Looking back in anticipation

Printing has undergone a sea-change over the last few years. While it is right to express the nostalgia over how print was, it is also important to step into the brave new world of technologies and make them work for us. Subhasis Ganguli takes a trip down the memory lane, before charting the roadmap for the future.

26 Jul 2016 | By Subhasis Ganguli

I am sure there are many like me who have been associated with print publishing, more specifically with print, for the last few decades. I consider myself lucky to be able to witness some massive changes and technological advancements. These changes have brought opportunities as well as challenges.

Wind of change

It was not very long ago that I used to work with movable types and manually operated treadle machine, though Manipal had been using printing machines with electricity since the pre-independence era, earning its name as Manipal Power Press.

In the last decade, quite a number of entrepreneurs have braved the barriers to enter into printing despite its reputation of being a conservative and family owned business, bringing with them fresh ideas and a capacity for risk-taking, unencumbered by prejudices. As a result, offset engines slowly crept in and replaced flatbed printing.

In typesetting, movable types became automated and manual composition was replaced by pneumatic hotmelt metal casting. Soon, we saw a huge change, which took industry by storm.

Phototypesetting, along with optical character recognition technology, initiated the modernisation of the typesetting process, followed by DTP. Since then, continuous improvement of the technology has continued to make typesetting easier and more user-friendly.

Very soon, typesetting could be a part of the publishing process handled by copy editors with a better interaction with the authors virtually, with the help of ‘authoring tools’.

One change leads to another

We also witnessed huge changes in the print segment. While printing machines became faster, there was the introduction of the ‘perfectors’ of different combinations, and commercial and publishing started using multicolour presses. Then there were continuous-fed heatset and coldest printing machines, which catered to big run to start with but slowly started printing moderate runs as well. The print process had started to become hybrid.

Finishing was not far behind. Though the starting was slow, it picked up speed from manual binding to single clamp and then multi-clamp binding machines. We saw semi-automatic and automatic hard case making, binding lines, and improvement and automation in folding and gathering. Now, sensors are being used in the finishing line to eliminate errors.

Entrepreneurs have started looking for automated solutions in an effort to reduce manual intervention as much as possible and to achieve accuracy, consistency and even shorter turnaround time. The latest addition in this area is PUR binding, which allows the printers to have flexible spine (without sewing). Readers could now lay the books flat while reading without being afraid of dislodging the pages from the binding. This also improved the turnaround time by mitigating the bottleneck of sewing and bringing gathering to finishing online.

Digital changed everything

The maximum change we witnessed has been in the area of pre-press. I still remember struggling to separate colours correctly (though by then scanners had made their entry to India). Before that, it was glass plates and films. Even then, images used to scan in continuous tone. There were different colour correction methods: masking, followed by the use of different type of films (positive, negative, Geva or using auto screen films for halftones and circular screen film for colour separation).

In the 1980s, our life in the studio (yes, we needed to pursue this part separately in an actual studio and not on a desktop studio the way we see today) was governed by camera, enlarger and contact frame. By this time, the world had started using Quantel engine, which could edit graphic art as well as videos. For some reason, the Indian printers never took to this capability. Doordarshan bought the first Quantel machine, which they never used. NDTV bought the second one, which they used extensively (according to a fellow industry stalwart Dipankar Banerjee of the then HTA). It was strongly felt that there existed a gap in the compatibility of scanners with the process followed to deliver the desired end-result. The industry was poised perfectly to embrace the revolutionary change we witnessed thereafter with the introduction of Mac.

Mac has changed the print world today. Initially, typesetting used to be done through Ventura, which was a robust and sustainable platform originally from Xerox. A bouquet of auxiliary software, such as PageMaker, CorelDraw, Illustrator, FreeHand, and most importantly, Photoshop, soon followed.

