RS Graphics invests in Esko's Kongsberg and pre-press software

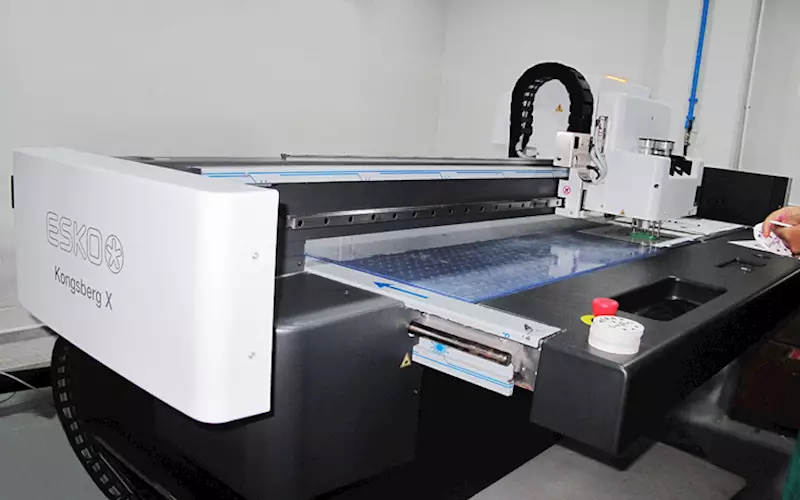

Chennai-based RS Graphics, manufacturer of cartons and labels, recently invested in a Kongsberg X Starter digital sample maker and three Esko pre-press software modules.

03 May 2019 | By Sujith Ail

VB Sridharan, managing director of RS Graphics, said, “There are other companies as well but nothing compares to the quality provided by Esko. I found the Esko software and the Kongsberg X to be most suitable for our requirements as these assist in faster turnaround of jobs and are extremely user-friendly.”

RS Graphics first installed Esko ArtiosCAD 3D, Deskpack Advanced and Plato followed by Kongsberg. ArtiosCAD 3D is used for packaging structural design software for corrugated boxes, folding cartons, POPs and FSDU design. With its library of templates and standards, the software helps in the structural design of any packaging with high precision.

Esko Deskpack Advanced is a collection of user-friendly packaging pre-press plug-ins for Adobe Illustrator and Adobe Photoshop. It helps in making graphics printable with professional tools and finesse.

Esko Plato is a tool for the creation of print-ready layouts with step and repeat and nesting for cartons and labels. It is the production gateway between the pre-press department and the pressroom.

The Kongsberg X Starter comes in standard configurations for sample making, signage and display production. Driven by Esko digital design software, it cuts and creases at a maximum speed of 50 meters per minute for quick samples of cartons, labels or finished POPs and signage on a variety of materials such as corrugated, folding carton, solid board, foam, spot coating blankets, wood and various types of plastics. Kongsberg is the most widely used cutting table in the packaging industry in India and world over.

Sridharan added, “We invested in the Esko Kongsberg because we do a lot of exports. Since we are in exports, we invariably need the samples faster, say within two days’ time or so. Traditionally, one first needed to make a die to make a box and that takes a lot of time and apart from the cost, there is a lack of flexibility in case there are changes. With the Esko Kongsberg, the carton sample is ready within half an hour. So it has helped us reduce our production time and saved us a lot of resources that go into the making of a die. The level of perfection achieved with the machine is 100% and we are extremely happy with our investment.”

VB Sridharan, managing director of RS Graphics

See All

See All