Made in India: Newslight 40 Compact

Newslight 40 Compact helps big and small newspaper publishing houses to meet newspaper production demands more economically and faster, Saurabh Gupta of Prakash Web Offset explains to Rahul Kumar

24 Apr 2019 | By Rahul Kumar

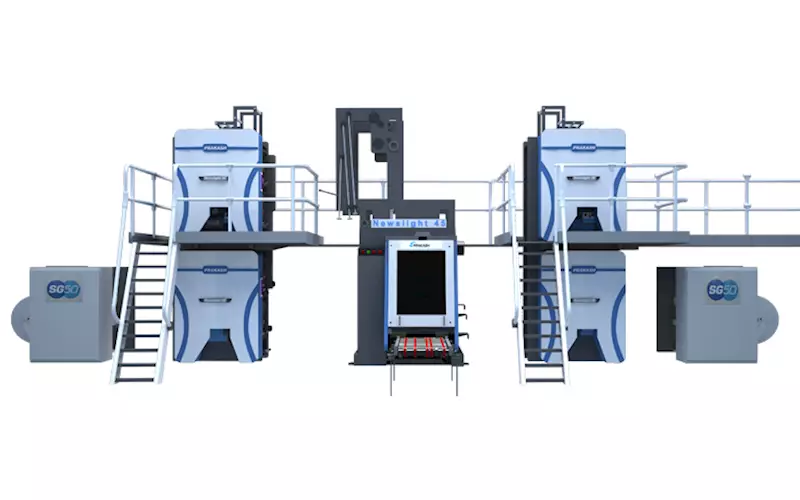

With print runs of newspapers getting shorter, and customers looking for a flexible solution, which is easy and economical, Prakash Web Offset, one of the leading manufacturers of web offset printing presses in India, developed the new Newslight 40 Compact specifically for newspaper production houses. The machine was launched in February 2019.

The Newslight 40 Compact, a 2x1 (single width single circumference) press with full automation options, and with a web width of 700-mm, can print 40,000 copies per hour.

“The machine’s smaller footprint, high automation level, and print stability make it a suitable newspaper production printing press,” says Saurabh Gupta of Prakash Web Offset.

Gupta adds that the machine was launched considering the price – and quality sensitive market that the newspaper industry has become. “The Newslight 40 is reasonably priced and its unique design features allow it to stand out in the market. With this product, the customer will get 25% power saving and lowest maintenance/ running cost. Its 700-mm width is exactly what industry wanted but it was not available to the customer until now,” Gupta explains.

An established player in the web offset market, besides India, Prakash has installed its machines in countries such as USA, Mexico, Brazil, Argentina, Nigeria, Tanzania, Sri Lanka, Bangladesh, Nepal, Egypt, and Sudan, among others.

In India, Prakash has over 2,000 print unit installations with all leading Indian dailies, including Dainik Bhaskar, Dainik Jagran, Rajasthan Patrika, Navabharat, Haribhoomi, Dabang Dunia, Nai Dunia, Amar Ujala, Sanmarg, among others.

Quality and affordability

Today, newspaper publishing houses want high-quality presses which are reasonably priced and can be serviced or maintained easily, sometimes without the engagement of the manufacturer. Also, high automation is very important as all printers want to save on labour cost and print wastage. Service support from OEM is another critical factor while choosing a web offset supplier.

Gupta says the new machine fulfils all the above requirements.

Prakash offers 24x7 remote assistance by connecting directly to the machine using its state-of-the-art software. “With this, we can easily diagnose and fix faults from offsite.

This has given us unparalleled advantage and value to the customer,” Gupta says.

Fast and easy

Newslight 40 Compact is the world’s first 700-mm wide 40,000-cph speed machine. These days, newspapers have to churn out several editions in an ever-shrinking printing time slot. Therefore, the speed of the press is very critical if a customer wants to print all its editions on time. Gupta says the distinct features of the machine, such as 700-mm width, bearer-to-bearer cylinders, helical gears, potentiometer-based registration system, shear key on drive shaft make it a high-quality printing press.

Typical applications include printing newspaper, textbooks, magazines, question papers with variable data, answers sheet with a bar code, pre-printed stationery, among others. “One of our customers printed gold (special colour) on coated paper on our four-colour web offset printing press. Online UV drying was used for curing during the production for quick drying,” Gupta says.

He adds that web offset printing in a Prakash machine is the simplest and cheapest form of printing in applications where voluminous printing is required in a short time. Also, Gupta says, web offset unique ability to fold and cut simultaneously, makes it the most attractive printing method.

Above all, Gupta says, Newslight 40 Compact is quite easy to use. As it has a width of only 700-mm, an operator can reach each roller and cylinder quite easily. All operations, such as plate loading, blanket fitting, roller cleaning can be done from the side of the machine, and there is no need to enter the machine by opening the covers. The complete gear train is oil bath and can be seen visibly from outside due to easy covers feature. This saves hours of opening gear side covers to perform routine maintenance.

Prakash also has an option of training customers’ operator in its factory during the machine assembly stage. “We have dedicated training modules, which equip machine operators and maintenance crew learn about the machine in depth. This helps the customer maintain machine uptime 100% at his site,” Gupta says.

Prakash pays close attention to its service network. All Prakash engineers are well trained and are available to the customer on call. “Plus, Newslight 40 comes with remote diagnostic features, wherein, our factory is always connected to the machine. All machine maintenance logs and production data can be viewed online. Newslight 40 comes with unique data logging feature and a customer is assigned unique IP address where the customer can also see machine critical parameters, stoppage times, production data and more,” Gupta says.

According to Gupta, the company received outstanding feedback for the Newslight 40 Compact during PrintPack 2019. “Our live demonstration of the machine was a show-stopper. We are already working on leads of over 40 towers. We hope in FY 19-20, we will be able to install 40-45 towers of Newslight 40 Compact,” Gupta concludes.

Specifications

Maximum mechanical speed: 40,000 impressions/hour

Pages per web: 4 broadsheet, 8 tabloid

Cut-off range: 533-mm, 546-mm

Maximum web width: 700-mm

Printing unit modules: ‘H’ type, eight couple tower

Plate lock up: toolless, slot type

Blanket lock up: narrow gap spindle type

Reel splicer: fully automatic SG 50

Maximum reel diameter: 1067-mm, 1270-mm

Folder: 2:2:2 jaw type

Drive system: mechanical shaft, servo shaftless

Customer testimonial

We are a long-standing customer of web offset printing presses from Prakash and are using multiple 24-coloured pages machines. We are satisfied with the print quality and after-sales service.

Rakesh Bhandari, Rajasthan Patrika

Prakash Web Offset has been associated with Jagran Prakashan from the last several years. We are using Prakash presses, load-bearing autopaster SG50 at our printing centres. We have a good experience with the company.

SK Singh, Dainik Jagran

We work closely with Prakash Web Offset. We were the first one to trust its Newlight line of machines and placed orders for multiple 24-colour pages machines. We are happy with the product and its performance. Prakash’s inclination towards innovation and the technology is admirable.

Dinesh Sharma of Dainik Bhaskar

We are using Prakash’s machines at our multiple locations, not only the printing presses but also turner bars, autopaster and web cleaner. I can confidently say that Prakash has proven to be a strong player in the industry by offering, innovative products and by maintaining good quality standards.

Pradeep Unny, Amar Ujala

See All

See All