The future is brighter, and now is the hour

The six print editions of WhatPackaging? offer a tour of the world of packaging in 2018. From top deals, to analysis of what makes packaging unique and relevant.

21 Dec 2018 | By Rushikesh Aravkar

In 2018, when we took the plunge to make WhatPackaging? a bi-monthly publication, which had seen four editions in the previous year, we were overwhelmed by the task at hand – the enormity of the packaging value chain, different packaging materials and an ecosystem around each, processes and techniques – the more we learnt about the industry, the less we knew for sure.

In the February edition, we took stock of the flexible packaging sector, BOPP and BOPET market and covered the Plast India show in Gandhinagar. We had reported: 10 high-end imported gravure printing machines in India in 2017; whereas around 70 locally manufactured presses were installed. On the CI flexo front, a total of 39 machines were installed in 2017 of which 12 are imported presses. Our sources tell us, another 12 imported CI flexo presses were installed in 2018 and five are in the pipeline.

The April edition focused on corrugation. We travelled to Bengaluru and Mysuru to see two corrugation factories operate – MNM Triplewall and South India Paper Mills. Since we were in Bengaluru, we met MTR’s chief marketing officer Sunay Bhasin to get a packaging perspective.

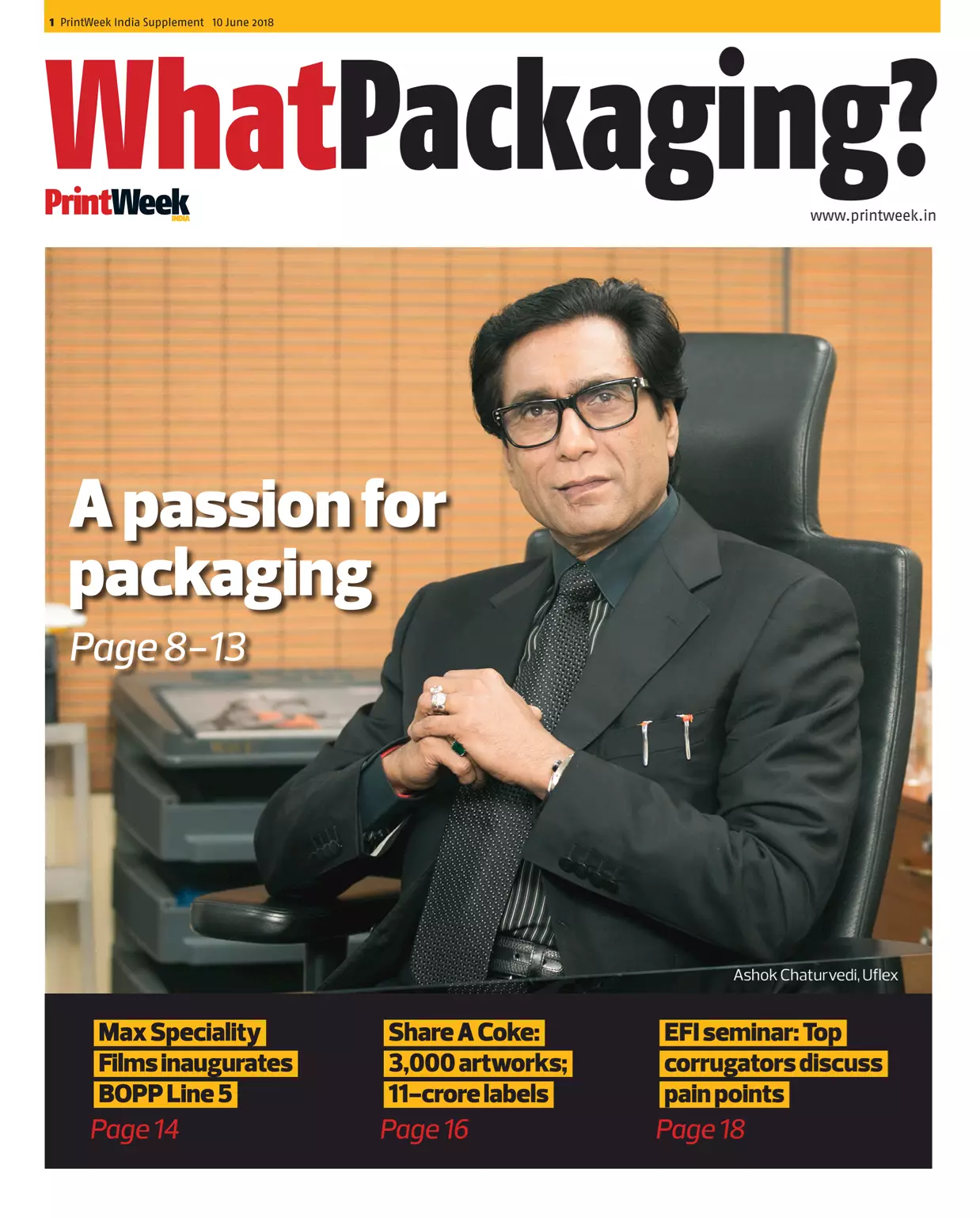

The highlight of the June edition was a Big Interview with Uflex’s chairman and managing director, Ashok Chaturvedi where he among other things makes a solid case for plastics against the blanket ban on the material. He says, “Had plastic not been invented, many regular, essential and luxury items that you see around yourself and use in your daily lives would have been made from plants either directly or indirectly. If that were to happen, our earth would have been bereft of its entire green cover.”

In the August edition, the spotlight was on food safety. We spoke to Pawan Kumar Agarwal, chief executive officer, Food Safety and Standards Authority of India, to make sense of the changing regulatory landscape surrounding the issue of food safety and packaging. We also spoke to food packaging converters, material and consumable suppliers and other stakeholders of the supply chain to dig deeper on what needs to be done to guarantee safe and wholesome food in India.

The cover story of the October edition was Rajkot-based Balaji Multiflex’s Rs 120-crore flexible packaging factory and the centrepiece of the factory is India’s first W&H Heliostar II S rotogravure printing press. It is a dream project for Pranav Bhalara who helms Balaji Multiflex. In an hour-long conversation, he divulges about he aspires to make the company a lighthouse to the Indian flexible packaging industry.

Another milestone for WhatPackaging? was the Masterclass knowledge forum that transpired on 29 November. It 100+ designers, marketers, brand managers and packaging development managers in attendance. The conversations focused on one aspect of packaging - its role in branding and marketing and how packaging can achieve a greater impact on the shelf for the products it contains.

The objective at WhatPackaging? Masterclass is to upgrade (and intensify) the conversations between the five stakeholders – manufacturers, material developer, designers, packaging converters, and brands – to strengthen technical cooperation and exchange expertise.

In this tenth edition of WhatPackaging? , you can catch the highlights of the Masterclass; a detailed reportage on Labelexpo; plus lots of consumer insights.

All this is just the tip of the iceberg. The more we write, the more there is to be written and said. But one thing is certain, the future is brighter and this is the hour of packaging.

We anticipate 2019 to be much more exciting and happening. Contact Rushikesh Aravkar at rushikesh.aravkar@haymarketsac.com to share your news, views and market moves with us.

See All

See All