CTP update - Indian newspapers embrace green platemaking

While reducing carbon footprint seems to be a top priority for Indian newspapers, the CTP sales are bullish. PrintWeek gets an update from the three biggies: Kodak, Fujifilm and TechNova.

14 Sep 2016 | By PrintWeek India

Computer-to-plate (CTP) systems as a rule, work rather well. They differ in features, speed, automation, and, of course, laser type, but most of them can reliably image a plate and produce a quality printable dot.

The plate manufacturing technology and the plate processors have evolved. It is not merely a game of coating the aluminium sheet with the light sensitive coating solution.

S M Ramprasad, assistant vice president of the India operations at Fujifilm says, “Today, lot of the print quality depends on the plate and how they are processed. The run length and dot reproducing ability are considered to be an important factor for any quality printing in offset.”

The newspaper players continue to rationalise and increase the efficiency of the production process as CTP technologies continue to mature.

CTP sales are bullish. In the last one year, Fujifilm has expanded its presence with more than 20 publications using Fujifilm products upping the tally to 40+ major newspaper and publication plants. While Kodak’s thermal CTP install base in the Indian newspaper segment is 150+ units. And TechNova has 350 iCTPs, 510 violet and 50 thermal installations in the newspaper segment.

One of the Kodak CTP-user across its centres, Eenadu recently added a couple of CTP machines to support the printing of additional colour pages, taking their tally of Kodak thermal CTPs up to 50 units.

A green thrust

Chemistry-free plate is one of the important innovations in recent times to simplify the platemaking process. It eliminates the process of plate development, which means that one of the main variables affecting image consistency is eliminated.

There has been a lot of traction in the newspaper segment with regards to reducing carbon footprint and adopting green printing solutions.

Ramprasad claims to have more than 10 newspapers adopting Fujifilm’s low-chem violet solutions.

Ramprasad adds, “For newspaper printing, Fujifilm has an advanced range of pre-press and pressroom solutions. Our primary plate production solution is built around our low chemistry CTP technologies and consists of a powerful and scalable newspaper workflow, wNewsNet, a range of platesetters and finishing units, and our range of Pro VN ‘lo-chem’ plates.”

“Fujifilm has the rate distinction of successful customers across both green thermal and green violet plate technologies with our completely processless thermal application like our Pro T3 used at a well-known publication in the South as well as in the Eastern Market.”

VRL Media’s newspaper, Vijayavani, one of the most widely circulated newspapers in Karnataka and the only all-colour Kannada newspaper operates 22 Kodak thermal CTP platesetters to support production. Kodak’s marketing manager Hersh Lulla informs that VRL uses Sonora processfree thermal plates. “As of 2016, their print production has shifted entirely to Sonora.”

Lulla cites two major factors that lead VRL towards Sonora. “One, VRL’s drive to implement environment-friendly set-up. Here, Sonora eliminates all chemistry and water for processing, as well as the use of electricity in processing since you totally eliminate the processor and secondly, streamlining operations by doing away with any processing variables and personnel to manage the processing of plates. A direct contribution to their bottom line re-affirms their stand on the decision to go processfree.”

By the end of 2015, almost about 50% of Indian newspapers had opted for chemistry-free plates. Amit Khurana of TechNova says, “Some of them have fully converted and rest are in process of moving to 100%. In India, TechNova’s VioGreen plates have been adopted by newspapers majors like Hindustan Group, Dainik Bhaskar, Rajasthan Patrika Group and Lokmat Group.”

According to Khurana, Lokmat has saved 1.5 million litres of water and 12,000 litres of chemistry after having adopted TechNova’s VioGreen Plus plates.

Green CTP plates

Fujifilm Brillia PRO-VN

It is a low-chemistry violet CTP plate specifically developed for the newspaper market. It uses Fujifilm’s ‘high sensitivity polymerisation’ technology, enabling newspaper printers to achieve the same levels of productivity as they achieve with conventionally processed violet CTP plates (without the need for laser upgrades).

TechNova VioGreen

VioGreen is a violet photopolymer digital plate that is imaged on a platesetter and then goes straight to the press after gumming. The expensive plate processor itself is no longer needed. VioGreen plates can be imaged on any standard violet CTP platesetter. The platesetters offered by TechNova include: Agfa Advantage N; VioStar News, VioStar KSSA and the Alinte VN 20.

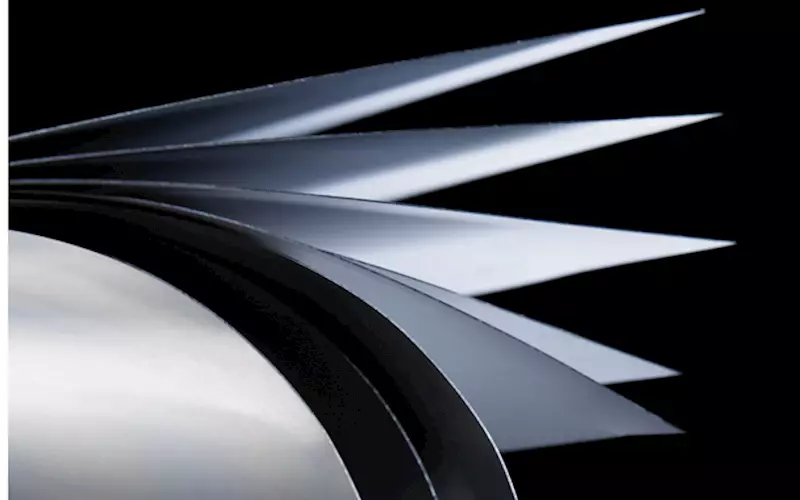

Kodak Sonora

Sonora plates are completely process-free, meaning there is no processing step, no chemistry and no processing equipment. The plates are simply imaged on the CTP device and can go straight to press. Sonora plates combine the benefits of process-free with excellent visibility of latent image, making operators’ lives easy, just like mainstream plates.

See All

See All