Komori highlighted ‘innovate to create’ at Print China 2019

Komori's highlighted its theme ‘innovate to create’, and its KP-Connect Pro (Komori Solution Cloud) at Print China 2019 held at Guangdong, China from 9 to 13 April. The company showcased its offset as well as digital printing presses, printing materials and equipment. In short, the company’s focus was to work with printing companies to promote business innovation (innovate) that shifts people from the manufacturing to creating added value (create).

24 Apr 2019 | By Rahul Kumar

Komori has three new technological innovations that add digitalisation, automation and printing technology that the printing industry has nurtured, which is indispensable for the future manufacturing industry, that is, intelligence.

At the show, the company demonstrated the Lithrone G40 H-UV L (LED) mounted chrysanthemum full-size seven-colour offset sheetfed printing press with inline coater (GL-740 + C). So far, Lithrone G series package solutions have been introduced to many packaging printing companies in China and around the world.

According to the work instruction of KP- Connect Professional, the first job was printed at the maximum printing speed using the process four colours + special colour one colour + gloss varnish on the coated ball of paper thickness 0.45-mm, and the second job OP varnish + gloss varnish was used to express high value-added pseudo embossing. In the third job, the paper was changed to aluminum-deposited paper and white was printed on the first color, and OP varnish + gross varnish showed the possibility of in-line high value-added printing extending the width of the package work.

Komori also demonstrated the Lithrone G37 H-UV (GL-437), a full-colour four-color offset sheetfed printing machine, which can handle up to 636x939-paper size and is useful for a wide range of printing needs.

There was also a demonstration of the Premier IS29 29-inch single-wafer UV inkjet digital printing system. The Impremia IS 29 supports wide range of paper thickness and size, single-sided and double-sided printing, and can print high quality on various paper without special paper or pre-coat.

At Komori, under the brand name K-Supply, the company has a lineup of exclusive consumables, materials and equipment optimised for Komori printing machines. K-Supply is not just a consumable item, but a material developed by bringing together the knowhow of KGC (Komori Graphic Technology Center) to achieve high print quality and performance.

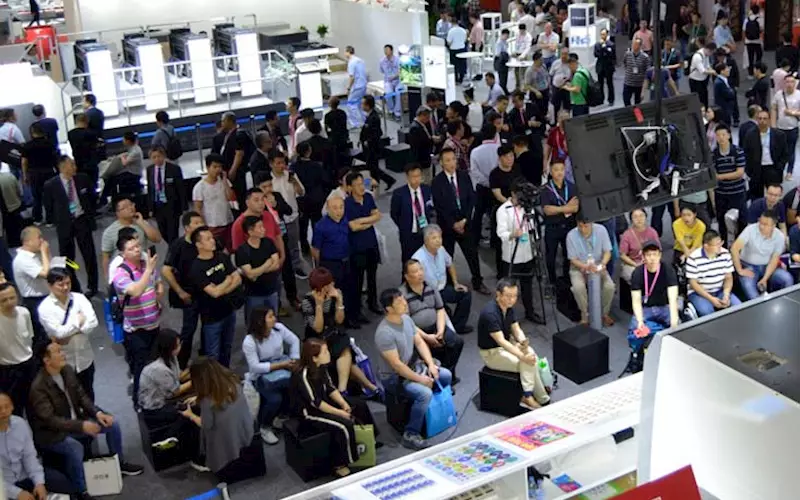

Accoridng to Sangam Khanna, deputy managing director, Komori India, the Komori stall received good crowd and the company was satisfied with the support they received from costumers.

“After PrintPack India 2019, Print China is the biggest push to Komori cause in the East Asia region. We will capitalise on the opportunities we have received in this five-day event. The presentation and response for packaging solutions presses was huge. So we are hopeful for a good year ahead in terms of Komori footprint in the region,” Khanna said.

See All

See All