Life was getting easier. Turnaround time improved, expectations grew from customers and businesses started booming. This reached new heights with the introduction of the Creative Suite in the new millennium. Though it is possible to work on MS Windows platform today, the preferred platform remains Mac.

Slowly, films (negative and positive) became obsolete and were replaced by computer to plate (CTP). This gave more control over print quality, longer run of plates, saving of storage space and most importantly, improved the efficiency with better control over files and increased version control.

These digital developments flagged off the current era, where everything we talk, think and deliver is digital – be it files to press from the clients (no more CRC and taping the corrections), handling the files throughout the process in press or imposing/ exposing the plates through computers, everything is digital.

Need for a workflow

This brings us to the need to have a workflow in place. I had never given much thought to workflows, until I heard Thomas Friedman’s lecture and read his bestseller The World is Flat. Until then I, like many of my peers, used to think of workflows as an unnecessary and flashy complication brought about by new-age IT companies to develop software. Our industry had survived centuries without it. However, the book and my subsequent interaction with the author was a revelation, and I was convinced. Today, all of us will agree that there is a requirement of a proper workflow in place to get the efficacy and to streamline the process. In fact, workflows are just the governance factor and the tip of the iceberg of the whole process today. With ‘critical paths’, ‘just in time demand planning’, ‘inventory control’, ‘lean processes’ and ‘supply chain management’ being used extensively to save cost, manpower and improve efficiency.

This was the time when we saw dry tonner-based digital printing slowly cementing its position to cater the demand of odd titles and then short runs. This further propagated the need for a workflow, as multiple orders need to be handled in a very short span. The technology keeps improving and we are today witnessing the evolution of inkjet digital print technology. This is faster, cheaper and could cater to the gap between dry tonner-based digital printing and litho. Inkjet could be the ideal solution for making the stock available just in time and with the right cost, control and reduce inventory, and to address short-run requirements with much more efficiency.

The time has come to have a close look to this technology and to embrace it.

Publishing at a crossroad

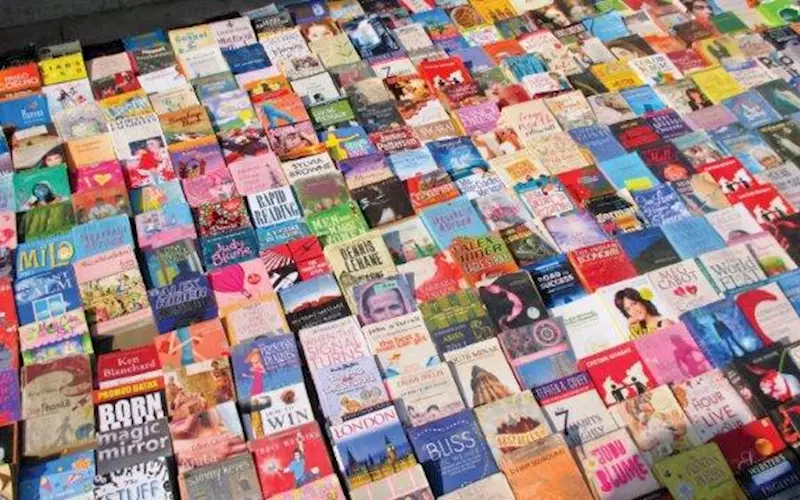

Today, publishing stands at a crossroad. On one hand, digital delivery in form of free flow eBooks, uPdf, interactive eBooks, fixed layout ePubs are on demand. On the other hand, the print runs of regular publication are coming down steadily. There are many titles published every year (though there is no data to assess the correct number), yet bestsellers are few. Storage spaces are expensive and at a premium, demands are erratic, and there are pressures to improve cash flow, decrease the recovery period and to reduce wastage. The industry is being squeezed by rising costs at the production level and an increased buying power of eCommerce companies, who demand discounts that traditional retailers and distributors could only dream of.

