Bizongo, a B2B marketplace with packaging, among other things, hopes to interact with group of buyers and sellers. Bizongo will be launching a mobile application for suppliers, which according to Bizongo, will help manage inventory, prices, inquiries, orders and live chat, as well.

Bizongo will display and make live demonstration of its sample products at the show. “Indiapack provides us a great opportunity to look at look at emerging trends and keep ourselves updated on the industry,” said Aniket Deb of Bizongo.

Deb added, “With business done traditionally, you reach out to one client at a time. If a printer/packaging company gets on board Bizongo to sell their products online, they get to project their brand to a world of potential buyers. For a print buyer, it is a large variety of options at their disposal, thanks to the digital cataloguing of all the products.”

Deb said, the annual growth rate of this sector is about 15% per annum and it is expected that annual turnover of Indian packaging industry will touch $32 billion by 2025. “This is a heartening thing,” he added.

A catalogue show for Bonvario

Bonvario Eurodrives, a supplier of industrial automation products, will showcase a raft of industrial worm and inline gearbox and motors at the show. The key highlight of their display will be the single phase motors and inline gearboxes.

Samir Wadhvan, India marketing head, Bonvario Eurodrives will be interacting with visitors at their stall. Bonvario Eurodrives has opted for a catalogue show with its bouquet of products and services at the exhibition.

Ecobliss to highlight smart innovations

Ecobliss to highlight smart innovations

Hyderabad-based Ecobliss will present itself as ‘the smart source’ for blister and high visibility packaging solutions. It will showcase the combination of industrial design and delivery of blister and transparent packaging, as well as a range of blister packaging machines.

“Actually we are going to demonstrate how all the components of various packaging are integrated in almost any style, size or shape with a wide array of functional attributes and finishings through our smart source philosophy,” said AVPS Chakravarthi, managing director at Ecobliss.

Chakravarthi said, it was a humble beginning for Ecobliss, when it began in the later part of nineties, claiming the invention of cold blister packaging. “Through the success of cold seal packaging,

Ecobliss has become a known name in the market.”

Apart from its cold seal technology, Ecobliss expanded its expertise with many new technologies, products and services. “With many years of experience in development, design, production and logistics, Ecobliss is, today recognised to be the smart source for the entire scope of blister and high-visibility packaging,” said Chakravarthi.

Venting solutions by EG Electronics

Venting solutions by EG Electronics

At the exhibition, EG Electronics will display the venting solutions for packaging agricultural, industrial, chemical and animal health supplement products.

According to Chandra Vardana Gowda, country manager – India, EG Power Electronics, “Due to chemical contamination the containers that store chemicals or fertilisers tend to either bloat or collapse due to gas formation. Also, with IPRO, which is a national organisation providing a full spectrum of healthcare assessment and improvement services; we help packaging companies to solve their technical issues by providing cost-effective venting solutions.”

He added, “The packaging business outlook looks promising and optimistic. We see a lot of packaging customers understanding the needs of venting solutions and are ready to accept it to improve their customer satisfaction.”

Gowda, accompanied by Li Jie, global sales manager – IPRO, based in China and Jaya Seelan Ramasamy, head of Asia business development from Malaysia, would be present at the stand to interact with the customers.

Commenting on the future of packaging in India Gowda says, “Opportunities galore as we see Indian economy is growing as is the packaging industry. The packaging companies in India have started to realise that by improving the standard of packaging with a little extra cost will help them to achieve complete customer satisfaction which eventually is the key for any business to be successful.”

Impakt to highlight paper pallets

Impakt packaging will showcase its range of product, which include different boards, paper pallets, slip sheet, paper core and inks at the show.

Talking about the product, Sham Batham, head marketing, Impakt packaging said, “Our paper pallet is designed as per customer’s requirement. Also, the pallets are available in any sizes, and it is totally different from normal paper pallets”.

The highlight of the event he said will be “The packaging of the product, as now everyone is insisting on quality and safety in packaging.” “The Indian packaging industry is fast growing with a high growth potential. Awareness of packaging is in high demand by various industries,” added Batham.

According to Batham, packaging will be an important aspect and will be unique to individual products.

Established in 1999, Nashik-based Impakt Packaging has three manufacturing units in Nashik, Maharashtra, Rajasthan and Karnataka.

