Mehul Desai says the recent investments are a key to his firm’s continued success and ensure MOS grows from Rs 120-crore to Rs 300-crore in the next five years.

Ramu Ramanathan (RR): After a brief lull, MOS seems to be busy. So, what is happening at MOS?

Mehul Desai (MD): There was never a lull. We were working and building our capabilities. In 2013, we decided to double our capacity. We were running three shifts and were full up. Also, we were looking to introduce new technology to improve our workflow and turnaround time. Since we were expanding our client base and client profile.

RR: Let’s talk about the investment in Ricoh Infoprint.

MD: It was necessary. Volumes were going up, clients were asking for more stringent turnaround time, and flexibility was needed. As I said, we were already at full capacity. The answer to all this was inkjet.

RR: A lot of people are migrating to inkjet. Is it the future?

MD: I would like to believe so. A lot of money is being spent by manufacturers on R&D for inkjet. I have seen the technology evolve over the last 10 years; Better print quality, faster machines, lower cost, etc. On the other hand, we do not see this on toner-based machines. I do believe that inkjet will dominate in the near future if it is already not doing so.

RR: Manufacturers are offering cut-sheet inkjet options for those who do not want to opt for a continuous feed. An interesting phase?

MD: Absolutely. We will see installations of this type going up, both in monochrome and colour. The per print cost is going to be much lower as compared to a laser click. The market dynamics will force this change. I am already seeing a lot exciting options on this.

RR: The other big tickets at MOS are the CMC and the Hunkeler.

MD: Our work at MOS is very complex. We have multiple personalised elements in one mail pack along with barcodes, etc. Hence it was necessary for us to have a machine which was capable of collating and inserting variable elements without errors. It took us a long time to identify the right supplier for this. And finally, we decided to go with CMC and provided all the information we had. Creed Engineers was also a part of the process and they were all very supportive. It was a long drawn process which involved a lot of research, studying our work, and understanding current as well as future needs. We were going to invest in an inkjet along with an offline slitter from Hunkeler. The output from the inkjet would be huge, but if our collating and folding was going to be manual we would still have a problem. Hence the automation was needed. At the same time, we did not want to give up on the manual part as it allowed us flexibility. Odd-sizes jobs which we have would still need the manual collation and folding. Hence we have opted for a combination of both.

RR: What is the plus of an automated envelope system?

MD: With our manual collation and folding process, we were able to produce 1,50,000 mail packs every day. This means having a large number of people, which requires space. We could not have more people as to manage them and create space was an issue. With the CMC machine, we can produce another additional 150,000 plus the earlier 150,000 from the manual process. Hence, our post-press capacity per day would be 300,000 mail packs. The 150,000 from CMC requires a team of four only per shift. So the automated system gives us efficiency, speed, and lower cost, whilst our earlier way gives us flexibility. Best of both worlds.

RR: Did you evaluate a lot of players in the market before you selected Ricoh InfoPrint 5000?

MD: For inkjet, we evaluated the big players in the market and found that Ricoh was the best option for us.

RR: Have you been able to shift a lot of your existing business to the Ricoh?

MD: Yes, with clients demanding faster turnaround times, now we are able to deliver to them. Once the artwork is in, our form set-up and pre-press get it ready for the inkjet. It’s a complete production line, where the roll goes in, the printing is done (including the VDP), and then it goes to the slitter that makes the sets. Then, depending on what the planners have decided, it goes on the CMC or for a manual operation. As a result, what used to take us three days can now be completed in a single 12-hour shift. A lot of existing work has been shifted to the inkjet press. This has freed up the offset machines and the digital cut-sheet machines. Now, we are able to accept more work and reach out to newer clients.

RR: What about a punching system?

MD: We looked at Autoprint. The company and this equipment were recommended by Nitin Shah of Award Packaging. Autoprint has a fantastic machine which has proved to be a real workhorse. In terms of investment, it was a small investment as compared to the CMC and Ricoh Infoprint, but the output and efficiency have been supreme.

RR: This is a question on behalf of the Rs 10-crore player. How does a print firm raise Rs 20-25 crore?

MD: The investment decision is based on the quantum of work and projects that we have. We also consider the prospects or the future opportunities, which is more like a work in progress. Based on this, we make a projection, evaluate it, and submit the project to our bankers.

RR: Is it tough to raise money?

MD: It is tough. More so when you are a start-up or new. In the initial years, we funded everything ourselves. My sister Dharti and I put in all that we had saved or could borrow in our personal capacity, since Banks were not willing to lend to a new company. Only in 2009, after nearly seven years of being in business and having achieved some size, we were able to get our bankers to finance our Malad unit. For us it was a big move. We got a term loan for seven years but we repaid in four years. This happened because we were able to aggressively chase business and win projects and also due to prudent and austere measures adopted by our team.