While the world flirts with the concept of eBooks and eReaders, the India market still is reluctant to embrace it completely, but the threat remains to the physical formats. This is not even taking into consideration our lax IPR laws, our ignorance towards the cost to environment through our paper and inks, very little knowledge about copyright laws (including fonts) and a happy-go-lucky attitude of ‘chalta hai’.

The road ahead

So, what do we need to do to mitigate the challenges and to cope with the changes? First, let us all acknowledge the change, which is the only constant today. Everything else is variable. How can we understand the expectation of the print buyers in publishing houses?

I have worked on both sides of the fence and I know that the grass is ‘not greener’ on the other side.

Do your homework

All publishers are different. Though the core activity is same – publishing, each one follows a different workflow, process and systems. It also varies from person to person, as very few publishers in India are completely system-driven. There will be manual intervention and interpretation, resulting in a difference in approach. So it is vital to understand the requirements of the publishers first. If I may draw a high-level checklist of what print buyers in a publishing house expect from their suppliers, assuming the price has been agreed upon, the top five could be:

• Positive and professional approach towards the job

• Accurate and proactive feedback in time

• Deliver what you commit

• Understanding and knowledge of the job

• Innovation to address the cost escalation and inflation

It is important to have a clear understanding of pricing in its entirety (not just the final transfer price), which could be acceptable to the publishers and could be a win-win situation for both printers and publishers.

Understand the ‘values’

There is a proverb in Bengali that you need to prepare the wicks before you light the lamp. Similarly, it is important for the printers to understand the expectations, and terms and condition of the deal before they place their offer to the publishers. I have seen many gaps in this area. Either, enough importance has not been given to this task or this task is completely ignored. In most of the cases, the price offer is driven by the workload, with the printer at that particular period, payment terms and track record of the publishers and what others are offering (especially in case of eBidding).

In the process, there are possibilities to go overboard and end up with some order that does not make much economic sense. As a result, these jobs lose priority at the time of production and get less attention, which leads to below par quality and delivery delays. This makes the publishers unhappy. This is a chain reaction, the seeds of which were sown long before the actual execution of job.

Cost is king, but price isn’t everything

Due to pressure of cost and time on the print buyers, sometimes they do not probe into the offering in details and prefer to go with L1. This practice is unprecedented in international scenario. We need to travel a long way (both print buyers and the printers) to overcome from this unhealthy situation and to make a healthy practice of costing. The printers need to understand and be careful about the fine prints of the RFP and act positively towards the same. While it makes absolute financial sense to pick the least possible costing option in a basket, print buyers need to make a prudent choice about the possible economic implications in the long-term. The onus rests not only on the vendor, but also on the buyer to be aware of the possible range that a particular job can cost (raw materials and conversion included). A suspiciously low price should ideally not exist, but if it does, should beg the question of how it was achieved to promote and propagate a healthy practice.

Realistic delivery schedules

It is important for the printers to understand the requirement of the publishers to some extent. When a delivery schedule is agreed upon between the publisher and the printers, the coordinator/ print buyer of the publishing house commit availability of stock to sales, warehouse, marketing, editorial, and so on. In turn, the commitment goes to the author, distributors, media, and so on. All plans are finalised keeping in mind the date committed by the printer. With the increasing pressure of cash flow, publishers do not have the luxury to bring the stock well in advance and then start planning to sell the book.

Hence, delivery closer the required date, and in some cases trying to achieve ‘just in time’ are targeted.

Now, if the printer fails to meet the delivery date, it would be an embarrassing situation for the publisher, who may lose the author permanently, lose potential sales and bad media coverage. It is also important for the publisher/ print buyers to be realistic with the delivery schedule. They should be well aware about the process and time requires in each stage.

Print buyers also ideally should be able to provide his/her procurement plan well in advance with the printer. This will enable the printer to procure raw material in time, plan their inventory and to maintain a better delivery schedule without any fail. This could be a win- win situation for both.