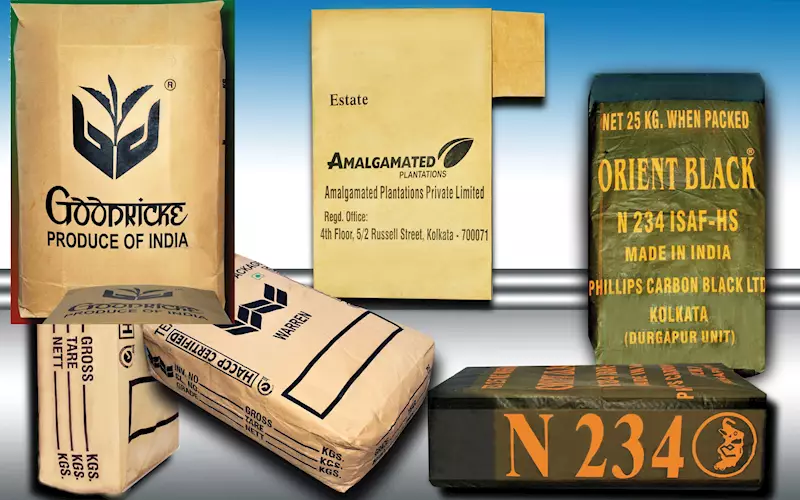

Industrial Packers’ corrugation packaging solution

Industrial Packers (IP) is set to showcase different types of heavy-duty corrugation-based packaging solutions for the industry with focus was on liquid bulk packaging.

These packaging, the company claimed, can hold more than 1,000 litres of liquid. Gaurav Dhoot, managing director at Industrial Packers, said, “The packaging can replace intermediate bulk containers (IBC) and plastic and metal container used for packaging liquid in the industry. The packaging developed can be stacked and costs lesser than IBCs.”

Dhoot believes heavy-duty packaging in industry has seen double digit growth in the last few years. “At IP, we have focused on innovation and in the last five years, we have entered into multiple packaging materials.”

Dhoot added, “Our focus is on providing total packaging solutions, to reduce product damages and optimise packaging cost. Buyers today are looking for one-stop-source of total packaging solutions. Hence, the focus is on new product development, which will not only improve margins but also stress on improving operational efficiency and control capital expenditures.”

