Imran Shekh: Proud to be nominated at Fespa 2019

Rajkot-based manufacturer and printer, Imran Shekh, speaks to PrintWeek India about his print journey with his partner Viraj Patel and creating a window-binding and twin-side lamination machine, as well as a spot-foiling machine.

13 Mar 2019 | By Abhishek Muralidharan

When did you start your career as a printer?

It all started as a screen operator in Rajkot. At a young age, I understood the importance of harnessing printing technology. So I took a bank loan and started manufacturing frames and UV dryers which is registered under the brand name Indicot.

What type of machine have you developed?

We have developed machines such as window-binding machine and twin-side lamination machine. However, according to me, the spot-foiling machine we have developed inspired by a digital foiling machine is standout.

Why so?

For its production of spot-foil for boxes and labels. The machine can produce 1,200 sheets per hour.

Explain the key features of this machine?

We believe that smaller machine can do long pulling jobs but bigger machines can't do short run jobs. Due to the 15x20 machine size, many people who were interested in UV printing but had small budgets didn't get a chance to grab this opportunity. With our UV machine, we provide our customers with customers can short-run jobs such as 1000-2000 boxes/labels, also, this enables cost-reduction as the plate charges drop.

This new idea of doing old business has helped many companies grow, who needed small quantity jobs but with high quality (spot foil printing, UV drip-off printing and transparent labels)

When did the Insta Print Pack’s journey begin?

Five years ago, I met Viraj Patel, who lived in the US, but was surveying the Indian printing industry and its volume. We waited for almost a year to get the right machine. Finally, we opted for the Heidelberg SM-52, which focuses on UV printing. Along with it, we acquired additional packaging equipment.

What is your production capacity?

Our factory has a floor area of 900-sq/ft. We have a production capacity of nearly 40,000 sheets per day. We work for 18 hours a day and clock a turnover of Rs 3-crore.

Your biggest achievement at Insta Print Pack?

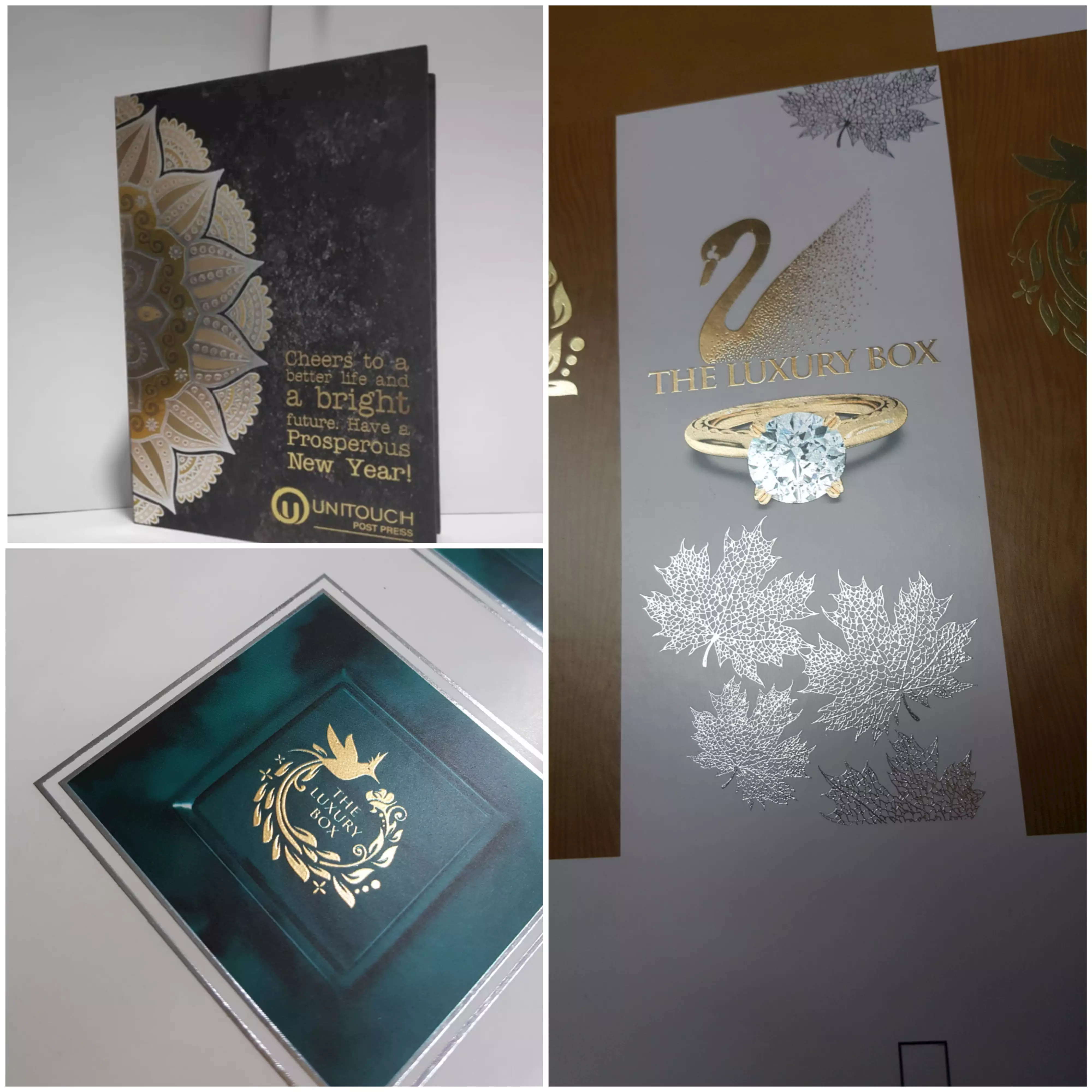

Fulfilling the requirements of Khadi’s cosmetic brand was a huge achievement for us. Also, with the help of the new spot-foiling machine, we have made a calendar which was nominated during Fespa 2019.

What next for Insta Print Pack?

We have set up branch offices at Ahmedabad, Indore and Haridwar. Now we are looking to expand.

The samples nominated for Fespa 2019

See All

See All