RR: So you got your second loan because of your track record?

MD: Yes to a great extent. For this round of investment, we also utilised buyer’s credit instead of just a term loan. This helps bring down the interest cost. Since the banks do not provide 100% of the requirement the rest has to come from the company’s reserves.

RR: When we had a chat, five years ago, you had 15 customers. Today that number has gone up.

MD: Yes, the number has gone up significantly but so has the team strength at MOS. What has not changed is that we still remain customer-centric. Our investment strategy and our sales and marketing strategy are all driven by what our customer needs and in the direction in which our customer is moving.

RR: What is your daily brief to your team?

MD: As I mentioned, our focus is our client. The brief is simple: do whatever it takes to make the client see the value of working with MOS. Look at the bigger picture and take decisions based on long-term vision rather than short-term gains.

RR: What are the error rates in your business?

MD: Error rates are very low. We are lucky as a lot of our people have been with us for a long time. But if I had put a number to it, I would say that we are 99.3 percent accurate. This comes from having strong SOPs, adhering to them, and improving on them. Prithvi and the team have put in a lot of hours and efforts to develop these SOPs.

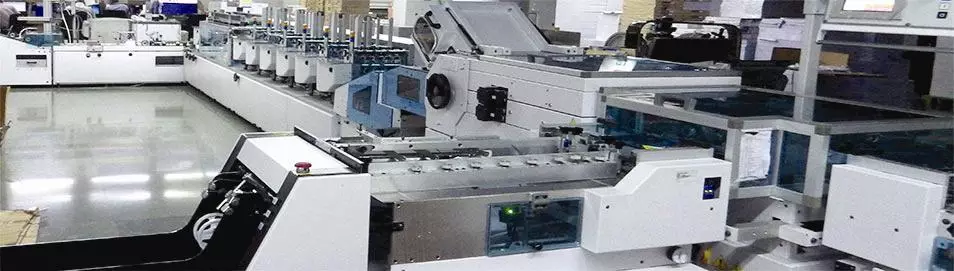

MOS' Shopfloor

PRE-PRESS EQUIPMENT

Kodak T 860/ T 1250

Kodak Trendsetter 400 III Quantum platesetter

OFFSET PRINTING EQUIPMENT

SM 74 Heidelbergs - four-colour with 53 x 74 cm with high-pile delivery (two)

SM 74 Heidelberg - two colour with 53 x 74 cm with standard-pile delivery

DIGITAL PRINTING EQUIPMENT

InfoPrint 5000 (general production colour)

Xerox Nuvera 314 (monochrome)

Xerox Nuvera 288 (monochrome) - four

Xerox Nuvera 144 (monochrome)

Xerox 4112 (monochrome)

Oce VarioPrint 6320 (monochrome)

Canon ImagePRESS 1135 (monochrome)

HP 9050 DN Laser Machine - five

Xerox iGen4 Press – four-colour

Xerox C75 colour press machine

POST-PRESS EQUIPMENT

CMC 400 – envelop inserting kit

Punching machines - three

Polar 115 XC – automated high speed cutting machine - two

Lamination machines - two

Window pasting machines - two

Stahlfolder KHC 78 – Flat pile feeder folding machine

Pinning machines - two

Strip gumming machine

Welbound perfect binding (six clamp)

Kern Pagemailer 18F

Autoprint punching machine

Pratham Superfold Machine - PGV PF 418/618

Redland - Automatic Window Patching Machine – CF 200

Envelope-making machine CF 400 - Three

Book binding machine

Wiro presser machine

Shrink wrapping machine

Strapping machine

|

RR: Would you now say that data is your USP and gives you an edge over the others?

MD: For sure. If you are doing VDP, you better understand data or else you will end up making mistakes. Our ability to understand this along with our focus on what the customer needs does surely give us an edge.

RR: How?

MD: For example, we have experts who understand the verticals they handle. For instance, if a person is handling the banks and financial institutes, then we have trained that person on that vertical. He or she will know the requirements and is able to anticipate and be better prepared for them. It makes a huge difference to the service level the client experiences.

RR: Who controls the data?

MD: Even when data is provided to us, it is controlled by the client. The data is sent in an encrypted form using SFTPs. Some clients insist on dedicated servers with point to point connectivity. This ensures that data is only available to those who are actually working on it. Clients are spending huge amounts of money to ensure that their data and other intellectual property is protected. They work with companies who have systems and processes to protect their data. This is why MOS went in for an ISO 27001-2005 certification. We follow these processes totally.