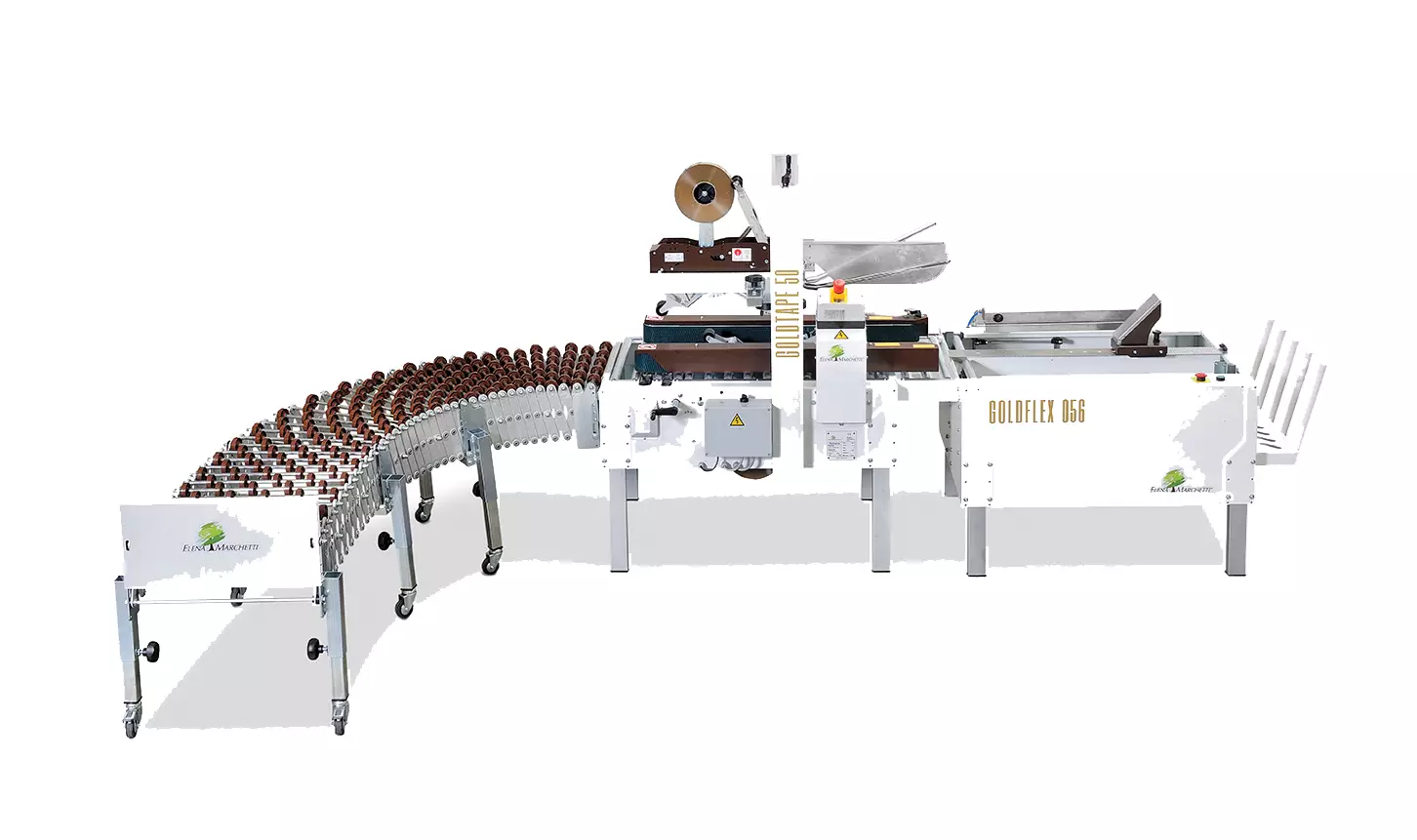

Saurashtra Systopack’s new end-of-line kit

Saurashtra Systopack newest development for end-of-line packaging like semi-automatic carton erectors and carton sealers equipped with batch coding will be the star products at its stand. The company will also showcase a variety of testing equipment for quality control and packaging materials and packaging.

According to Akshay Gandhi, director at Saurashtra Systopack, the development in packaging technology keeping the logistical needs of rapidly evolving supply chain needs in mind.

“The need for innovation is bigger than ever,” he said, adding that a passive approach will push one back in growth rate and that systematic approach is the need of the hour to plan the future. “The future of packaging in India is vibrant and dynamic. It is also challenging and surging,” he said.

SMI to focus on sustainability

SMI Coated Products, one of the country’s largest label stock manufacturers, will display its wide range of label stock solutions for various label applications, with focus on sustainability. The two-decade old company has been manufacturing a wide range of self-adhesive materials using both acrylic and HM adhesive since 2000.

“Our star products are the complete range of label stock materials using filmic release liner. These materials are environmental friendly as the films are recyclable,” said Ajay Mehta, managing director at SMI.

SMI has claimed to record successful sale of over 2.7-billion running metres of self-adhesive material, across 64 countries.

TNPL to announce its entry into packaging board

As a paperboard manufacturer, TNPL said, it is keen to update itself with the latest developments in packaging and how paperboards can play a role as a key input material in these new trends.

K George Thomas, chief general manager for marketing at TNPL, said, “We are primarily present to announce our entry into the packaging board industry by offering an exclusive range of coated boards like whitelined chipboards (WB); folding box boards; solid bleached sulphate boards, liquid packaging boards, base board for manufacture of paper cups, etc.

The company will also be showcasing, what it claims, the power of its state-of-the-art machine which is comparable with the best in the world. “We believe our products will revolutionise the packaging industry in India with the quality and tailor-made varieties that we would be able to offer meeting the best of international standards.”

Uflex to flex flexible muscle

Uflex, one of the country’s largest flexible packaging companies, will showcase it’s range of products at the show. Headquartered in Noida, Uflex is the largest fully integrated Indian flexible packaging solution provider to a range of clients across industries both in India and overseas. It enjoys a formidable market presence in more than 140 countries. Established in 1983, the company today has state-of-the-art packaging facilities at multiple locations in India with installed capacity of over 99,000 tpa.

Recently, Uflex announced that it is in the process of setting up a first of its kind Aseptic Packaging Plant for liquid packaging in Sanand, Gujarat, with a Capex of Rs 550 crores in the first phase. This project is proposed to be commissioned and operational by April 2017.

According to the company, it has been reporting consistent growth amidst increasing demand for innovative flexible packaging solutions, which is “fuelled by expanding retail industry particularly in the food segment”.

Weener Empire innovative plastic solutions

On the strength of its latest developments in the field of standard off the shelf packaging and also their capabilities in the field of rigid packaging solutions, Germany-based Weener Empire Plastics will showcase a wide range of local and global innovative standards packaging range.

Weener designs, develops and manufactures added value caps, closures, roll-on balls, jars and bottles for the personal care, food and beverage and home care markets.

Ashish Saigaonkar, general manager for marketing at Weener, felt that the state of FMCG is a concern right now and innovative ways to restrict packaging costs to a minimum, is an option. “We are a one-stop-solutions provider with a long standing reputation in the market and can help brands overcome functionality issues.”

Weener has 24 facilities in over 16 countries across the world with seven factories catering to cosmetic, food and pharmaceutical majors.

Yupo to focus on IML

The Japan-based manufacturer of synthetic papers, with representation in India, will display a range of synthetic paper, including its in-mould label (IML) papers, pressure-sensitive films and security material at the show.

The focus at the show will be the IML papers.

Yupo uses synthetic polymers to develop papers, which according to the company, are unparalleled for their combination of superior functionality and unique aesthetic appeal. According to Yupo, ILM are label substrates that give freedom of being able to create blow-moulded bottles of any design or shape. It allows users to work with recessed panels, inclines, asymmetrical features and applications like hot foil and fluorescent and metallic inks. “The colours pop, making brands visually stand out among competitors for strong shelf appeal,” said a company statement.

Ecobliss to highlight smart innovations

Ecobliss to highlight smart innovations Venting solutions by EG Electronics

Venting solutions by EG Electronics

See All

See All