The new OOH regulations and what needs to be done

The Municipal Corporation of Greater Mumbai has proposed a series of changes in the new outdoor advertising regulation. But are the changes a step towards the right direction in terms of ensuring workers safety, minimising the use of hazardous material, and promoting eco-friendly printing solutions? Abhishek Muralidharan digs deep

05 Apr 2019 | By Abhishek Muralidharan

Mumbai is set to implement a new outdoor advertising regulation, according to which hoardings on top of building terraces and rooftops will be banned. Also, hoardings that come under high-tension wires will be banned, unless the electricity board approves a no-objection certificate.

Meanwhile, a 10% rebate will be given on hoardings that have incorporated the use of solar energy, and also on hoardings with CCTV camera, as it will help the BMC control and monitor climatic operations.

According to the new regulation, the distance between hoardings will be increased from 20-m to 100-m.

The Municipal Corporation of Greater Mumbai (MCGM) has circulated a review of the policy guidelines on the grant of permission for display of sky-signs and advertisement under Section 328 and 328A of MMC Act 1888.

According to Sharad Bhaurao Bande, superintendent, licensing, MCGM, the new regulations have been suggested keeping in mind the safety of the public environment. “In 2015, we removed 30 hoardings which were classified under high-tension wires, and were unsafe for people near the airport land,” Bande said.

The municipal body has also discarded about 830 hoardings which did not adhere to the policy guidelines.

“The new policy ensures both public safety and environment-friendliness, and at the same time, it does not create any problems for the business entrepreneurs,” Bande said. “Also, we have taken efforts to bolster the use of digital hoardings in places like shopping malls, commercial buildings, multiplexes, and fuel stations.”

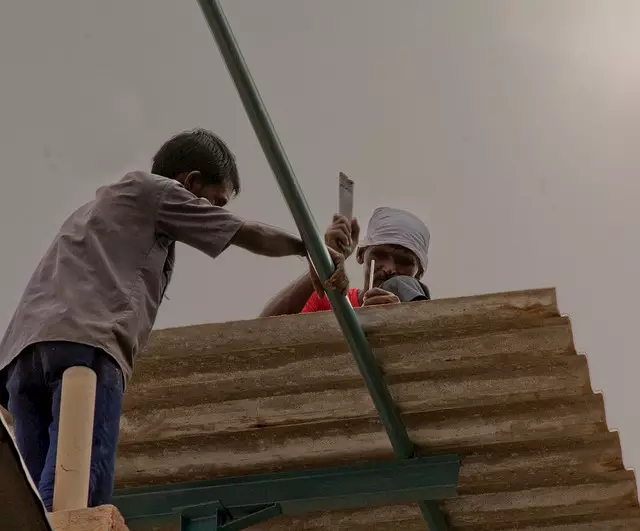

The question of workers’ safety

These are all the right initiatives. But where are immediate and long-term safety measures for the people involved?

We have often seen workers climb high-feet points for fixing, mounting and maintaining hoardings, without protective gears. Looking at the bigger picture, the solvent used in the manufacturing of flex and banners is harmful to people, especially to those handling them. Solvents can cause skin allergy; some solvents can even damage internal organs if exposed for a long period.

Also, PVC, being a polymer, is non-bio-degradable in nature and thus, needs to be burned for disposal. The toxins released when flex banners are burnt are carcinogenic, and during the disposal and treatment of theses PVC banners, toxic fumes and hazardous materials are in close contact with employees.

MCGM claims that the new policy has been drafted keeping in mind a few critical facets, such as empowerment of digital media, improvement of aesthetics, and considerations regarding public and environment safety.

However, the real question is, has the policy taken the right strides in uplifting public and environment safety on the basis of sustainable alternative and the workers’ benefits?

The answer involves three things. First, for the safety of workers, better equipment and facilities should be incorporated. Second, the policy should be stringent with its new rules regarding political hoardings. And, third, the use of eco-friendly inks and substrates should be encouraged.

In recent years, we have seen substantial developments in the field. For example, according to an IIT study, heavy substrates used for large-format printing are both recyclable and not as hazardous the thin ones. The thin ones that are below 250-microns, which are used in very large volumes, are both non-recyclable and hazardous to dispose of. Therefore, apt action is required to control this substance.

The government had passed a rule to discard thin vinyl for posters and banners, and society at large shares the same opinion for these thin vinyl banners. In fact, Bengaluru has already taken steps to discard it and it is being implemented in Maharashtra as well.

Alternative substrates

Sam Patel, director, Arrow Digital, says, “We are in close cooperation with textile companies in Gujarat and Mumbai and we have discovered that completely biodegradable materials like cotton and other such fabrics can be printed upon, especially for the out-of-home advertising industry.”