RR: What kind of data service is offered by MOS?

MD: Data service is part of the overall proposition from MOS to its clients. It is a value add. There are two types of services that we offer: one is the cleaning up of data, in which we quote a cost to update the existing data by means such as email, internet, or telephone calls. The second type is a basic postal hygiene check where bad or incomplete addresses are removed.

RR: How have you integrated software into your system?

MD: We take the software integration with IT as a part of the overall investment and expansion activity. We spent a huge sum on upgrading our IT infrastructure in our current expansion. The reason is that you have machines that can produce at a certain speed but if the file transfers and workflow are slow, then you are compromising your efficiency. Hence, we needed to ensure that our servers have the capacity, the internet connection is fast and able to handle the traffic, the software is capable of handling the volumes and so on. Along with the servers, we upgraded all our network switches, firewalls, and data storage devices. There is no point of having machines which are fast if it takes you time to open an art file or a data file. All this was done so that our IT works in tandem with our production line.

RR: So if you hadn’t invested, it would have been an error?

MD: It would have been a big mistake. We knew from day one that we needed to invest in IT infrastructure, both hardware and software. We have recruited a lot of young software engineers who are dynamic and are acquainted with the latest technology. This team understands the requirements and guides us on the same. They even accompany our business development teams for client meets to understand and get first-hand information on client expectations.

