Labelexpo Europe 2017 | Top 10 converting systems

Labelexpo Europe 2017 is slated for 25-28 September 2017 at Brussels, Belgium.

PrintWeek India and WhatPackaging? team lists the top 10 converting systems at Labelexpo

23 Sep 2017 | By WhatPackaging? Team

Digicon Series 3

AB Graphic | Hall 6, Stall A37

The flat screen printing is traditional the slowest module on a finishing machine, but AB Graphics’s has significantly increased the running speed on its new flat screen printing unit shown on the Digicon Series 3. The new module has full rotary motion while still using a flatbed screen. The physical size of the module has been reduced by over 20%, while the repeat area has increased to 410mm in the web direction, making it compatible with the Big Foot 50 hot foil stamping unit.

MBS splicer and LRD transfer rewinder

Martin Automatic

Martin Automatic will debut a new splicer and rewinder. The LRD, seen for the first time, is a two-spindle transfer rewind that winds, changes and automatically offloads rolls, without any need for carts or additional roll handling equipment. The LRD rewinder accommodates 800mm diameter rolls in the standard model while the Martin’s flagship MBS splicer at Labelexpo will feature Martin’s laser assist tape alignment system for easy splice preparation.

Futura open-platform technology

Prati

Prati will show its new Futura open-platform technology, which offers unlimited upgrade possibilities for its finishing equipment. This retrofitting can be done in-situ, is an easier process, where the machines would need to be shipped back to Prati.

Rhino II and Swift

Pantec

Pantec's Rhino II is the flatbed foil embossing, inline and offline. See new features on the Rhino II that will enhance productivity and reduce setup time. Swift offers inline label decoration making registration of patches easy and efficient.

Electro Optic Gold Line Special

Rotometrics/Electro Optic | Hall 4/7, Stall B45/D47

The newly merged companies, exhibiting in separate booths. The Gold Line is a premium die exemplifying perfect cutting ability with no liner strike on ultra-thin liners. On RotoMetrics stand (4/B45)see the AccuBase XT Magnetic Cylinders and Anvils.

DT 340 machine

Rotocontrol | Hall 7, Stall D42

The converter of digitally printed labels gets a new register-controlled lamination unit and a turret rewind-er for non-stop production. Other new machine is the RotoCut fully automatic slitting system. Check out the BL 440 for high-speed production of booklet labels.

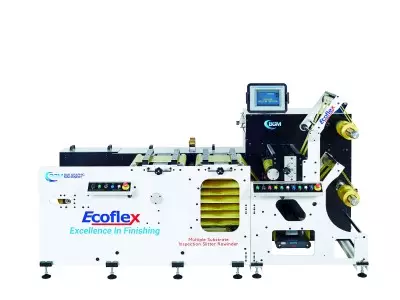

BGM Elite 450 Ecoflex

Bar Graphic Machinery | Hall 7, Stall D51

Elite 450 Ecoflex is one of the five Bar launches. It’s a full servo multi-substrate inspection slitter rewinder for unsupported and supported materials from 11 micron upwards. It’s intelligent tension control system, is fitted with a 1m-wide capacity unwind system.

Enprom eSDC

Enprom | Hall 11, Stall B28

eSDC allows several unwinder and rewinder configurations as well as integration into the central body, including: rotary and semi-rotary die-cutting processes; 100% inspection; inkjet marking; laser cutting; label insertion; and RFID placement.

Solitaire duplex slitter rewinder

Ashe | Hall 4, Stall B51

Ashe shows the Solitaire narrow web multi-substrate duplex slitter rewinder for the first time. Capable of handling 38 micron unsupported film, it can run up speeds of up to 500m/min with full rewind shaft supports during material slitting.

Flexor xCut

Emis | Hall 7, Stall D38

Emis calls this debut making Flexor xCut a ‘one-stop label shop’ because it allows companies to enter the world of label printing with ‘an affordable machine and little knowledge’. It is a 250mm wide semi-rotary machine which can work in-line with any Memjet kit.

See All

See All