PAGEWIDE WEB PRESS T1100S

The product, which HP Inc and KBA have launched, claims to be the world’s most productive high-speed digital inkjet press, with the PageWide Web Press T1100S, and is aimed at the packaging market. The gigantic inkjet web press with a web width of 2.80m (110 inches) was developed in under two years by HP Inc and KBA-Digital & Web Solutions in close co-operation.

The HP PageWide Web Press T1100S prints at speeds up to 183m (600ft) per minute, and produces a printed area of 30,600sqm per hour, and, say its developers, will enable packaging manufacturers quickly take on new, complex jobs at speed.

Here the data speaks. So, digital printing is the fastest growing process in packaging with a projected annual growth rate of 17% and is expected to be worth USD19bn by 2019. Digital packaging solutions now also enable cost-effective short runs and unlock the ability to make every box different.

There are strong indicators that India will have its first HP T1100 by the end of 2016.

Why this buzz about inkjet?

For starts, inkjet has boosted wide-format printing. The applications which are possible on an inkjet wide-format printer are astounding.

In cut-sheet digital printing, it has transformed transactional printing.

During Drupa 2012, we saw high-speed web-fed inkjet through Kodak, HP, Fujifilm, Impika, KBA, joining Océ, Ricoh and Screen, which had launched systems four years prior to that.

Sheetfed inkjet caused ripples at the last couple of Drupas. And yet, in spite of the buzz, the installed base has not been great. Quite a few beta sites; and not more than 100 of these presses sold around the world.

During the CEIF show in Mumbai, A Appadurai spoke about how HP Indigo10000 has been the most successful of the B2 sheetfed printers with around "three" installed in India. But the 10000 is a toner press (albeit with Indigo’s liquid toner) and as such has speed restrictions (as compared to litho).

Watch before you inkjet

So what are the things to look out for when investing in inkjet?

In my view, there are three things.

- Can inkjet operate at offset litho speeds?

- Can inkjet produce offset litho quality?

- What about pre-press (since there are no plates and no makeready), does it mean a press could produce non-stop print?

So where would the new sheetfed inkjets slot into commercial digital print? Will the old concepts of maximum run lengths of 500-1,000, depending on click charges and service costs which used to see a job migrated to litho, become obsolete. One thing is clear. With inkjet, print runs will be in the thousands. One thousand books, now printed offset, could be done on an inkjet press.

Some print firms like Mail Order Solutions have identified inkjet’s potential and gone for it. Also making good money in the bargain.

So five things about inkjet that I picked up from MOS.

a) Inkjet technology continues to evolve and the inks (especially for wide-format printers) are more flexible with an increased colour gamut

b) Substrates or lack of a variety continues to be an issue. Look out at Drupa if you can print on specially treated papers or on coated stocks for matte, silk and gloss applications.

c) Decide what you want to do? Is it books alone?

Additional applications like magazine printing, catalogue printing and others are now doable on inkjet with all the benefits with regards of individualisation and customer targeted content without additional cost related to special inkjet treated papers.

d) The applications for inkjet are many. There is coding and marking, security numbering, photo-printing, wide-format, flatbed imprinting systems, narrow-web, high-speed wide web and sheetfed, to name a few. Again, identify your focus area.

e) In addition to graphics and packaging, as the recent Fespa in Europe showed us, inkjet is making rapid progress in textile printing, ceramics and industrial/architectural decoration. Then there is the new arena of 3D printing, where inkjet is an important enabler. Outside of traditional printing and graphics, inkjet has revolutionised ceramic tile printing and it is growing very strongly in textiles and other industrial decoration applications – from pens and memory sticks to architectural glass and laminated decor.

Print on inkjet

My sense is (based on available evidence), the kind of print jobs which could succeed on inkjet are:

1. Print runs from 50 to 5,000; a lot more when VDP is added.

2. 500 annual reports printed four-colour CMYK on art paper in two hours along with binding

3. Ideal for high volumes of mailers and catalogues

4. Digitally printed single sheet newspapers will see a shift from advertising as the main income to high calibre journalism. The manner in which newspapers were published hundred years ago. This means, digital delivery of news reporting on an inkjet system

5. Inkjet in the 3D printing sector. A residential house was built onsite with a 3D inkjet printing system. Plus 3D inkjet printing is being used in the medical sector particularly in the dental area.