Also, Patel believes that this initiative of using textile as a substitute will not only empower the concept of making in India but it will also help make a profit in India. “Why to import a product for one dollar if the same green product can be easily made here for the same amount,” he said.

Arvind Advanced Materials is one such company which has been manufacturing fabrics which are PVC-free and recyclable. Abhishek Lalbhai of Arvind Advanced Materials says, “When we started developing a textile-based print media, which is PVC-free, it was not fully accepted. But we are confident that it will be a part of the entire value chain soon.”

According to Lalbhai, after facing various challenges, now the product is well established in the market. It received its biggest push after the blanket ban on PVC flex in Karnataka.

Another substitute substrate is obviously paper-based products. “Again, we are working with companies to develop paper-based boards that can easily be used as sun boards,” says Patel.

According to Patel, the corrugation industry can step in here. They can bring a profit-centred module for sustainability and development.

Powering OOH

Coming to the question of power consumption, the current accessories of the lamps used in OOH and signage industry consist of metal halide lamps, especially street lights, which are not strictly supervised or controlled on the lighting and non-working timers. This results in huge wastage.

Indrajit Sen of IOAA says, “There are excellent controls available today, using IOT technology and remote technology which control timers perfectly and also ensure that nothing goes off. Also, the cost of the entire thing is recoverable from savings alone.”

The new regulation provides a 10% rebate if solar panels are used, to encourage the use of solar energy to replace electricity. But, some encouragement on the use of the newest available technologies such as IOT can create wonders.

Santosh Nair of HP says, “The MCGM should focus on things such as the reverse economy. Halogens which guzzle electricity can be replaced by LED. Reverse economy, such as solar management can bring everything back to place.”

Nair believes that if sustainability is achieved, the circular economy will fall in place. “We are focusing on reverse engineering. For instance, we are trying to figure out the way the cartridge industry works where the cartridges are taken out, and how it can be recycled. So, step by step, we are trying to go green, first with inks, then material and other such alternatives," he said.

Flex isn’t going anywhere

Roughly 5% of the hoarding used for the OOH advertising industry is based on digital media; more than 90% is flex. So it is highly unlikely that it will disappear from the market anytime soon.

According to Sen, worldwide, only 7-8% of static displays have been shifted to digital. But since thick materials are a proven solution for recyclability and re-usability, static displays should not be a problem. The focus should be on getting rid of harmful inks and solvents. Sen proposes UV inks as an alternative solution.

So, there is already an alternative approach. But how feasible it is to execute? Is the print industry ready to print on these new substrates and use UV inks?

Starting something new comes with an added cost burden, which actually is proving deterrent to implementing the idea of sustainability.

Sen says, “We have spoken to various organisations and companies from Australia, Britain, and so on, to get a sense of the cost factors pertaining to the matter of eco-friendly printing, but sadly, worldwide, roughly two or three companies are ready to put their wallet where their mouth is.”

Nair adds, “When people talk about sustainability, they only speak about inks, but what about the base media? It's still flex. We can provide PVC-free solutions for even 30-40-feet panels where the entire end product is completely eco-friendly.”

The solution

According to Patel, for an alternative, printers are concerned about the premium on the funds the government provides. So, the approach should be to find a way to utilise those funds into the alternative process and make 10% or so profit.

He says solvents are a bigger problem than PVC, as use hazardous fillers, which, during rains, get separated and cause harm to the environment.

Nair says, “HP started finding water-based ink solutions a decade ago. The environmental issue is at every level. One needs to understand that. At HP, we are ready with worldwide recognised certifications that are imperative to achieve this printing process. We were the first ones to exit the solvent market about eight years ago.”

In the context, the Kornit Storm II machine, which offers direct-to-garment printing with water-based inks, can be an ideal solution. Patel says, “The Kornit Storm II machine enables a superior printing on multiple fabric types, including light and dark garments. The machine runs under an eco-friendly process complying strict standards.”

According to Patel, the usage of water-based inks has enabled Kornit Storm’s printing process to become 100% eco-friendly, as no volatile organic compounds are involved. Also, the garment itself is an eco-friendly material. “The direct-to-garment process doesn’t require any sort of pre-treatment, washing or streaming," adds Patel.

The equation is quite clear. For achieving a sustainable solution, government organisations, manufacturers and businessmen should work together.

Yes, we want a city that is aesthetically appealing and technologically advanced, but it should not be at the cost of the lives of the people involved. To conclude, the regulation is well-drafted, but improvements such as IOT, textile-based alternatives for PVC, and facilitating eco-friendly printing processes, will make it future-ready.

The data inputs were collected from a panel discussion at the SOTI conference held at Media Expo 2019

(l-r)Abhishek Lalbhai, Sam Patel, Sharad Bande, Indrajit Sen, Santosh Nair

See All

See All