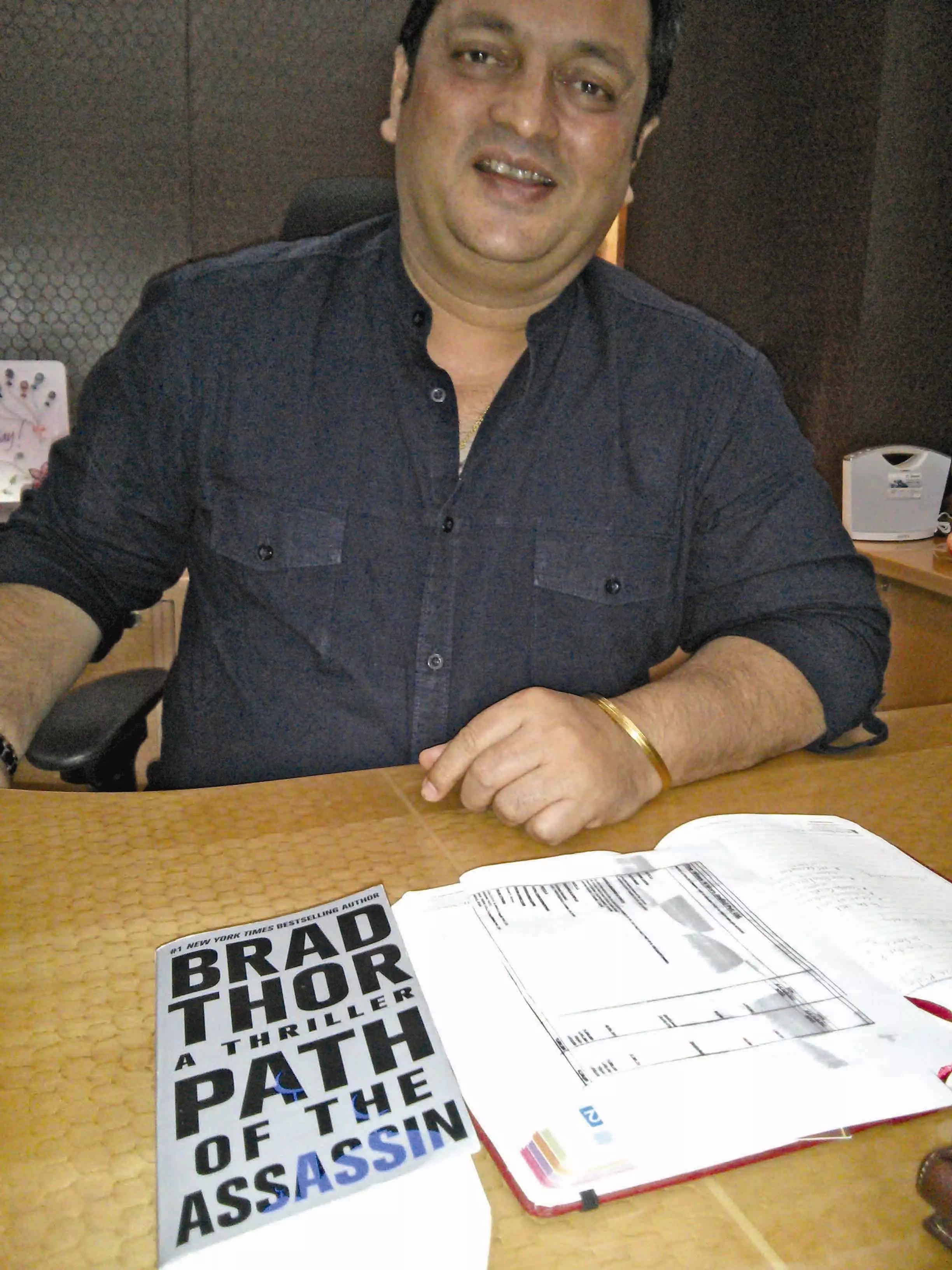

Prithviraj Desai, Director at Mail Order Solutions

|

|

You joined MOS in February of 2013. How do you see the new chapter in MOS today?

Prithviraj Desai: The new chapter at MOS is very promising for me. It is yet another growth phase. Growth is what augments overall progress, and that is what the team at MOS and I strive for.

With the recent investments at MOS, is it a re-launch with higher stakes?

PD: I agree. It is a sort of re-launch with higher stakes because it is upon me and my senior team to take us from Rs 120 crore to Rs 300 crore in the next five years. However, we are in a position to safeguard our interests.

Data holds the key. How so?

PD: We realised the importance of data in our business at an early stage from learnings from international clients. We learned about standardised address formats for different countries and how to handle data as per clients’ expectations. Consequently, we developed skills and expertise in data handling operations via training sessions with consultants and focused on data security to win our clients’ trust.

Please explain how you cope with the data juggernaut at MOS?

PD: Data is of utmost importance among our domestic clients as well. It helps to talk constantly to our clients about their business and what role data plays for them. This helps us to understand their needs better and anticipate future requirements.

You have invested a lot of time and energy in the SOPs at MOS. How did you arrive at it?

PD: Trial and error. We started documenting which processes worked and which ones didn’t. We learnt from the errors by using them as reference points. We then made SOPs containing processes that worked most efficiently.

How painstaking is it to maintain it?

PD: At the initial stage, the only thing a newbie has to do is follow the SOP. Soon enough, it becomes a habit for them. The SOPs are set in such a way that there are checkpoints within them to maintain process integrity.

India has more people going online with a mobile device; and millions of users on Facebook. Under such circumstances, as a young print entrepreneur what is the future of print?

PD: I believe the future of print is quite promising. However, targeted multimedia communication is the key in this day and age. Print coupled with other media such as mobile communication, emails, and social media has a tremendous potential. Innovation is the key to combining all of these media together.

Describe a typical day at MOS

PD: I get into the office at 9 and immediately scan through my emails and reply to necessary ones, after which I review my to-dos for the day. This is followed by a short breakfast in the office with some of my team members. Then I proceed for my daily rounds throughout the press. This involves meeting with the staff on a one-on-one basis, discussing jobs, and surveying operations. This takes between 30 to 90 minutes, depending on whether or not I have meetings scheduled in the first half of the day. This is followed by lunch with my team. Post-lunch, I spend 90 minutes on my emails and my to-dos. I meet my senior managers individually for the next few hours and review operations. Lastly, I recap the entire day’s activity and head to the press floor for my evening rounds. And thus, my day ends.

|

|

|

|

Technology view: Technology is changing rapidly. If you’re not going to embrace it, you are going to miss out. You cannot be scared; you have to evolve.

Market view: The client is evolving, becoming more demanding. Technology, too, is evolving. Opportunities will come up and big ones at that. Our Industry too will evolve and change. There will be tie-ups, mergers, consolidation, etc.

India as a print hub: I see India as the printing hub of the world. I believe it is possible. For that, we will need government support and favourable policies. I firmly believe we have the capability and a solid industry. However, our industry has the problem of over capacity. Two things are going to happen. First, small to medium size firms will be swallowed by the bigger ones. Second, inefficient firms will be left with no other option but to shut down due to mounting losses, debt burden to banks, borrowers, etc. Today, a tough Companies Act has been amended. It is also going to be difficult to raise capital. But at the end of this, the industry will emerge more efficient, healthier, and with an optimistic outlook.

The MOS brand: We believe that over the last 12 years, MOS has built a strong reputation. The team has worked very hard, without compromising in material or workmanship. Today, our clients and peers recognise us for this. We have to continue on this path as one cannot rest on past laurels. Today, people seek us out and our clients recommend us to others. As long as we let our focus be our client, we will continue to grow and become stronger and better.

|

See All

See All