The Nano curtain

During Pamex, I met Guy Gecht, the CEO of EFI, and this is what he said when I asked him about the Benny Landa project. "The partnership (with Landa Corporation) is fantastic. The Fiery we are building for Landa, who in turn is building an extremely fast high-quality digital press, has been very challenging. Right now I can only tell you that we have put in a very strong focused effort to build the Fiery. I am happy to share that every time Benny talks about the Fiery, he tells me how impressed he is with it. Once Benny Landa starts to shape the Nanographic digital presses, I think the end customers will be very happy with EFI and its combination."

Again, the unspoken theme is, B1 inkjet may be challenged by the nanographic technology developed by Benny Landa’s Landa Corporation.

Landa’s technology started with the NanoInk, a radical new printing method based on tiny particles, that are just a few tens of nanometers in size, claimed the showman, Benny Landa, the chairman and founder of Landa Corporation. At Drupa 2012, Landa explained that at this size the pigments develop special properties, producing a very pure colour, so less pigment is needed. The technology is claimed to be super-efficient light absorbing nano pigment, which are laminated to the stock during printing.

The water-based ink will be shipped as a concentrate in containers and then diluted to the correct working concentration inside the press using tap water, with the press system handling any necessary water treatment, said Landa.

Landa’s - range of presses include the entry-level S5, the high-end S7 for the commercial market, and the S10, a B1 (41-inch/1,050mm) format for commercial and folding carton production. Printing on any off-the-shelf substrate in up to eight colours, Landa claims the S10 is optimized for commercial printing, direct mail, POP/POS, boxes and sleeves, blister cards and micro-flute applications.

The W-series W10 is aimed at short-run flexible packaging segment while the W-is a label printing segment.

Landa has claimed beta siting of its single-sided Landa S10 Nanographic press ahead of Drupa 2015, but it remains to be seen if it can overcome the coated stock jitters.

Coming back to sheetfed inkjet, we have started to see sheetfed inkjet presses (the three Delphax Elan installed at £420,000, which is reportedly half the price of rival sheetfed inkjet presses; Canon with the Oce Vario Print i300, Xerox the A4 Rialto 900, and Fujifilm’s second generation JetPress 720S, will we see the sheetfed inkjet breakout of the top end toner press league?

The speeds of the sheetfed inkjets shown at Drupa 2012 were nothing to write home about, but the developments since have been promising. And if it can continue to raise the bar at Drupa 2016, it could well end up challenging the dominance of offset and the imminent Landa phenomena to become the preferred technology.

For that we shall have to wait till Drupa 2016.

Conclusion

A whole paradigm shift will transpire at Drupa 2016.

And inkjet will play a big role in it.

We spoke to a publisher at the recent Delhi Book fair who produced a children's bedtime story books, full colour both sides plus cover, in an unusual size (225x157mm). It was designed to fit into an international airmail envelope. It was inkjet printed on demand with the option of a personalised cover.

The inkjet component was flawless and very easy.

From this, I can gauge that inkjet technology will impact book printing. For this, it could disrupt the traditional publishers' business model, and its' relationship with the printed book.

Also, it will de-skill the print industry. Already, we can see less and less of pre-press prowess which was a must because one had to deal with film and plates.

An interesting comment I picked up on an international forum was about how "each and every single page of a book being printed with variable data, there are no signatures to collate. Finished book blocks are delivered at the end of the printing process."

So do your studies and surveys on inkjet because it is going to be better, faster, cheaper and a mainstream technology. Pull out your calculators and see if it is less expensive, too.

Happy window shopping!

PrintWeek India is a cooperating media partner at Drupa 2016

During the CEIF show in Mumbai, A Appadurai spoke about how HP Indigo10000 has been the most successful of the B2 sheetfed printers with around "three" installed in India. But the 10000 is a toner press (albeit with Indigo’s liquid toner) and as such has speed restrictions (as compared to litho).

During the CEIF show in Mumbai, A Appadurai spoke about how HP Indigo10000 has been the most successful of the B2 sheetfed printers with around "three" installed in India. But the 10000 is a toner press (albeit with Indigo’s liquid toner) and as such has speed restrictions (as compared to litho).

See All

See All