A day in the life of a printer

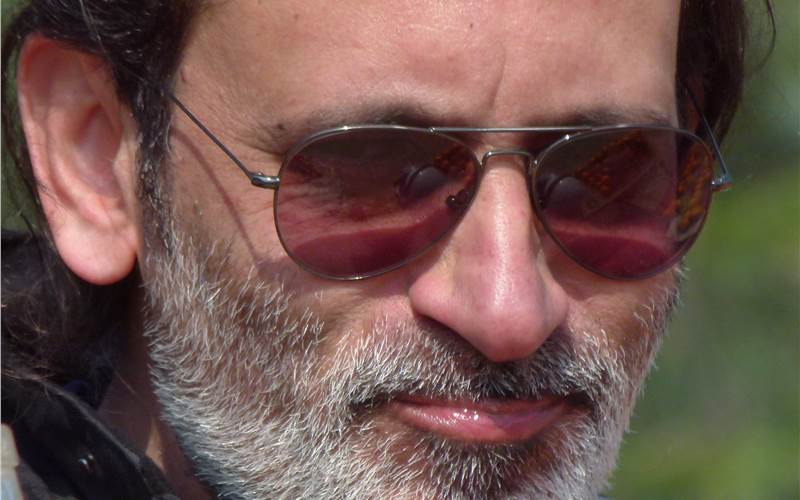

Sidharth Prakash of Impress Offset in Noida

08 Mar 2012 | By PrintWeek India

1. When you read the morning newspaper, you look for...

Besides half tones and colour reproduction, inspiring news.

2. When and how do you begin your day?

The day begins at 5am with a walk and yoga session.

3. Do you plan your day meticulously?

Daily plans are in place. However, the print industry has new challenges each day and they are taken on as they come.

4. One person with whom you would like to drive to office? Why?

Sri Sri Ravi Shankar, he manages to keep a smile under the most trying and challenging situations.

5. What's the first thing you do on entering the office?

Firstly, thank god for all I have attained and then proceed for a meeting with the supervisors.

6. How frequently do you interact with the print production supervisors? What do you commonly discuss?

The first task on the agenda is meeting the supervisors and discussing timelines and quality requirements of the jobs.

7. With the fierce competition, high cost of entry and above all, the increasing threat from other media, do you find that traditional ink-on-paper is facing a serious threat?

No. On the contrary, it seems to be increasing. The printed word can never be replaced by the chip.

8. Which is the best press in India? Why?

Pragati Offset. Their quality control seems to be the strongest and they know the intricacies and technicalities of printing.

9. How do you rate your press as compared to the leading printer's world-over?

We are way behind.

10. If you won Rs 10-crore through PLAYWIN which printing equipment would you invest in? Why?

I will invest in a Komori Lithrone. It has a great productivity and quality for commercial jobs.

11. Today we hear of innumerable printing presses closing down or being on the verge of closing down. What do you regard as the reason for this? What does this portend for the future of the industry?

The time for small and medium printers is going to be over soon. Only the large print firms will survive this change unless huge investments are made in terms of not just printing, but finishing as well, along with skilled manpower.

12. The best breakthrough in print technology in the past hundred years?

The digital print technology.

13. Most printers, repro houses and graphics art professionals - complain about the manner in which profit margins are being squeezed. The reasons they cite for this are: unfair under-cutting; increasing presence of canvassers; etc. Are you encountering these problems? If yes, then why - and how?

Yes. Profit margins are being squeezed. I feel this is because the larger print houses with spare capacity have started to undertake jobs at very competitive rates to increase their capacity. This has dented the profit margins to a large extent.

14. For a working lunch if you meet Johanes Gutenberg (the father of modern printing), what would you talk to him about?

I would request him to return and innovate some more!

15. How do you motivate your sales and marketing team? Any new promotion strategy?

Interacting and sharing knowledge with each other is the key. The strategy is to keep up to the commitments.

16. The most frequently used mantra in your organization? Your corporate philosophy?

Provide quality and timely deliveries to the clients. Be partners in progress with them. They grow, we grow.

17. The craziest deadline you've come across?

Once a lady walked in the office to get an invitation card printed for a book release function to be held within a week. She came with the the book along with some photos, 160 pages (all four-colour), and a guest list. After sleepless nights, we managed to deliver ten minutes before the function.

18. Your favourite excuse to your family when you're late?

The one that I escape with everytime, that there was a breakdown in the plant.

19. Has the domination of the printing industry reached a plateau with the arrival of new competitors?

The way of doing business has changed with the advent of new competitors.

20. Please comment on the technology and machines (press / prepress / post-press / others) that you have invested in, in the past few years?

I have invested in post-press. Pre- and press can be managed easily, it's the post-press which requires more thought. We have invested in folders and trimmers to bridge the gap.

21. In India, the two most important barriers are technology and cost. What advise do you have for the printer?

Keep up with the times as far as technology is concerned and invest in manpower training at the shop floor level.

22. How do you stay in touch with technological developments? Please comment on your official view on CTP technology and digital printing.

Seminars and visits to various units is the best way to stay updated. CTP systems have made life simpler and jobs more versatile. Most of the jobs have now shifted to digital especially with variable data.

Favourite adda: The Tea Shop in Noida

Your cellphone: Blackberry phone

Favourite wheels: Bullet Enfield.

See All

See All