Uflex engineers multi-lane automatic linear pick-fill-seal machine

Packers for years have been grappling with the problem of narrow mouth opening of preformed flat bottom pouches or 3D pouches on the filling lines. The vacuum cups of conventional Pick Fill & Seal (PFS) machines clamp open a pouch by holding its two side gussets, thus resulting in a very narrow opening. This leads to rather sluggish filling of these pouches, without being able to have full mouth opening.

19 Dec 2016 | By Rahul Kumar

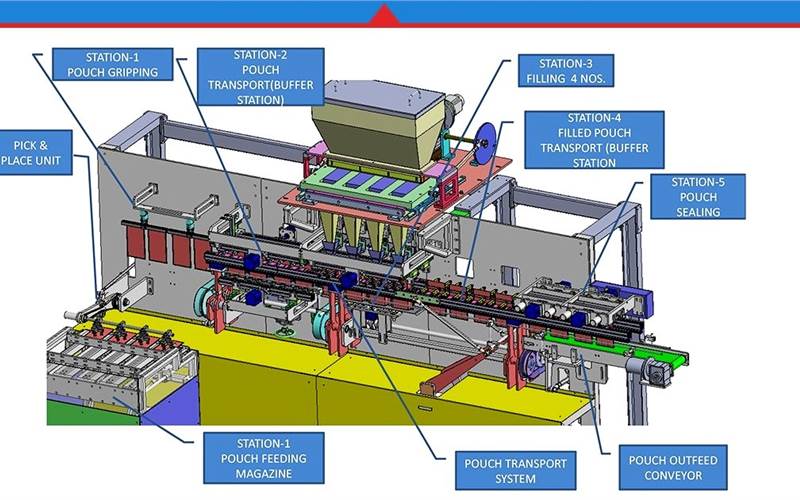

To overcome this, Uflex has engineered the multi lane automatic linear Pick Fill & Seal machine. The vacuum cups of this machine, unlike the conventional PFS machines clamp, open a pouch by holding its four Ps or the panels thereby opening up the mouth as wide as it gets.

Compared to any rotary PFS machine, the comparable speed of filling and sealing 3D/flat bottom pouches in this machine has more than doubled. Uflex is the only company in India to have indigenously engineered this simple and intellectually appealing machine. This machine can be equipped with Volumetric, Gravimetric or Liquid Filling systems.

The advantages of the machine are:

- Higher filling output rate (pouches/minute) of 3D/flat bottom pouches owing to wider mouth opening and the machine being multi-lane

- Since the mouth of the pouch is opened to the hilt, bigger sized products can be inserted, filled and sealed inside the 3D pouches

- The same machine can be used to fill doy pack/stand up pouches; three side seal pouches and normal zipper pouches as well

The features of the machine includes:

- It is a continuous machine designed for efficient packaging of various products like tea, sugar, salt, granular products, etc

- The machine is PLC controlled with touch screen HMI, making it operator friendly

- Five servo integrated to achieve high performance

- Versatile machine where the pouch sizes can be changed easily

- Accurate pick and place mechanism for exact position of the pouch

- Unique filling system

- Compact design with small footprint

- Easy operation

- Low maintenance

- Various optional attachments can be provided like nitrogen flushing etc as per customers’ requirement

Ajay Tandon, president and CEO, engineering business, Uflex, said, “This sophisticated machine is a classic example of interventional engineering by Uflex. Our customers approached us with the pain point of not being able to rapidly fill the 3D/flat bottom pouches. Some of them even filled up the pouches manually. It took us 15 months to engineer this machine at our plant in Noida.”

Ashok Chaturvedi, chairman and managing director, Uflex, said, “The flexible packaging industry has evolved rapidly and now, one can see the most innovative packaging solutions on the retail shelf. Flat bottom pouches or the 3D pouches are one of the most brilliant and efficient examples of modern day packaging. Owing to the unavailability of a suitable filling machine, the magic of these brilliant 3D pouches was somewhat restrained. I am glad that our engineering team at Uflex has created a machine that can ensure wider mouth openings of flat bottom pouches ensuring easy filling at much higher speeds and output rates. This in turn will give boost to the sale of flat bottom pouches. Having a stellar pouch without an appropriate filling machine is just like having a great car without tyres. Being the fully integrated flexible packaging materials and solution company, Uflex always ensure that pathbreaking packaging designs are complimented with the associated packing/filling machines.”

See All

See All