Made in India: Mannat ERP solution

Mannat is a customised ERP solution. As it’s an indigenous product, it is more competitive compared to other available solutions, explains Bhuvnesh Joshi, managing partner, Mannat Print Management Solutions, to Rahul Kumar

19 Oct 2018 | By Rahul Kumar

Mannat, developed by Ahmedabad-based Mannat Print Management Solutions, is a customised ERP solution for printing and packaging industry. According to Bhuvnesh Joshi, managing partner, Mannat, the ERP is ready for commercial printers, folding cartons manufacturers as well as flexible printing products manufacturers and digital printers.

Mannat is a web-based solution, using PHP for frontend My SQL for the backend. It offers businesses a competitive edge by dramatically improving front and backend operations and management, from sales enquiry to process profit and loss of each and every order.

The solution was launched in October 2015.

Joshi says investing in an ERP solution is like investing in a term plan or health plan. “Printers who understand technology are adopting ERP and they have benefited as well,” Joshi says.

He adds that Mannat, being an indigenous solution, is very competitive compared to other available solutions with equivalent depth and features. “It saves anywhere between 3-4% of turnover for any converter if implemented properly,” he says.

So far, Mannat has 28 installations across India. Some of the key customers include Nebula Home Products, Goa; Manohar Packaging, Goa; Saptagiri Packaging, Silvassa; Nimbus Packaging, Vapi; Wee Pac, Surat; Wikas Packaging (Sakal Group), Nashik; Rushab Print Pack, Vadodara; Dev Print Pack, Ahmedabad; Popular Printers, Jaipur; MJ Global, Noida; Tirupati Polymers, Kalaamb and Dimple Packaging, Ludhiana.

The solution

Joshi says for an ERP solution to work, the interface should be user-friendly and it should take minimum effort to adapt. “Secondly, the ERP should cover all manufacturing processes in depth and should deliver reports promptly,” he adds.

On the USP of the Mannat solution, Joshi says it is a web-based solution. Thus, it can be accessed from anywhere. Thus, a user can offer limited and controlled access to all stakeholders, and can achieve minimum communication ecosystem and save a lot of time and energy.

Again, one can do costing in the system using two methods. One is estimate, which is conversion base of operations prices and the other is the manufacturing cost sheet, which is conversion based on hourly base price.

Joshi says the solution uses verticals-modules-user (VMU) approach.

There are several alternatives available in the market. These include EFI, Param ERP, Renuka Softech, Easy Print, Penta Force, Finsys, among others.

“Ours is a web-based solution. Thus, our solution is operating system-free. You can access it wherever browsing is available,” Joshi says. “It has been developed by print technocrats having experiences of almost two decades. So ours is a very hands-on solution which is close to practical environment and its needs.”

Another advantage, Joshi says, is that it covers all four verticals of printing industry, commercial, folding cartons (mono, fluted and liner), flexible packaging products (labels, lamitubes, laminates and shrink sleeve, etc) and rigid box as well.

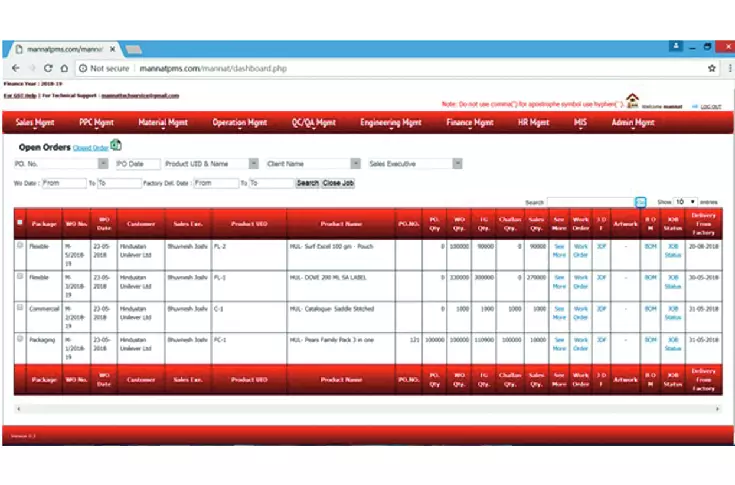

A screenshot of the Mannat dashboard

Focused on productivity

“The focus of any ERP solution is always on productivity,” Joshi says. “We take note of suggestions from our customers, and with every new development, we have bettered our productivity targets.”

He says the solution is easy to use and anyone with basic knowledge of MS Office can run it easily. “We have made it even simpler at machine operator level. Operators can fill their production data through mobile as well as tablet. It is not a challenge anymore as everybody operates smart phones these days,” he adds.

The company also provides training based on module or departments. Generally, two working days of training is sufficient for one department. For all modules, 16 working days of training is provided.

On the shopfloor

Joshi gives the example of one of Mannat’s customers, who started a packaging unit with a huge investment in new machines. “The company has been using our solution from day one. It’s been two and half years now and they are doing well and they use our ERP religiously and they confess that investing in ERP was a good decision. They got ISO easily due to their vision for system-oriented approach and reports generated by ERP do assist their working environment. Secondly, they always get appreciation in QC audits,” Joshi says.

According to Joshi, one of the best practices on a shopfloor is that SOPs must be defined and adhered to. “In most presses usually seniors or management people jump the queue. Hence, self-discipline is a must for any organisation,” he adds.

On the industry trends, Joshi says, the industry is still not willing to spend on software. “Most look for cheaper options or crack-versions. Thankfully, when it comes to ERP, piracy is not a concern, but yes, investing in an ERP is last priority,” he says.

Customer Testimonials

We have been growing exponentially . And so, we needed a robust and integrated IT backbone that is flexible and scalable to meet all our needs. We evaluated multiple global ERP solutions and chose Mannat as it fits our requirements like a glove. A powerful solution coupled with competent implementation team enabled a smooth transition to ERP in record time. We look forward to a continued association with MPMS.

Nebula Home Products, Goa

We have been using Mannat for the last three years. We are fully satisfied with the qualitative and time-bound post-sales services offered by the company. The software has transformed our day-to-day working miraculously to make our company more organised and automated.

Popular Printers, Jaipur

See All

See All