Pelican introduces made-in-India Cerutti R-982

Pelican has introduced the Cerrutti R-982 rotogravure printing press manufactured at its engineering facility in Rajkot, Gujarat.

08 Feb 2018 | By Rushikesh Aravkar

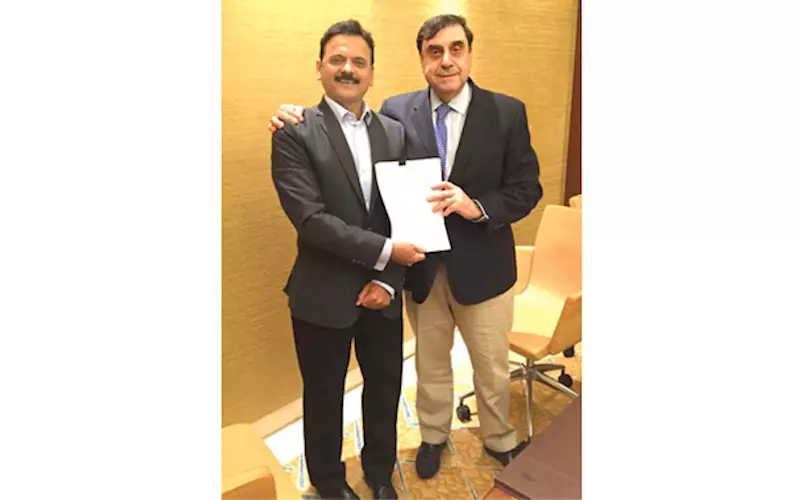

Cerutti Packaging Equipment (part of Cerutti Group) is a company fully controlled by the Cerutti family and is one of the key suppliers in the converting industry. Pelican is the largest rotogravure press manufacturing company in India. Both companies have entered into an agreement to manufacture Cerutti’s rotogravure press, Cerutti R-982 (with both, shafted and shaft-less cylinder chucking systems) at Pelican’s engineering facility in India for the Indian market as well as customers in the overseas territories.

Considering the “precision engineering ability backed by state-of-the-art infrastructure and strong family of 400+ highly competent technocrats at Pelican”, Cerutti Group has preferred Pelican as a perfect partner to share this technology to make in India.

Dr Giancarlo Cerutti, chairman and CEO of Cerutti Group, said, “India is one of the markets with the highest growth rate in the printing of packaging material and Cerutti has got a historical presence in such important area. Pelican is a company with long tradition in the manufacturing of equipment for the packaging industry with a solid reputation acknowledged by the market. We are of the opinion that the agreement of cooperation we sealed will represent an important benefit for the Indian converting companies, being the combination of high standard technology developed by Cerutti and manufacturing made by Pelican. We are very satisfied with the potential of this agreement that will contribute to further increase the presence of Cerutti in the Indian market.”

Cerutti will continue to offer to the Indian market all other equipment of its large portfolio both in the gravure as well in the converting fields.

Bharat Shah, CMD of Pelican, said, “It is a historic moment and a dream comes true. Pelican has strived a long way to reach at this stage and has applied unremitting efforts to build such state-of-the-art infrastructural facility and to developed such highly competent team of technocrats to ensures high precision engineering outputs. Due to having a stated proficiency only, Pelican can and has produced identical technology of Cerutti R-982 rotogravure press at the Pelican engineering facility and offering at a really competitive price.”

About Cerutti

Cerutti Packaging Equipment is a manufacturer of rotogravure presses for publication, packaging and specialities printing. Today more than thousand Cerutti printing presses, in the packaging field alone, are worldwide in operation; this endorses Cerutti as an accredited name in the packaging and publication industry. Cerutti has developed a rotogravure press that prepares anti-counterfeiting transparent window for the new polymer banknotes. These presses are covering almost the entire world need of such technology. In more recent times, new polymer five and ten Pound notes have entered into circulation in the United Kingdom and they are using Cerutti gravure presses; this safer window is core technology for printing new polymer banknotes. Cerutti has a highly skilled team of technologists dedicated to research and development and a strong engineering department, continuously working to develop new solutions aimed at higher productivity, better print quality, less waste, optimising ink solvent and energy consumption, faster job change over and enhanced automation to make ease in operation.

About Pelican

Pelican is one of the largest rotogravure press manufacturing company in Asia and is a pioneer in numerous technologies in India. Amongst many, Pelican is the first Indian company who has developed rotogravure press with electronic line shaft technology successfully in India way back in 2006. So far Pelican has successfully commissioned 500+ machines globally amongst which 60+ are ELS gravure presses. Pelican is a technology-driven company with engineering facilities at Rajkot (India). The company is well-equipped with clusters of very latest machinery to manufacture high precision machine parts and components.

See All

See All