Green inks: Not so black and white

Sherry Washburn, supplies business unit manager at Videojet Technologies, takes a closer look at the green aspects of industrial printing inks and asks: can they ever be truly green?

18 Apr 2019 | By PrintWeek India

Industrial printing inks are increasingly being billed as ‘green’, but what does that mean in reality? How does being green identify with industrial fluids? And are these claims simply paying lip service to those looking to make a positive impact in terms of the inks and make-up fluids they use? There is no clear definition or standard on what it means to be a ‘green’ ink.

Manufacturers, in order to keep up with demanding production schedules, require fast dry times and excellent adhesion, which involves the use of solvents such as ketones and alcohols. These fast-drying industrial solvents are flammable, volatile, organic compounds (VOCs); therefore, industrial inkjet inks are starting out with a hazardous material that is not necessarily in keeping with the notion of being ‘green’. VOCs are heavier than air, contribute to ground level smog, and some VOCs participate in photochemical reactions in the atmosphere that cause damage to the ozone layer.

Even though VOCs are hazardous, they are everywhere including in gasoline, ethanol used in vodka, and even isopropanol (IPA) in medical wipes. Anything that evaporates and contains carbon is classed as a VOC and so we are all in contact with them in some form or another throughout the course of everyday life.

Sherry Washburn, supplies business unit manager at Videojet Technologies

What can be done to make inks ‘greener’

There are three approaches to making a ‘greener’ ink; water-based, safer solvent, or Corporate Social Responsibility (CSR) goals. The first approach is using water, which is VOC-free. However, water evaporates so slowly that the dry time experienced on production lines will be longer than manufacturer requirements. If there isn’t sufficient time available during the coding and marking process, then the ink would need drying assistance. Additional energy would be consumed with this approach which negates its ‘green’ benefits.

If a water-based solution is not feasible, a second approach would be to utilise a safer solvent, acetone, which is exempt from the US Environmental Protection Agency (EPA) Clean Air Act. Acetone does not participate in photochemical reactions in the upper atmosphere; therefore, it does not deplete the ozone layer. Another option is to formulate with ethanol which has low odor and frequently found in the food and beverage industry. Ethanol has been used throughout human history safely for a variety of applications.

The last approach involves ink formulations which meet company CSR goals such as nocarcinogens, mutagens, reproductive toxins (CMRs), food contact materials, or controlled substances.

If we break inks down into their constituent parts, there are areas that can be targeted in terms of making them less of a ‘toxic’ fluid. Manufacturers should review ink constituents for all hazards, particularly CMRs. It can be desirable to remove ink constituents that are classified as CMRs and to replace them with an alternative, and it is possible to do this without having an impact on application performance.

Videojet has a long-standing policy not to use CMRs in its new development process. Environmental, health, and safety reviews are completed on every ink constituent before it is allowed to be used in new ink development. The inks and fluids we produce do not contain CMRs and could be deemed to be ‘greener’. The issue here is that there is no concrete definition as to what ‘green’ means; therefore, our own preference is to not use the term at all. Rather, we prefer to promote the fact that we are able to help our customers reach their own respective goals in terms of CSR.

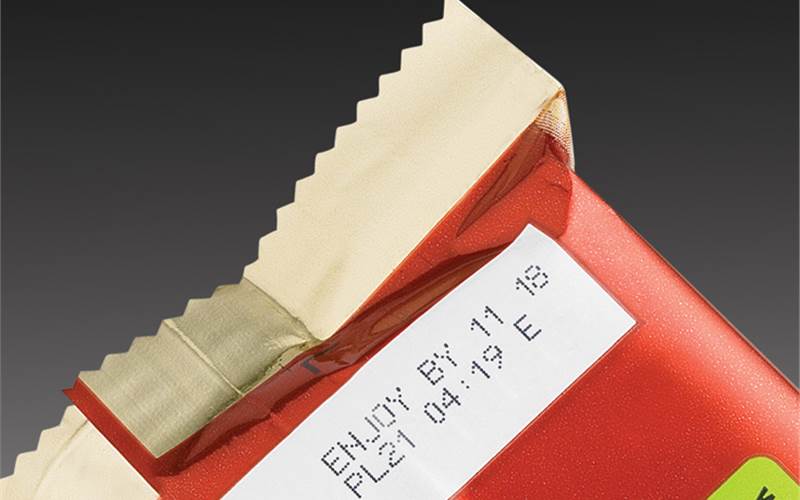

Manufacturers should look to expert suppliers of inks and fluids that work closely with customers to learn what is important to them with respect to their CSR goals. Most commonly, we are asked for no MEK, low odor, and inks that are suitable for food packaging. In order to make these more easily identifiable, they have been classified under iQMark. The proliferation of requirements that customers have to consider continues to grow exponentially, and we see it as our responsibility as a supplier to support them as closely as possible where CSR and compliance are concerned. iQMark simplifies the way supplies are ordered in terms of how they fit in with individual CSR goals and makes the process of identifying and selecting inks as seamless as possible. In addition, the ink delivery method of certain systems can contribute to CSR goals. Empty Smart Cartridges are not only recyclable, but they also are no longer hazardous materials.

Data sheets are readily available that enable the regulatory landscape to be factored into the selection process. Legislation such as the Swiss Food Packaging Ordinance, the Clean Air Act (US), and a number of similar acts implemented globally can be quickly identified and assurances provided that the ink is in compliance.

The question is not, is it green

When considering the best possible industrial inks for a production line, the question of whether that ink can be considered green is always going to be vastly open to interpretation. If an ink is marketed as ‘green’ then there are other questions that should follow. What is its composition? Does it contain a VOC? If not, will it be suitable for the line speeds required? Will drying assistance be necessary?

As we have mentioned, the word ‘green’ is open to interpretation. Therefore, it is far better to select inks and fluids based on how they integrate with a company’s own CSR goals and strategies, coupled with regulatory requirements. Through working with an expert supplier, every element that feeds into those CSR frameworks can be closely scrutinized and the best possible outcomes delivered.

See All

See All