A lot of work needs to be done to get this near right. From my experience, I could say that it is possible to a great extent. This needs support from top management of the publishing house and a lot of homework. This is essential. Without a clear understanding of ‘cycle time’, number of SKU and MOQ, it is not possible to make a near accurate forecast (no forecast could be accurate in the current market condition). This could help to reduce ‘fire fighting’ on daily basis.

So, how to do it right? The answer may be a simple four-step plan:

• Do your homework properly and in advance, so there could be no gap in understanding

• Value the relationship: It takes a long time to establish and maintain a relationship. This could be the second most important factor for the business continuity

• Though cost is king, yet, price is not everything: Please try to create a value proposition for the work. Value-added proposition could stand out and could make a difference

• Realistic delivery schedules: Though the delivery should be agreed mutually, yet please be realistic with committed delivery schedule and stick to it

The most important factor of all of these lies with the print buyers. They need to understand how to supply the accurate brief and to understand the value proposition on receipt of the same from the printers. Hence, the importance of understanding and proactive communication is increasing. The printers should not feel shy to ask for clarification and the print buyers should be equipped with technical and commercial details (by doing adequate homework at their end) to answer these queries. Only then we could end up with a professional and healthy relationship that could ends with a win-win situation.

Changing printer-publisher relationship

The dynamics of relationship in the print industry has been of vendor-buyer in nature. But things are no longer that simple. Advancements in printing technology in a globalised world means that a customer is no longer bound by geography. The evolution of new formats and fickle reading habits has been pampered by choices offered by an eCommerce industry in full bloom. In this scenario, the players of the print industry need to go beyond the tested and tried ‘safe’ options. The industry needs to evaluate their long-term goals.

It is imperative for the stakeholders on both sides of the relationship to look beyond their own short-term benefits and build an ecosystem to survive the threats at various levels of their value chain by technology and processes far beyond their own.

I am around 60 years now. I have spent the majority of my life working with multinational publishers all over this country and a few abroad, and I strongly believe that this is a great industry. With proactive professional approach and positive mindset, we could set the ball rolling in the right direction, which could be beneficial for all of us.

(Subhasis Ganguli is a well-known figure around most print and publishing institutions in India and a few abroad. His family owned a printing business from 1971-1980 before he went to work with Graphitech India from 1985-1987. Since then, he has been associated with some of the biggest names in the educational and trade businesses with Oxford University Press (1987-2001), Penguin Books India (2001-2009), Pearson India (2009-2013) and one year of the Penguin Random House merger before announcing his early retirement in 2014. Since then he has offered his expertise to various firms in the capacity of an independent consultant, including but not limited to HarperCollins Publishers, among others.)

Subhasis Ganguli’s Top Eight

|

Trade publishers Harper Collins Publishers India’s second biggest publishing brand Hachette India’s second biggest, or a close third publishing brand Westland The most popular trade publisher with mass market Rupa/ Aleph The most popular trade publisher with mass market Popular Prakashan Majorly known for their publication of cook books aka Sanjeev Kapoor (Also, watch out for Speaking Tiger, Juggernaut, Permanent Black, Neeta Mehta Publication, Vishabharati, and Sahitya Akademi) |

|

Education publishers Oxford University Press Biggest dictionary publisher in India, with a good reach McGraw-Hill You cannot avoid them in higher education Elsevier Science You cannot avoid them in science and medicine Pearson Though their focus has shifted from print to service, still they Sage Publication |

|

Indian publishers Matrubhumi Wide circulation of their yearbook, especially in South India Ananda Bazar Patrika Biggest Bengali publisher in the country S Chand Big and growing with tremendous pace in education Navneet May be largest publisher in the education segment, including its stationery business MBD One of the biggest among Indian educational book publishers Westland The most popular trade publisher with mass market Amar Chitra Katha Fantastic range of content, especially on Indian history and mythology; yet to be explored to its full capability of gold mine of content they possess. |

|

See All

See All