There are many reasons, based on complex colour science, why the appearance of a colour image is difficult to reproduce consistently on different devices. In many ways, communication in colour has problems similar to those of communication in languages. Each device is like a person, speaking own language. Even the same language has different dialects.

The result is a breakdown in communication and misinterpreted messages. What’s needed is an interpreter capable of interpreting the language as well as the dialect, to ensure that the message is properly communicated. The same holds true for colour reproduction. Actual colours produced depend on the characteristics of the particular digital camera, scanner, display monitor, and printer used, and, because these characteristics vary from one

device to another, the results obtained from the same input on different installations can vary considerably.

First problem is R, G, B and C, M, Y, K outputs are device dependent, by this is meant that different digital cameras and scanners give different R, G, B signals from the same scene or the original, different monitors produce different colours from the same RGB signals, and different printers produce different colours from the same C, M, Y, K dot sizes.

The second problem is different viewing conditions prevailing means conventional colorimetry is insufficiently sophisticated to define colours that look alike on two different types of display.

The third problem is different monitors and printers not only describe colours differently, but also differ in the gamut of colours that they reproduce.

The fourth problem is characteristics of some parts of installation may vary with time. This is particularly true of colour monitors, any chemical processing, a printing process, and raw materials used, particularly, the substrates and colorants, i. e. inks and toners.

Colour management is the term used where colour reproduction becomes repeatable and reliable following certain norms and discipline. Colour management reproduce colours the best possible way within the limits of the colour reproduction systems using device dependent colours through the effective use of device independent colour system based on human colour vision, CIE described earlier. Every transformation of colour passes through CIE, may be called an interpreter, synonymous to language translation. figure 1.

Figure 1 - CIE colour model central to all device dependent colour systems

Each device in the network is has to go through the three Cs of colour management.

1. Calibration involves establishing a fixed, repeatable condition for a device. For display monitor adjusting contrast and brightness settings, for printer deciding on substrates and inks. Thus establishing known starting conditions and some means of returning device to that state.

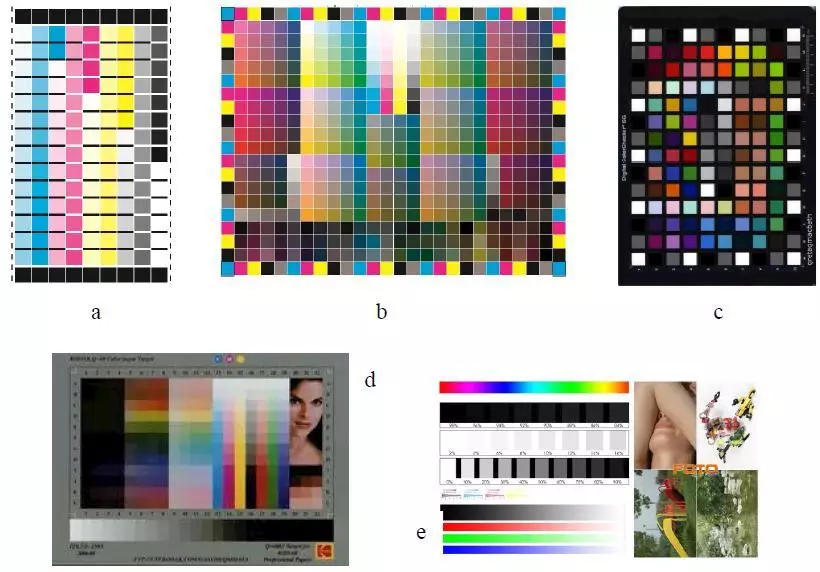

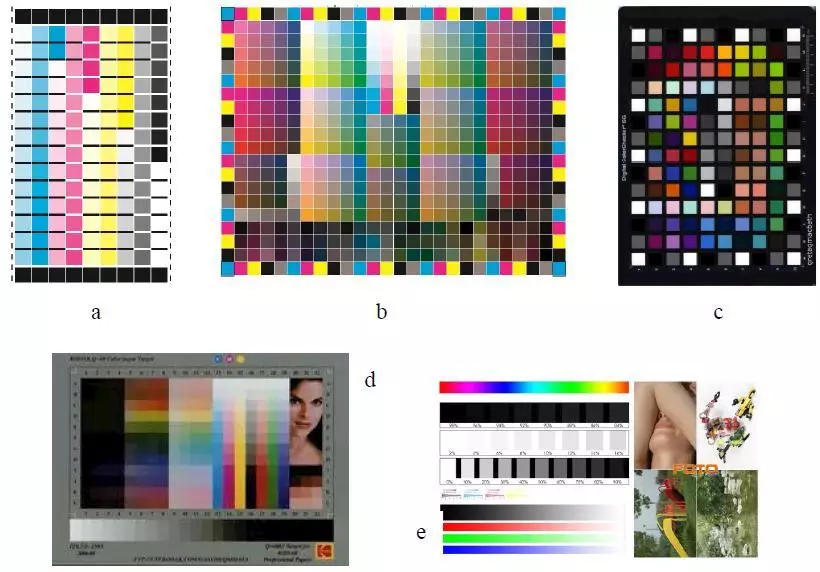

2. Characterisation is studying the behaviour of that device by sampling colour patches and recording the device response, see figure 2. This response includes characteristics of the device, colour gamut capability, etc. and this information is stored in a device profile.

3. Conversion is a process in which image is converted from one device profile to another device profile through CIELab conversion, see figure 1.

Figure 2 - Test chards (a) Printer calibration (b) Printer characterisation (c) Camera

characterisation (d) Scanner characterisation (e) Display monitor characterisation.

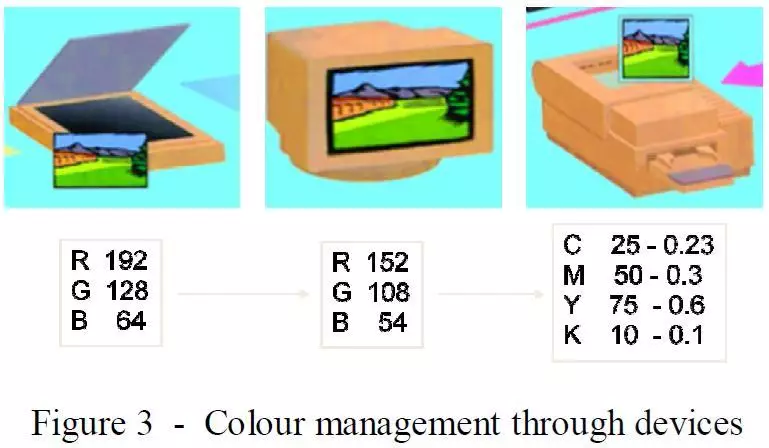

Once the calibration and characterisation is carried out device profiles are ready for regular production. It works as shown in figure 3. In the example in figure 3 colour scanner RGB values are converted through CIELab colour model to the monitor RGB values for display. Display RGB values are converted through CIELab colour model to printer CMYK dot percentages or print density values. CIELab colour model works as interpreter helps to get nearest colour match within the device capability.

The reproduction processes for variety of output systems vary very widely and each one has its own limitations on colour fidelity compared to the original images or designs. Within each process again there are innumerable variables, such as substrates, colorants, process variations, CMYK only or CMYK plus special colours, only special colours like Pantone, halftone methods and so on. Reproduction processes are :

1. Television

2. Computer displays

3. Litho-Offset

4. Letterpress

5. Flexography

6. Gravure

7. Screen Process

8. Digital printing (electrophotographic and ink jet)

Colour gamut compression is a method of reproducing the colours in the original design to fit into the output device colour gamut capability, whether display or hard copy print by a particular process. Colour gamut mapping is a method of compressing the colours the most appropriate and acceptable way. There are different methods of compression.

See All

See All